Water-based amino industrial coating and preparation method thereof

An amino and industrial technology, applied in the field of water-based amino industrial coatings, can solve the problems of not being able to meet the requirements of high-end products, difficult to apply to assembly line operations, poor water resistance and adhesion, and achieve excellent interlayer adhesion, good corrosion performance and Solvent resistance, reducing the effect of emulsifier impurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

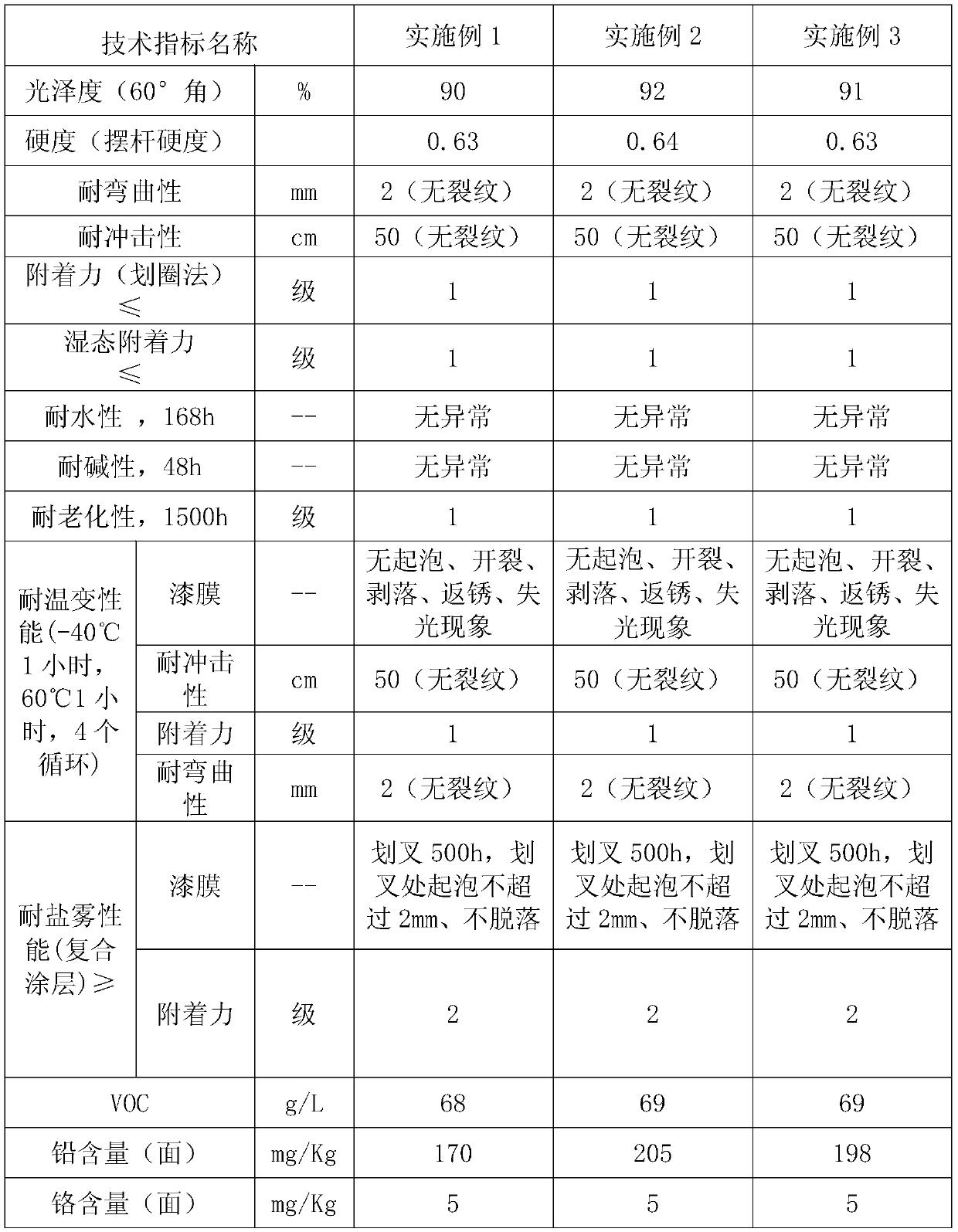

Examples

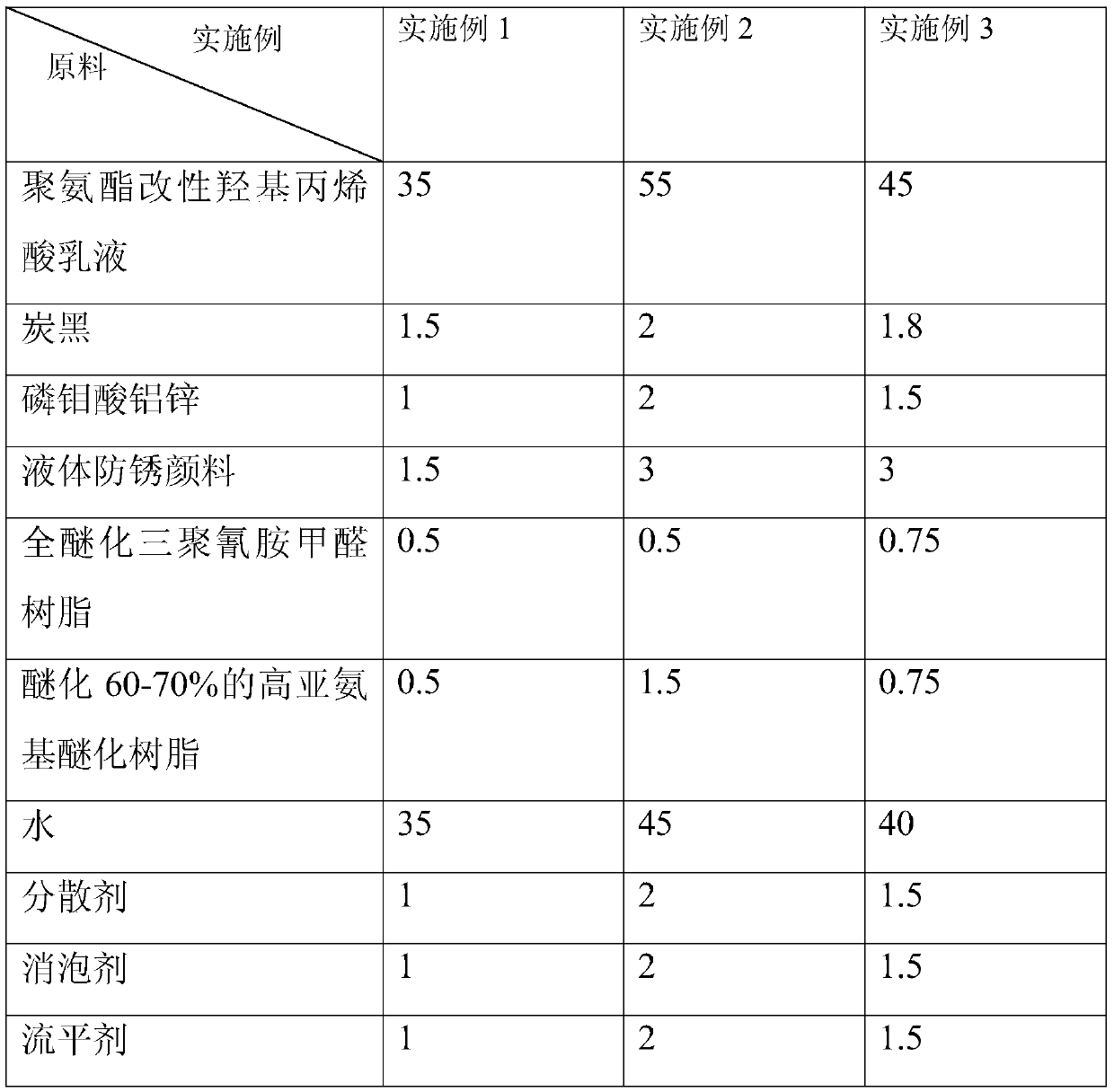

Embodiment 1-3

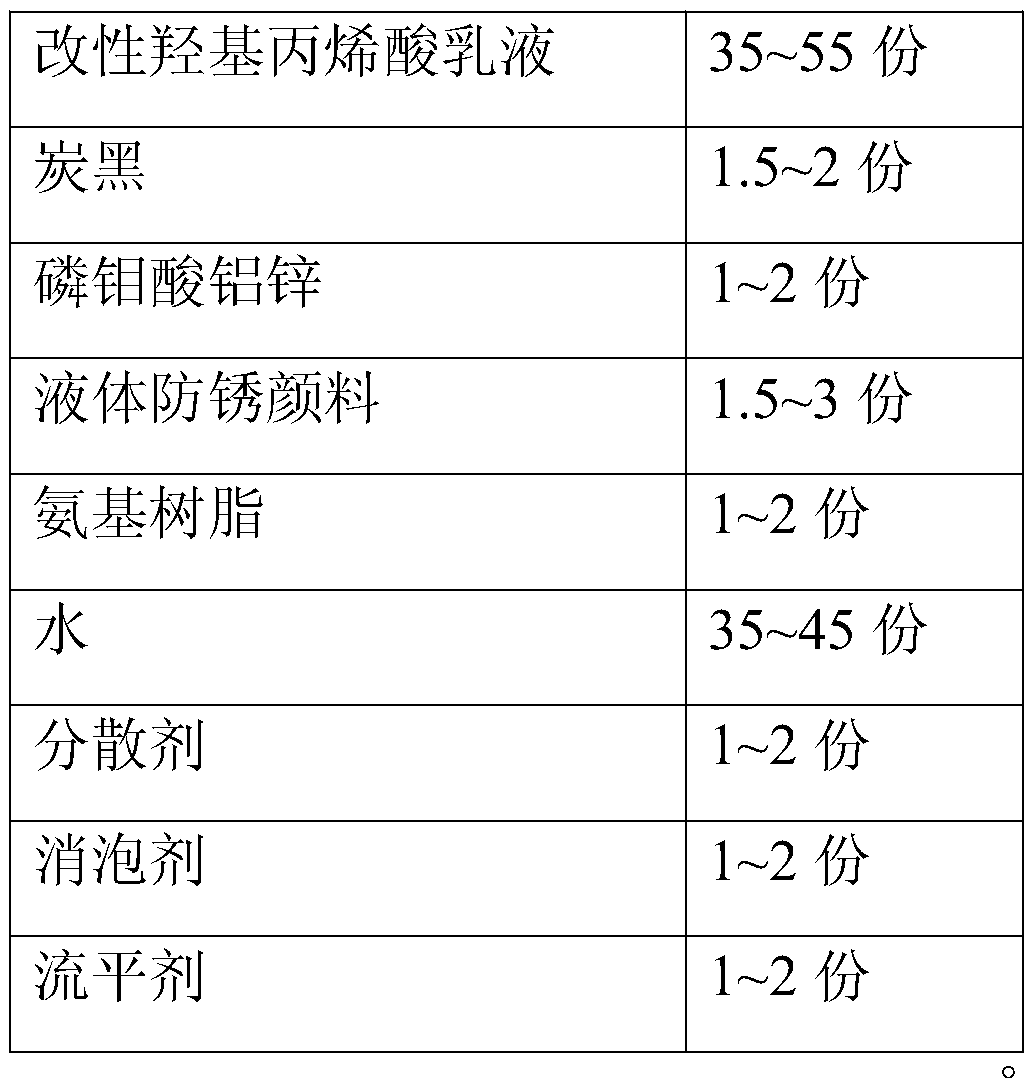

[0025] Adopt the formula composition shown in the table below to prepare water-based amino industrial coatings.

[0026]

[0027] Mix the modified hydroxyl acrylic emulsion with carbon black, aluminum zinc phosphomolybdate, fully etherified melamine formaldehyde resin, 60-70% etherified high imino etherified resin, water, dispersant, defoamer, fluid Put the leveling agent into the sand mill, grind it to below 20um, add the liquid anti-rust pigment under high-speed stirring, and mix evenly to get the water-based amino industrial coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com