Preparation method of polycrystalline silicon wafer texturing liquid and black silicon material and its application in accelerating the letid recovery of perc battery

A technology for polycrystalline silicon wafers and texturing liquid, applied in chemical instruments and methods, sustainable manufacturing/processing, circuits, etc., can solve the problems of complicated steps, high cost, environmental pollution, etc. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A polysilicon texturing liquid, the preparation method is as follows:

[0058] (1) Take 1 mL of PNVA aqueous solution and dissolve it in 8 mL of water;

[0059] (2) Take 16mL of HF aqueous solution, Mn(NO 3 ) 2 64mL of the aqueous solution, join in the solution that step (1) obtains, mix uniformly, obtain polysilicon texturing liquid (wherein, the molar concentration of HF is 4.24mol / L, Mn(NO 3 ) 2 The molar concentration is 3.1mol / L).

[0060] A kind of black silicon material, preparation method is as follows:

[0061] (1) Place the prepared polysilicon texturing solution in a constant temperature water bath at 25°C;

[0062] (2) Etching the polysilicon wafer in the above-mentioned polysilicon wafer texturing solution for 3 minutes;

[0063] (3) Cleaning the etched polysilicon wafer by RCA standard cleaning method to remove impurities and drying to obtain black silicon material.

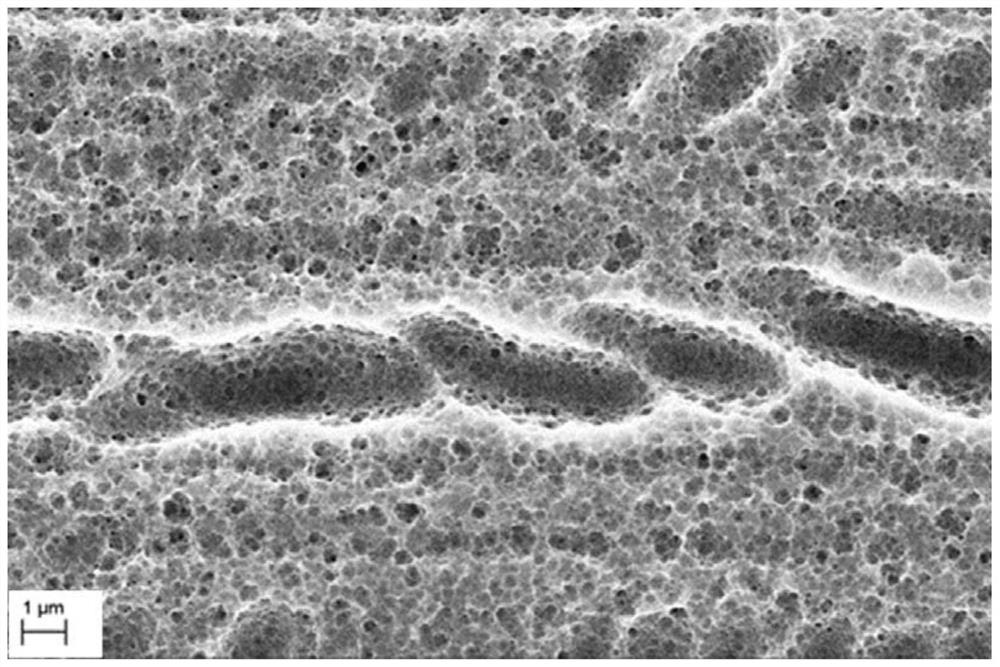

[0064] figure 1 It is the scanning electron micrograph of the black silicon mater...

Embodiment 2

[0066] A polysilicon texturing liquid, the preparation method is as follows:

[0067] (1) Take 8 mL of PNVA aqueous solution and dissolve it in 16 mL of water;

[0068] (2) Take 16mL of HF aqueous solution, Mn(NO 3 ) 2 64mL of the aqueous solution of HF, join in the solution that step (1) obtains, mix uniformly, obtain polysilicon texturing liquid (wherein, the molar concentration of HF is 3.63mol / L, Mn(NO 3 ) 2 The molar concentration is 2.6mol / L).

[0069] A kind of black silicon material, preparation method is as follows:

[0070] (1) Place the prepared polysilicon texturing solution in a constant temperature water bath at 15°C;

[0071] (2) Etching the polysilicon wafer in the above-mentioned polysilicon wafer texturing solution for 3 minutes;

[0072] (3) Cleaning the etched polysilicon wafer by RCA standard cleaning method to remove impurities and drying to obtain black silicon material.

