Cover for barrel roasting

A technology of barrel cans and domes, which is applied to casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of restricting heat transfer rate and dynamic heat loss of combustion, and achieves reduction of absorbed heat, lowering temperature, and improving The effect of baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

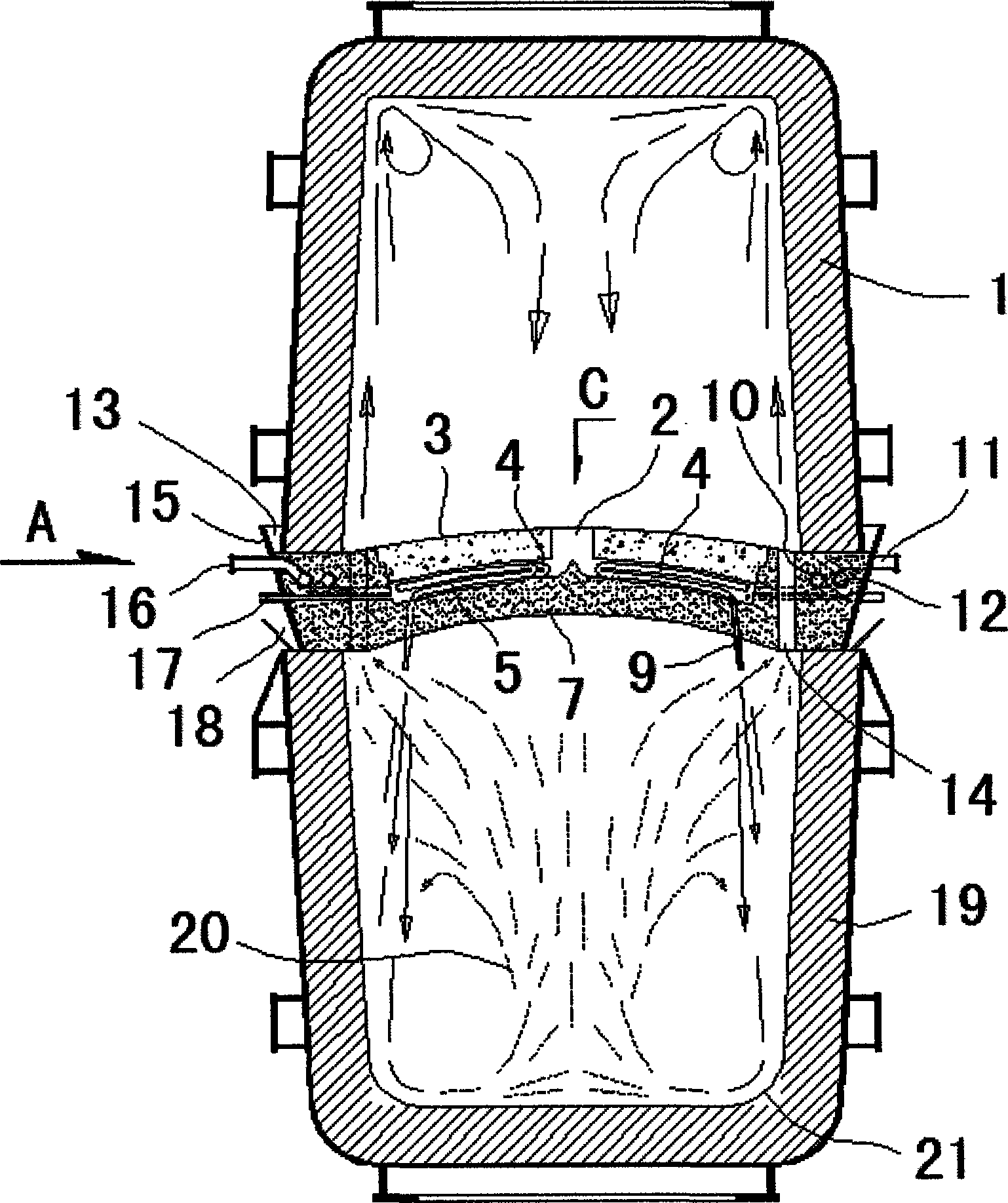

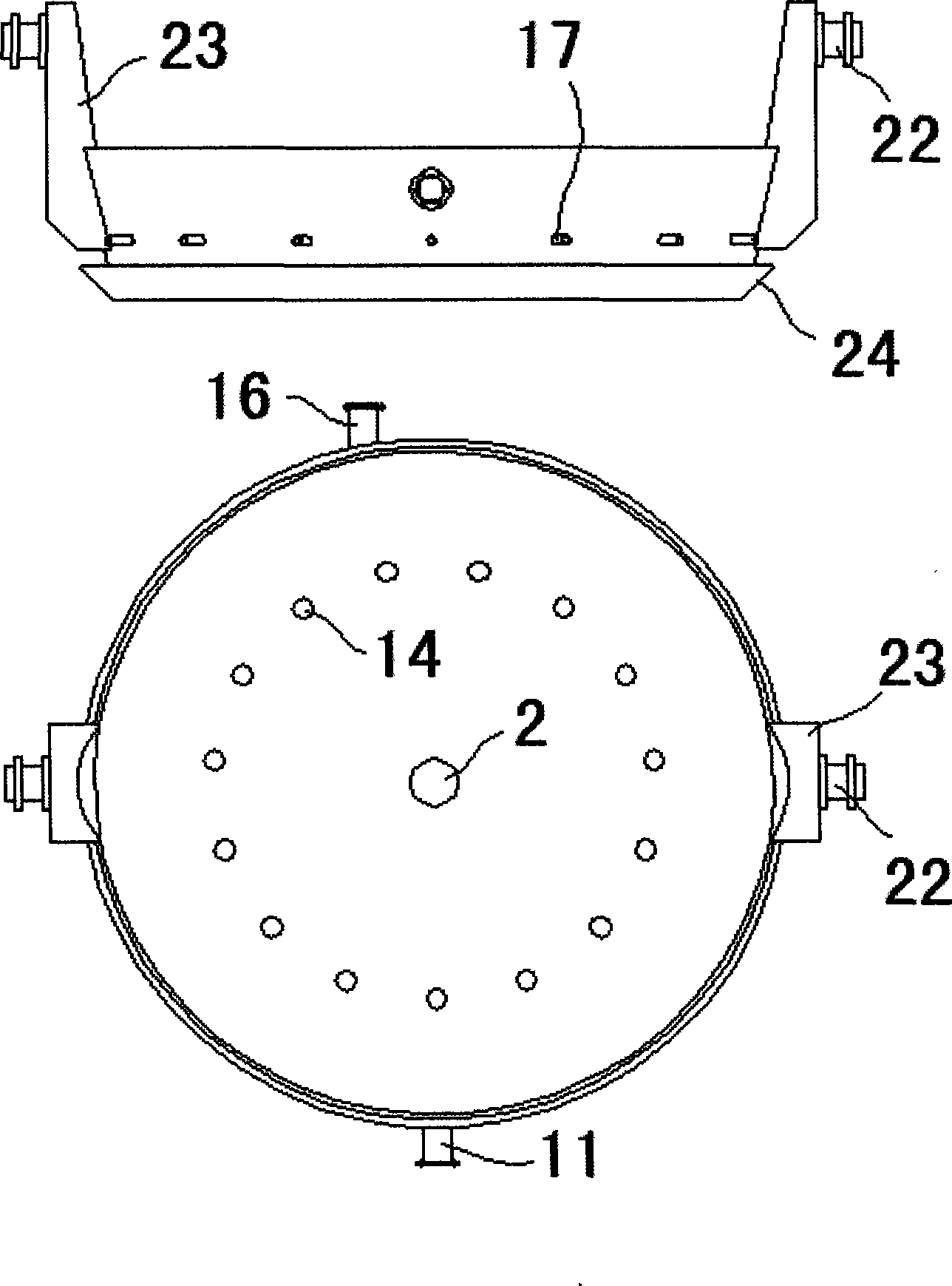

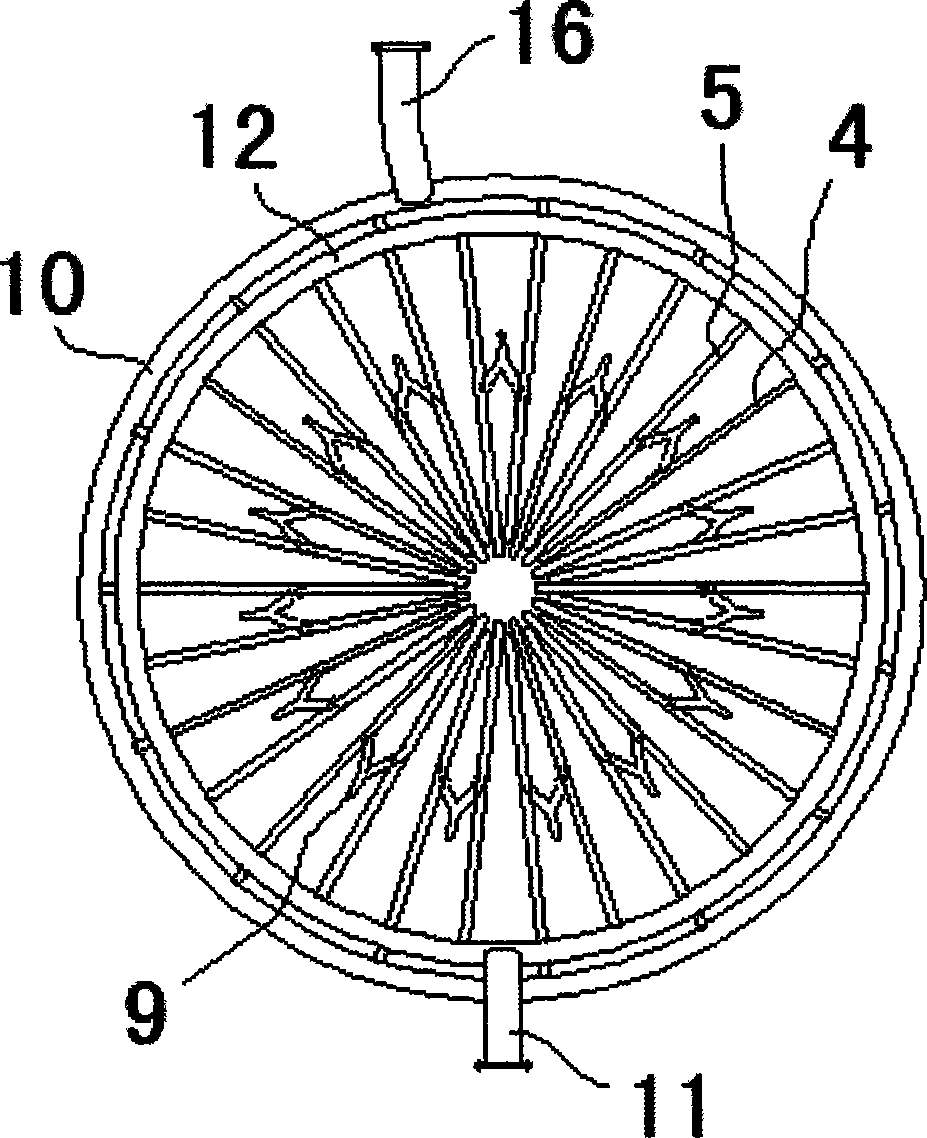

[0046] as attached Figure 1-3 As shown, the present embodiment is a lid for baking of barrels and cans, which includes: a lid body, the lid body is channeled and connected to the space in the two barrels, the lid body includes an arch hoop 15, and a bearing arranged in the arch hoop 15 A round arch 7, a round arch cover 3 is arranged on the round arch 7, an interlayer cavity is formed between the round arch 7 and the round arch cover 3, a baking and burning device is arranged in the interlayer cavity, and the center of the round arch cover 3 is formed There is a fire inlet 2, and the fire inlet 2 guides the flame heating and baking device, and the interlayer cavity communicates with the