Preparation method of soft package battery

A soft-pack battery and cell technology, which is applied in secondary battery manufacturing, electrolyte battery manufacturing, secondary battery and other directions, can solve the problems of long preparation time and low production efficiency, achieve fast heat conduction, improve production efficiency, and improve production efficiency. Layer simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions and advantages of the present invention clearer, the present invention and its beneficial effects will be further described in detail below in conjunction with specific embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

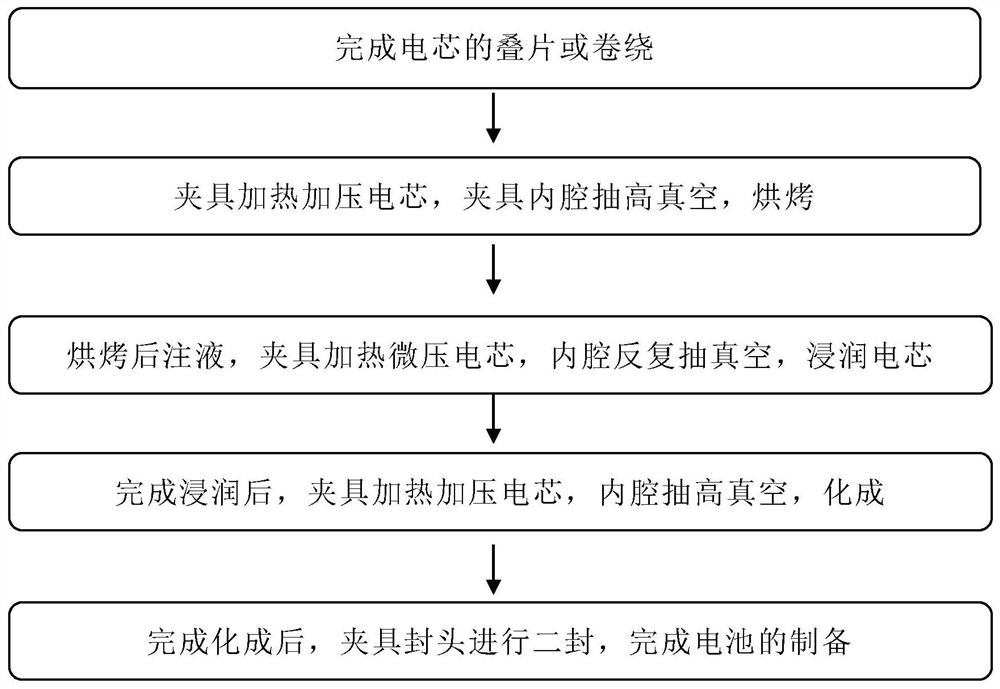

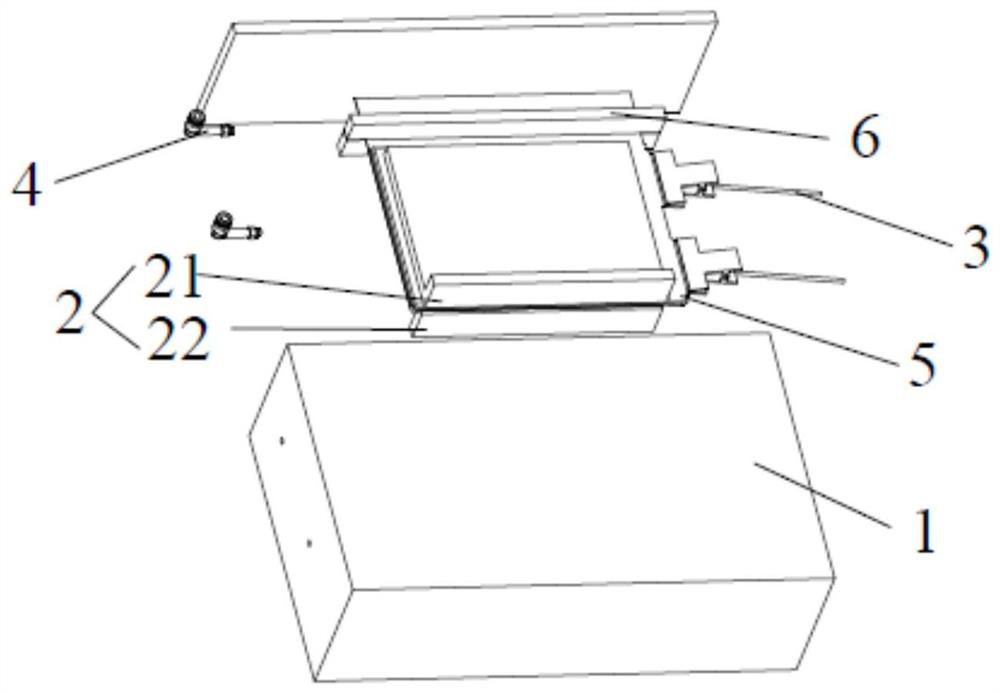

