Method for processing normal-temperature storage type roasted goose

A processing method and technology of roast goose, which is applied in the field of processing roast goose stored at room temperature, can solve the problems of affecting the product texture and taste, the degree of meat damage, and the separation of meat and bones of the product, so as to reduce the collapse and cell rupture and drying time The effect of shortening and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

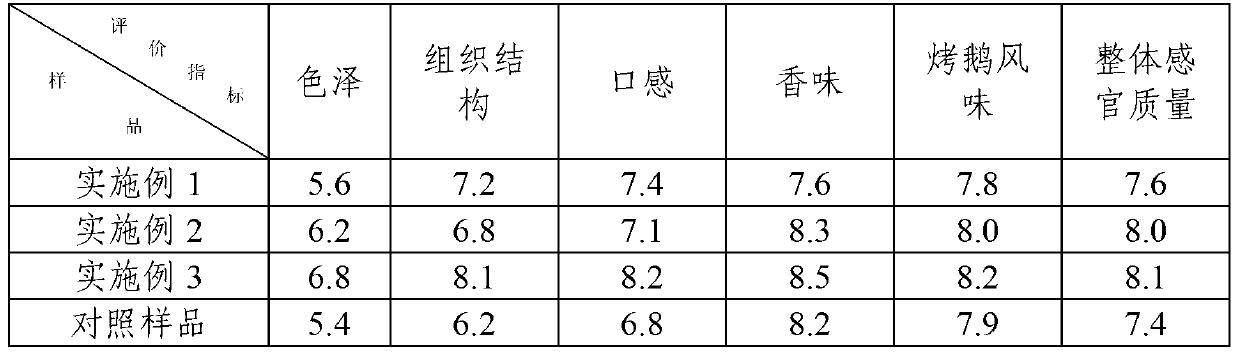

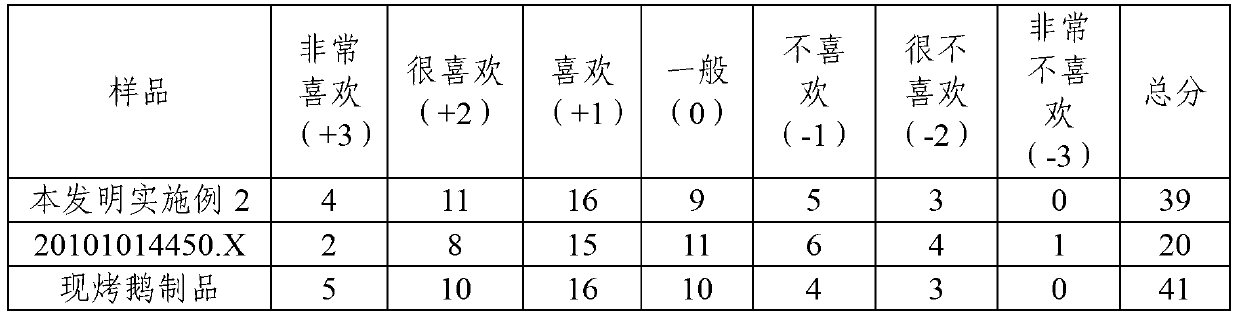

Examples

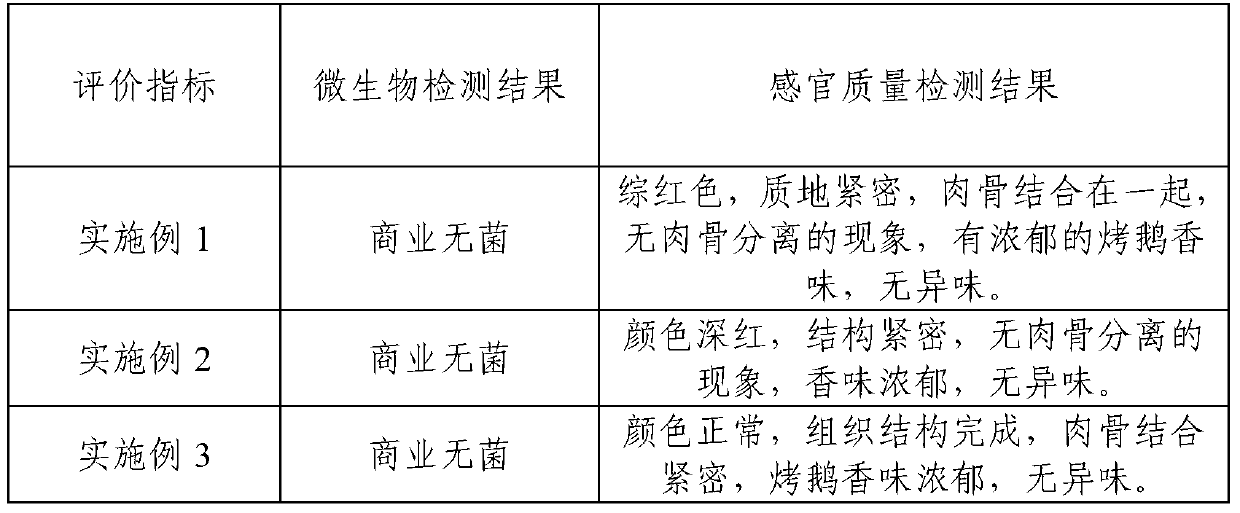

Embodiment 1

[0041] 1. Preparation of spice liquid

[0042] (1) For every 100 parts by mass of spice liquid, use the following raw materials by mass: 0.5 parts star anise, 0.2 parts cinnamon, 0.1 parts cloves, 0.1 parts Kaempferia, 0.1 parts grass fruit, 0.2 parts bay leaf, 0.3 parts cassia bark, 0.2 parts tangerine peel 0.5 parts of fresh ginger and 5 parts of goose bones;

[0043] (2) Wrap the above-mentioned raw materials with medical gauze, put them into weighed water and boil them over high heat, then boil them at a temperature of 90°C for 2 hours, and cool them down to obtain the spice liquid.

[0044] 2. Treatment of goose carcass

[0045] Purchase 4 Mayang white geese from the farmers’ market in Mayang County, slaughter them, bled them, and eviscerated them to obtain the goose carcasses or thawed goose carcasses, remove the goose feet and wings, cut them longitudinally from the belly of the goose, and remove all The internal organs, and the total weight of the goose carcass after...

Embodiment 2

[0067] 1. Preparation of spice liquid

