A casting machine slag ditch baking device and baking method

A baking device and iron casting machine technology, which is applied in the field of metallurgical iron casting machine equipment, can solve the problems of fast cooling temperature of molten iron, low combustion efficiency, defire, etc., and achieve the effects of increasing the baking temperature, saving expenses, and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

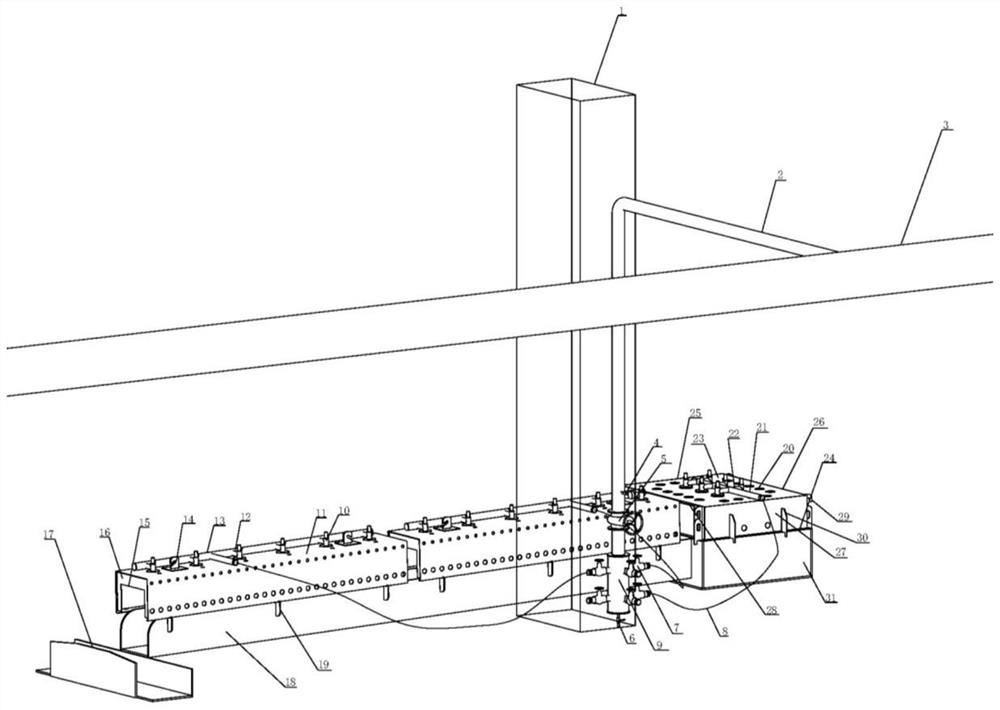

[0033]As shown in the figure, the cast iron machine slag ditch baking device includes a hollow long box preheating box with a concave cross section, and the preheating box is arranged above the molten iron ditch. There are 6 burners 10 on the central axis of the preheating box. The preheating box is formed by an outer preheating box 11, an inner preheating box 15 and an end plate 16 of the preheating box. The burners 10 run through the Preheating box to inner preheating box 15; Described outer preheating box 11 is provided with a plurality of air inlets 36 on the upper end face, side; The first air inlet 36-1 of the preheating box, the second air inlet 36-2 of the preheating box, and the third air inlet 36-3 of the preheating box arranged on the top of the outer preheating box close to the burner. The side wall of the iron gutter 18 is provided with an external preheating box positioning plate 19 ; the upper side of the external preheating box 11 is provided with a hook 14 . ...