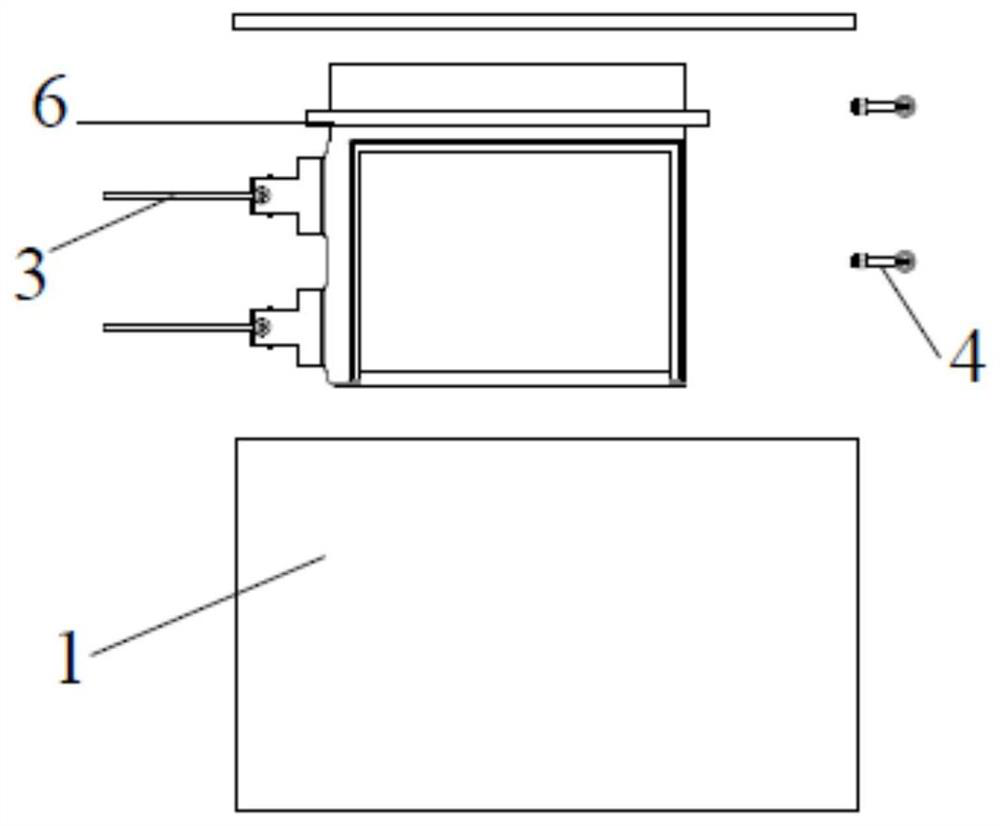

[0035] Such as Figure 1~3 Shown, a kind of preparation method of pouch battery, comprises the following steps:

[0036] Baking: Place the laminated or wound cells in the inner cavity of the jig, the jig clamps the cell and heats the cell, and at the same time evacuates the inner cavity of the jig to a high degree of vacuum; among them, the jig clamps the cell The pressure is 0.5 ~ 1MPa, which is beneficial to the heat transfer of the fixture during baking, and accelerates the evaporation of water in the battery cell; the pressure of high vacuum is -90 ~ -100KPa. In this vacuum state, the boiling point of water is significantly reduced. Quickly escape ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com