A method for treating yellowing of aluminum alloy ingot surface

A technology for ingot surface yellowing and aluminum alloy, which is applied in the field of aluminum alloy casting, can solve problems such as surface defects, affecting the appearance and processing quality of aluminum alloy ingots, and yellowing of aluminum alloy surface, so as to reduce impurities, strong hygroscopicity, Effect of reducing gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

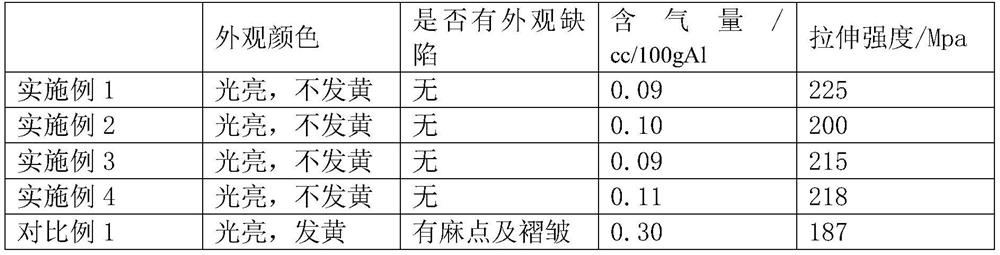

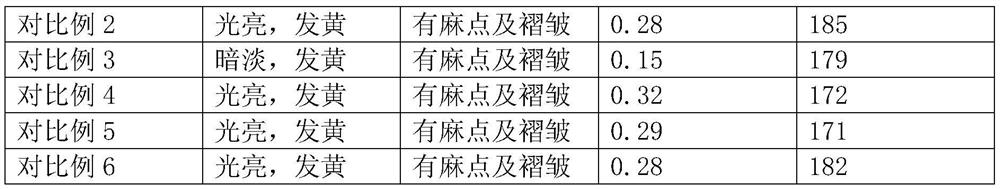

Examples

Embodiment 1

[0032] Aluminum alloy is AlSi9Cu3 (Fe) aluminum alloy in the present embodiment

[0033] (1) Preparation of aluminum alloy melt:

[0034] Mix and melt the 5182 aluminum alloy raw materials, add 0.5% hexachloroethane of the total weight of the aluminum alloy raw materials, stir once every 15 minutes after adding the hexachloroethane, and stir for a total of 4 times; keep the melting temperature constant, and pass in Ar gas, The rate of feeding Ar gas is 0.2m 3 / min, refining for 10min, covered with flux to obtain aluminum alloy melt;

[0035] Wherein, flux is by the KCl of 50% by mass percentage, the NaCl of 25% and the NaCl of 25% 3 AlF 6 composition;

[0036] (2) Cast aluminum alloy ingot:

[0037] Keeping the temperature of the molten state constant, add a mixture of 0.08% of the total weight of the aluminum alloy raw material sodium fluoride, 0.6% of the total weight of the aluminum alloy raw material and a mixture of nickel chloride and copper chloride, wherein nickel...

Embodiment 2

[0039] Aluminum alloy is ADC12 aluminum alloy in the present embodiment

[0040] (1) Preparation of aluminum alloy melt:

[0041] Mix and melt the 5083 aluminum alloy raw materials, add hexachloroethane with 1% of the total weight of the aluminum alloy raw materials, stir once every 5 minutes after adding the hexachloroethane, and stir for a total of 3 times; keep the melting temperature constant, pass in Ar gas, The rate of feeding Ar gas is 0.18m 3 / min, refining for 8min, covered with flux to obtain aluminum alloy melt;

[0042] Wherein, flux is by the KCl of 50% by mass percentage, the NaCl of 25% and the NaCl of 25% 3 AlF 6 composition;

[0043] (2) Cast aluminum alloy ingot:

[0044] Keeping the temperature of the molten state constant, add a mixture of 0.07% of the total weight of aluminum alloy raw materials sodium fluoride, 0.5% of the total weight of aluminum alloy raw materials and copper chloride, wherein nickel chloride The molar ratio with cupric chloride i...

Embodiment 3

[0046] Aluminum alloy is 356 (Sr) aluminum alloy in the present embodiment

[0047] (1) Preparation of aluminum alloy melt:

[0048] Mix and melt the 7050 aluminum alloy raw materials, add hexachloroethane with 0.7% of the total weight of the aluminum alloy raw materials, stir once every 10 minutes after adding the hexachloroethane, and stir for a total of 5 times; keep the melting temperature constant, and pass in Ar gas, The rate of feeding Ar gas is 0.25m 3 / min, refining for 7min, covered with flux to obtain aluminum alloy melt;

[0049] Wherein, flux is by the KCl of 50% by mass percentage, the NaCl of 25% and the NaCl of 25% 3 AlF 6 composition;

[0050] (2) Cast aluminum alloy ingot:

[0051] Keeping the temperature of the molten state constant, add a mixture of 0.06% of the total weight of aluminum alloy raw materials sodium fluoride, 0.6% of the total weight of aluminum alloy raw materials and nickel chloride and copper chloride, wherein nickel chloride The mola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com