Lithium battery manufacturing process

A manufacturing process, lithium battery technology, applied in the direction of sustainable manufacturing/processing, secondary battery, final product manufacturing, etc., can solve the problems of battery performance degradation, inability to completely remove battery core moisture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

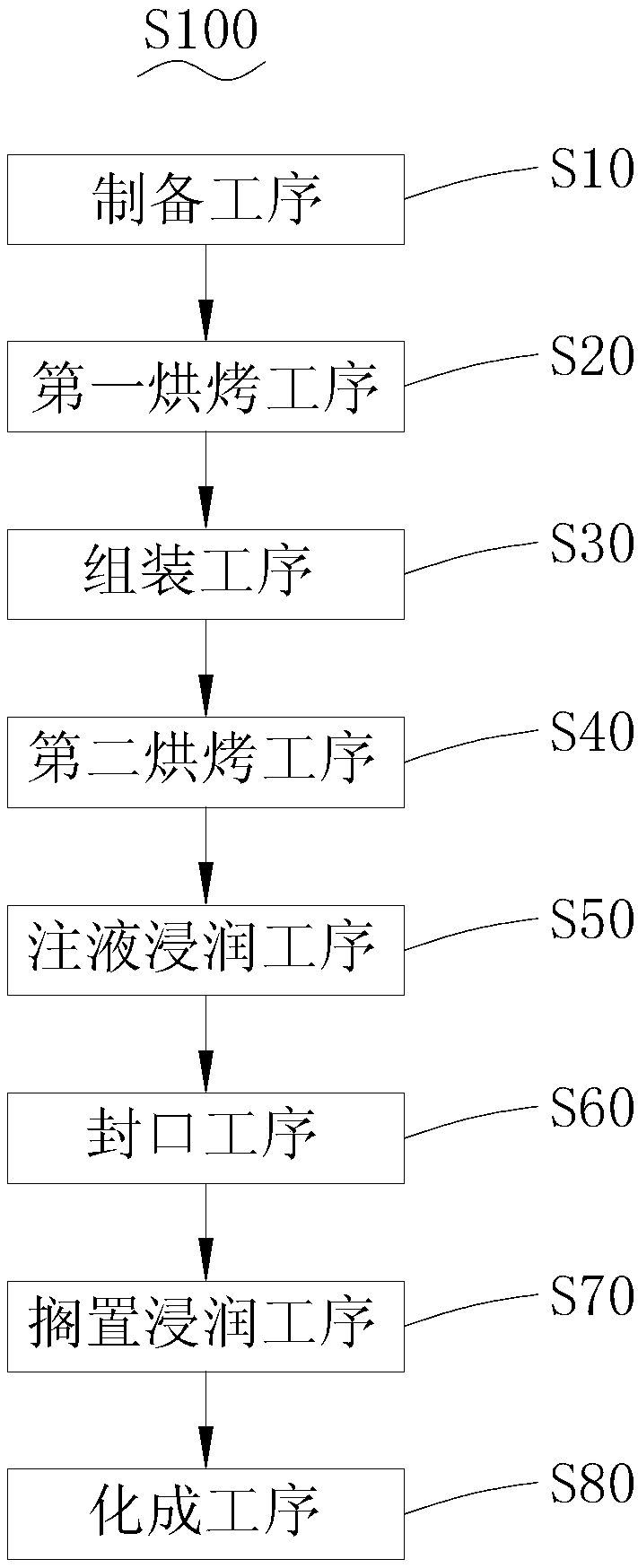

[0077] see figure 1 , Embodiment 1 of the present invention provides a lithium battery manufacturing process S100, including:

[0078] Preparation process S10, preparing pole pieces or winding cores;

[0079] The first baking process S20, putting the pole piece or the winding core into an oven for baking;

[0080] Assembling process S30, winding the pole piece after the first baking process into a winding core, and installing the winding core inside the battery case with an opening at one end to make a semi-finished battery, or, after the first baking process, The winding core in a baking process is installed inside the battery case with an open end to make a semi-finished battery;

[0081] The second baking process S40, putting the semi-finished battery that has completed the assembly process into an oven for baking;

[0082] Injection and wetting process S50, injecting an electrolyte solution into the semi-finished battery that has completed the second baking process to i...

Embodiment 2

[0134] The difference between this embodiment and Embodiment 1 is mainly that the material of the positive electrode coating is different, and the specific formation steps are also different, specifically reflected in: in this embodiment, the positive electrode coating includes a ternary material (nickel cobalt lithium manganese oxide) , the chemical conversion step S80 includes:

[0135] The first step is to charge the finished battery with a constant current of 0.2C, and during the charging process, set the upper limit of the charging voltage to 4200-4400mV, and the entire charging time is 120min;

[0136] The second sub-step is to charge the finished battery that has completed the first sub-step with a constant current of 0.3C, and set the upper limit of the charging voltage to 4200-4400mV during the charging process. When the charging voltage rises to the set value, Keep the charging voltage constant, then control the charging current to gradually drop to 0.01C, stop charg...

Embodiment 3

[0146] The difference between this embodiment and Embodiment 1 is mainly that the material of the positive electrode coating is different, and the specific formation steps are also different, specifically reflected in: in this embodiment, the positive electrode coating includes a ternary material (nickel cobalt lithium manganese oxide) , the chemical conversion step S80 includes:

[0147] The first sub-step is to charge the finished battery with a constant current of 0.02C, and during the charging process, set the charging upper limit voltage to 3850mV, and the entire charging time is 60min;

[0148] The second sub-step is to charge the finished battery after the first sub-step with a constant current of 0.1C, and during the charging process, set the charging upper limit voltage to 3850mV, and the entire charging time is 120min;

[0149] The third sub-step is to charge the finished battery after completing the second sub-step with a constant current of 0.2C, and during the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Exposed length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com