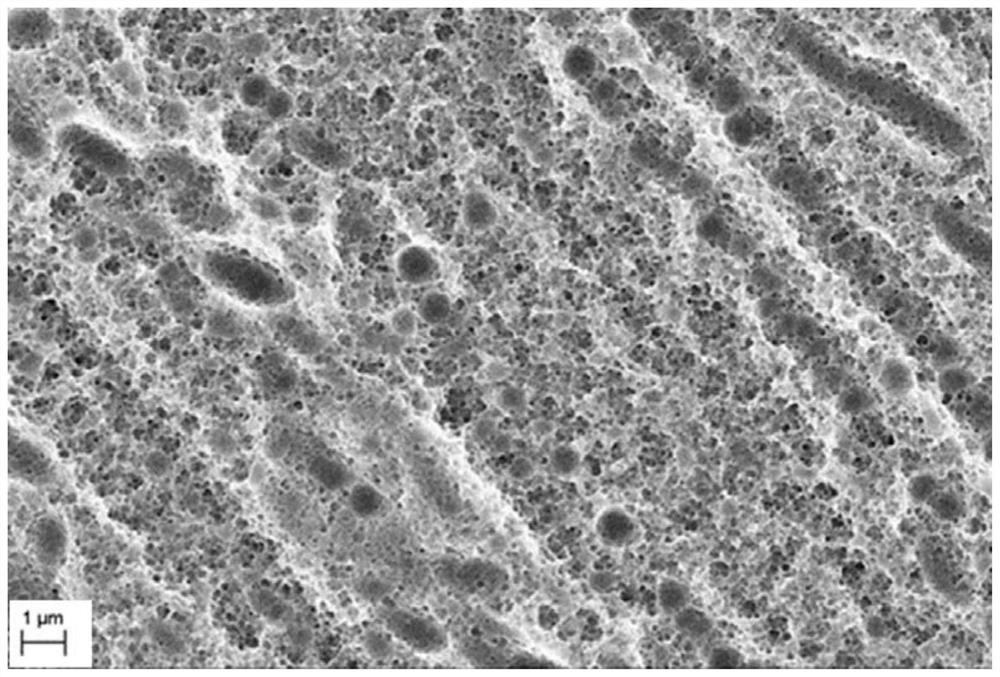

[0073] figure 2 It is the scanning electron micrograph of the black silic...

Embodiment 3

[0075] A polysilicon texturing liquid, the preparation method is as follows:

[0076] (1) Take 4 mL of the aqueous solution of PNVA and dissolve it in 8 mL of water;

[0077] (2) Take 16mL of HF aqueous solution, Mn(NO 3 ) 2 64mL of the aqueous solution, join in the solution that step (1) obtains, mix uniformly, obtain polysilicon texturing liquid (wherein, the molar concentration of HF is 4.24mol / L, Mn(NO 3 ) 2 The molar concentration is 3.1mol / L).

[0078] A kind of black silicon material, preparation method is as follows:

[0079] (1) Place the prepared polysilicon texturing solution in a constant temperature water bath at 18°C;

[0080] (2) Etching the polysilicon wafer in the above-mentioned polysilicon wafer texturing solution for 1 min;

[0081] (3) Cleaning the etched polysilicon wafer by RCA standard cleaning method to remove impurities and drying to obtain black silicon material.

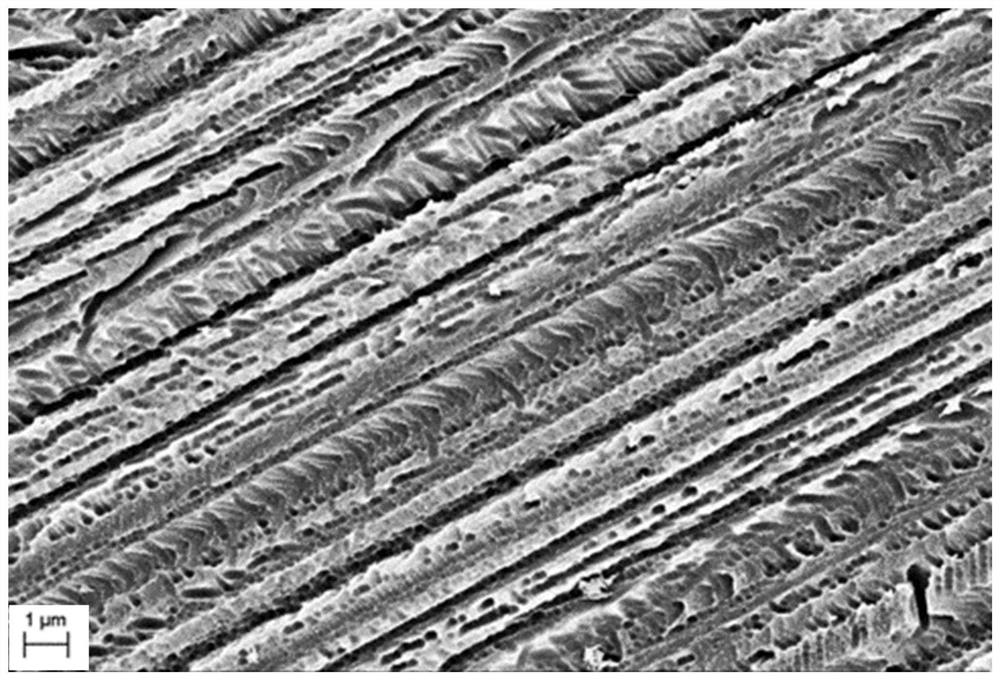

[0082] image 3 It is the scanning electron micrograph of the black silicon ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com