[0068] (1) For every 100 parts by mass of spice liquid, use the following raw materials by mass: 0.5 parts star anise, 0.2 parts cinnamon, 0.1 parts cloves, 0.1 parts Kaempferia, 0.1 parts grass fruit, 0.2 parts bay leaf, 0.3 parts cassia bark, 0.2 parts tangerine peel 0.5 parts of fresh ginger and 4 parts of goose bones;

[0069] (2) Wrap the above-mentioned raw materials with medical gauze, put them into weighed water and boil them over high heat, then boil them at a temperature of 85°C for 2.5 hours, and cool them down to obtain the spice liquid.

[0070] 2. Treatment of goose carcass

[0071] In this experiment, the purchased frozen goose was selected from Shandong. After the thawed carcass of the goose was removed from the goose paws and wings, the goose was cut longitudinally from the abdomen to remove all internal organs, and rinsed with clean water for later use;

[0072] 3. Marinated goose

[0073] (1) The formula of pickling...

Embodiment 3

[0093] 1. Preparation of spice liquid

[0094] (1) For every 100 parts by mass of spice liquid, use the following raw materials by mass: 0.5 parts star anise, 0.2 parts cinnamon, 0.1 parts cloves, 0.1 parts Kaempferia, 0.1 parts grass fruit, 0.2 parts bay leaf, 0.3 parts cassia bark, 0.2 parts tangerine peel 0.5 parts of fresh ginger and 3 parts of goose bones;

[0095] (2) Wrap the above-mentioned raw materials with medical gauze, put them into weighed water and boil over high heat, then extract at a temperature of 80°C for 3 hours, and cool to obtain the spice liquid.

[0096] 2. Treatment of goose carcass

[0097] After slaughtering, bleeding and evisceration, the carcass of the goose is cooled to 4°C, then the feet and wings of the goose are removed, and the belly of the goose is cut longitudinally, all internal organs are removed, and rinsed with clean water for use;

[0098] 3. Marinated goose

[0099] (1) The formula of pickling preparation: 4 kg of salt for every 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com