exhaust pipe 17 to guide and discharge the flame waste heat gas of the heating and baking device; A gas pipe 4 and the same number of air pipes 5, the tail section of multiple gas pipes 4 are fluidly connected to the gas distribution pipe 12, the gas distribution pipe 12 is connected to the ga...

Embodiment 2

[0049] as attached Figure 4-6 As shown in the example, the cover for baking cans described in this embodiment, the cover body also includes a partition wall ring 26, the partition wall ring 26 is connected to the arch shell cover 29, and the arch shell cover 29 is placed above the middle of the arch shell 8 A interlayer space is formed between the arch shell cover 29 and the arch shell 8, and an arch protrusion is formed above the middle of the arch shell 8, and the arch protrusion extends into the partition wall ring 26, and the gap between the arch protrusion and the arch shell cover 29 The interlayer is formed with a fire gap, the fire gap is connected to the interlayer cavity, the flame enters the interlayer cavity through the fire gap, the interlayer cavity is connected to the exhaust pipe 17, and the exhaust pipe 17 discharges the residual heat gas of the flame;

[0050] The interlayer space is provided with a preheating device, and the preheating device is a plurality ...

Embodiment 3

[0052] as attached Figure 7-14 as shown,

[0053] The cover body also has a fire-burning cover body and a fire-distributing cover body, the fire-burning cover body vault 33 is placed in the arch hoop 15, the vault bottom 37 is hung below the vault 33, and the vault bottom 37 is formed There is a fire inlet 38, and an interlayer cavity is formed between the vault bottom 37 and the vault 33. The interlayer cavity is arranged in a combustion device. The number of air heat exchange pipes 32, the tail section of the plurality of gas heat exchange pipes 36 are fluidly connected to the gas distribution pipe 12, the gas distribution pipe 12 is connected to the gas inlet 16, and the gas inlet 16 or enters carbon powder, and the plurality of air heat exchange pipes 32 The tail section is fluidly connected to the air distribution pipe 10, and the air distribution pipe 10 is formed with an air inlet 11, and the air inlet 11 or enters pure oxygen, and each gas heat exchange pipe 36 is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com