Embodiment 2

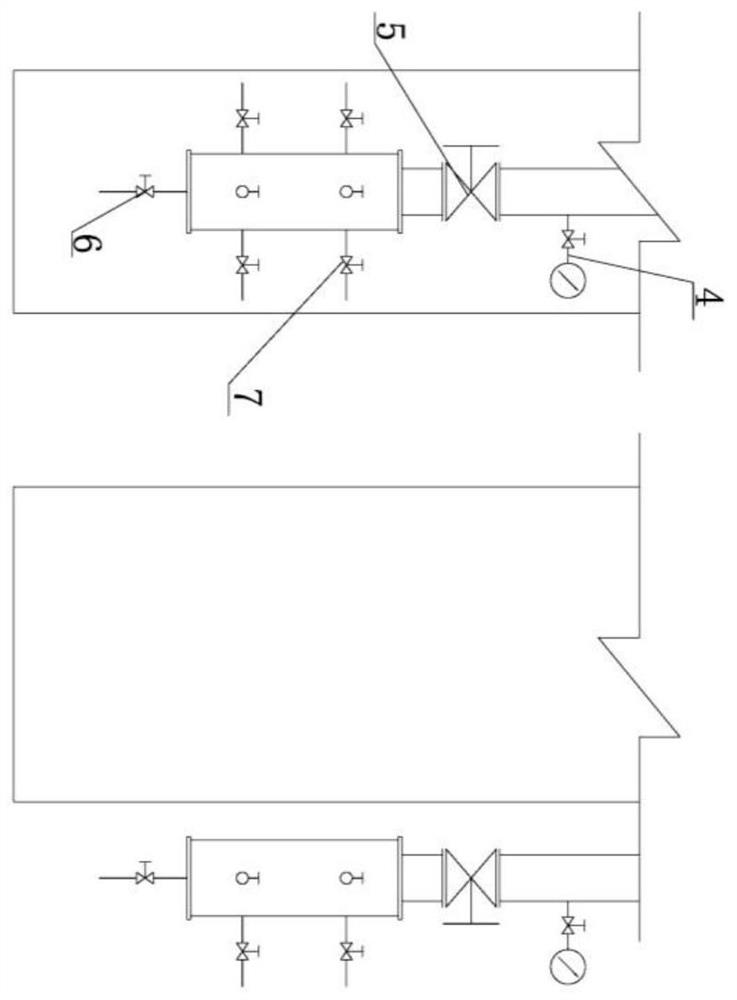

[0041] As shown in the figure, the cast iron machine slag ditch baking device includes a hollow square box, and the square box is composed of a square box upper plate 23, a square box lower plate 24, a square box side plate one 25, a square box side plate two 26, Square box side plate 3 27 and square box side plate 4 28 are enclosed and formed. There are 6 burners 10 evenly distributed in the middle of the square box. The burners 10 run through the square box to the square box lower plate 24 and the square box upper plate 23 A plurality of square box first air inlets 36-4 are evenly arranged around the burner 10; the square box side plate one 25 is provided with a square box first air vent 36-5; the square box side plate three 27 is provided with There is a second air vent 36-6 of the square box. In order to achieve the best air-fuel ratio, the burner 10 has the same structural requirements as the first embodiment. For the square box, the air intake data of the oven = ((the d...

Embodiment 3

[0044] A method for baking a cast iron machine slag ditch, comprising the steps of:

[0045] (1) Between the blast furnace molten iron and the chute 17, a refractory material frame 31 and an inclined molten iron ditch 18 are arranged in sequence, and a gas pipe 2 connected to the main gas pipe network 3 is arranged on the factory building column 1; the length of the molten iron ditch 18 is 6900 mm;

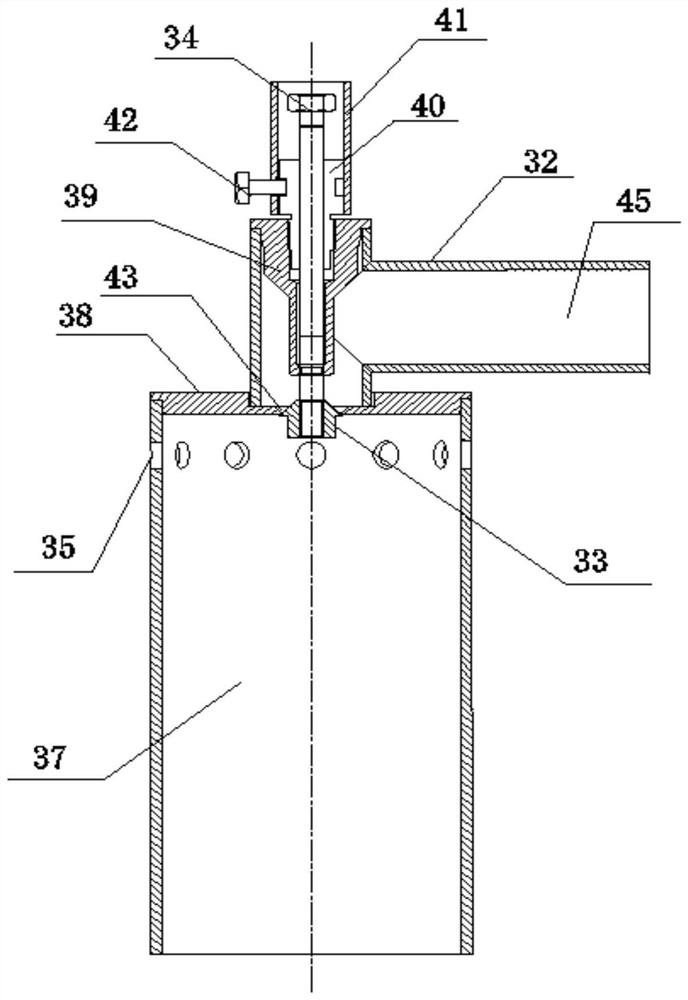

[0046] (2) The outer preheating box positioning plate 19 is arranged on the side wall of the molten iron ditch 18, and two long box preheating boxes described in Embodiment 1 are placed above the molten iron ditch 18 along the flowing direction of the molten iron, and the length of the long box preheating box is 3300mm, the diameter of the combustion tube 37 of the burner is 133mm, there are 12 automatic air induction holes 35, the diameter of which is 12mm, the bottom diameter of the jet port 43 is 25mm, and the top diameter is 31mm, in the preheating box, the automatic air induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com