Kaolin product for catalytic cracking catalyst and preparation method thereof

A catalytic cracking and kaolin technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of small number of active centers, small specific surface area and pores of kaolin, limited ability to crack petroleum molecules, etc., to achieve The effect of expanding pores, improving pores, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] The preparation of chlorine dioxide microcapsules comprises the following steps:

[0054] S1. Configure 100ml of stable chlorine dioxide aqueous solution with a concentration of 37000mg / L, and obtain the chlorine dioxide core material after pressure filtration through a microporous membrane with a filtration accuracy of 0.5 μm;

[0055] S2. Dissolve 0.1 g of gelatin in the chlorine dioxide core material, and dissolve in a constant temperature water bath at 40°C for 60 minutes to obtain an aqueous phase solution, which is set aside;

[0056] S3, take 0.1g PLA and dissolve in 100ml of dichloromethane, stir for 120min under mechanical stirring condition, make it dissolve completely, obtain oil phase solution;

[0057] S4. Measure 30ml of the oil phase solution and place it on a mechanical stirrer to stir, add 0.3ml of Span 80 emulsifier while stirring, add 30ml of the water phase solution after stirring evenly, stir at 300r / min for 5min, then add 20ml of liquid paraffin A...

preparation example 2

[0059] The preparation of chlorine dioxide microcapsules comprises the following steps:

[0060] S1. Configure 100ml of stable chlorine dioxide aqueous solution with a concentration of 37000mg / L, and obtain the chlorine dioxide core material after pressure filtration through a microporous membrane with a filtration accuracy of 0.5 μm;

[0061] S2. Take 5g of gelatin and dissolve it in the chlorine dioxide core material, and dissolve it in a constant temperature water bath at 40°C for 60 minutes to obtain an aqueous phase solution, which is set aside;

[0062] S3. Dissolve 10 g of PLA in 100 ml of dichloromethane, and stir for 120 min under mechanical stirring to completely dissolve it to obtain an oil phase solution;

[0063] S4, measure 30ml of oil phase solution and place it on a mechanical stirrer to stir, add 3ml of Span 80 emulsifier while stirring, add 3ml of water phase solution after stirring evenly, after stirring at 1200r / min for 2min, then add 20ml of liquid paraffi...

preparation example 3

[0065] The preparation of chlorine dioxide microcapsules comprises the following steps:

[0066] S1. Configure 100ml of stable chlorine dioxide aqueous solution with a concentration of 37000mg / L, and obtain the chlorine dioxide core material after pressure filtration through a microporous membrane with a filtration accuracy of 0.5 μm;

[0067] S2. Take 10g of gelatin and dissolve it in the chlorine dioxide core material, and dissolve it in a constant temperature water bath at 40°C for 60 minutes to obtain an aqueous phase solution, which is set aside;

[0068] S3. Dissolve 20 g of PLA in 100 ml of dichloromethane, and stir for 120 min under mechanical stirring conditions to completely dissolve it to obtain an oil phase solution;

[0069] S4. Measure 30ml of oil phase solution and place it on a mechanical stirrer to stir, add 6ml of Span 80 emulsifier while stirring, add 1.5ml of water phase solution after stirring evenly, stir at 2000r / min for 3min, then add 20ml of liquid par...

PUM

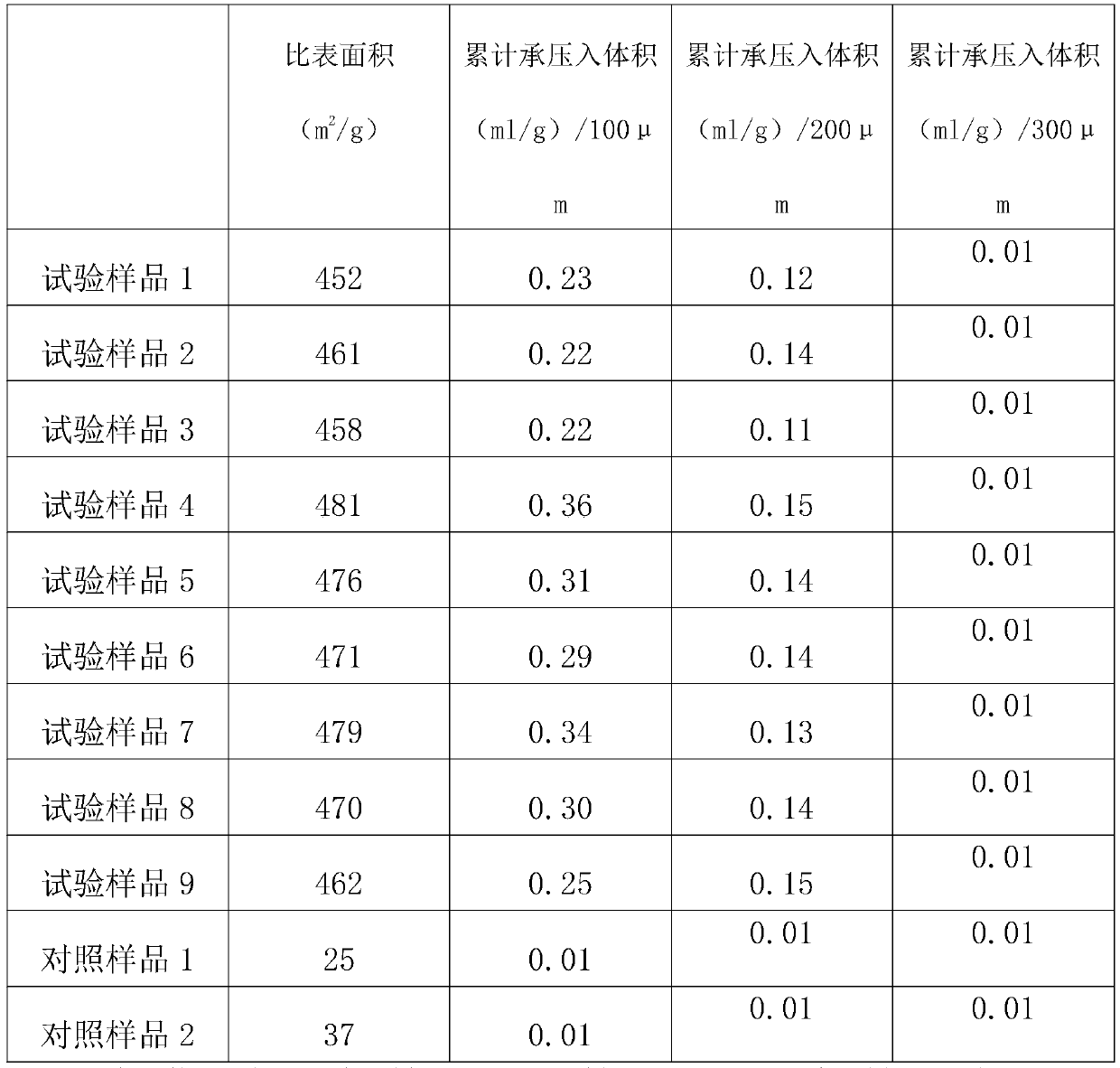

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com