Charcoal-burning tank roasting device

A technology of coal and filling, applied in the field of baking and coking, can solve the problem that the barrel body cannot be fully utilized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

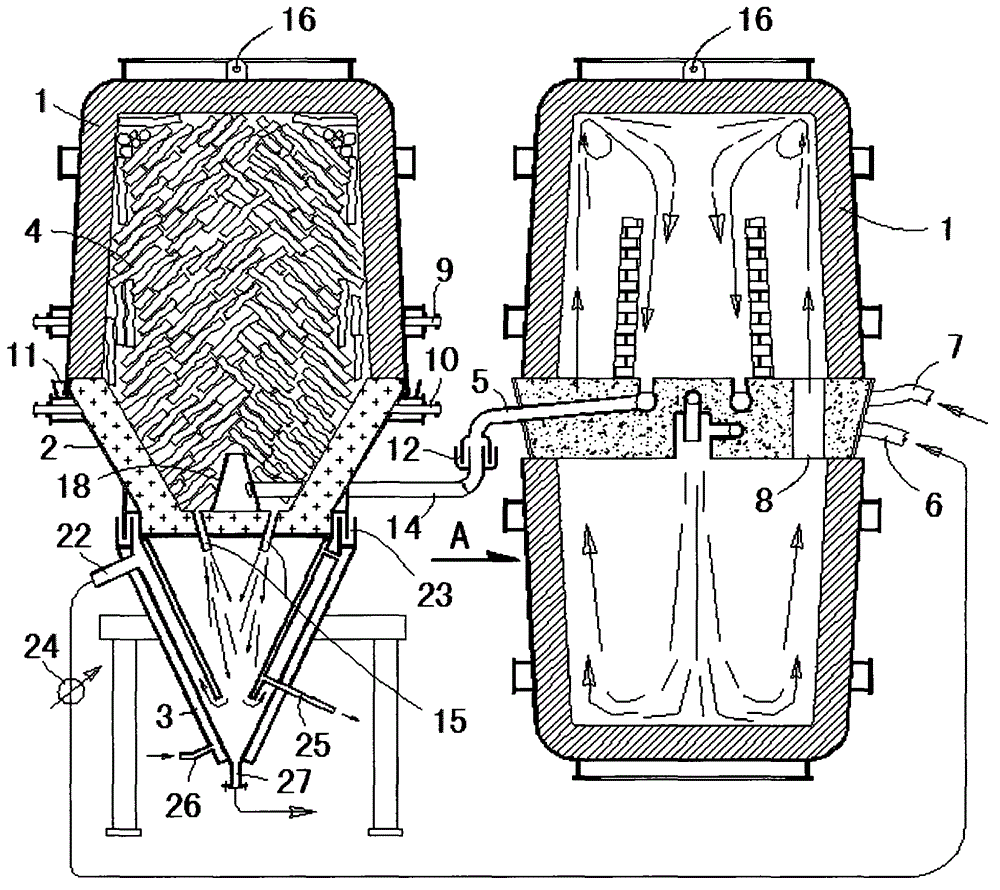

[0031] as attached Figure 1-3 as shown,

[0032] A kind of charcoal-fired baking tank device described in this embodiment,

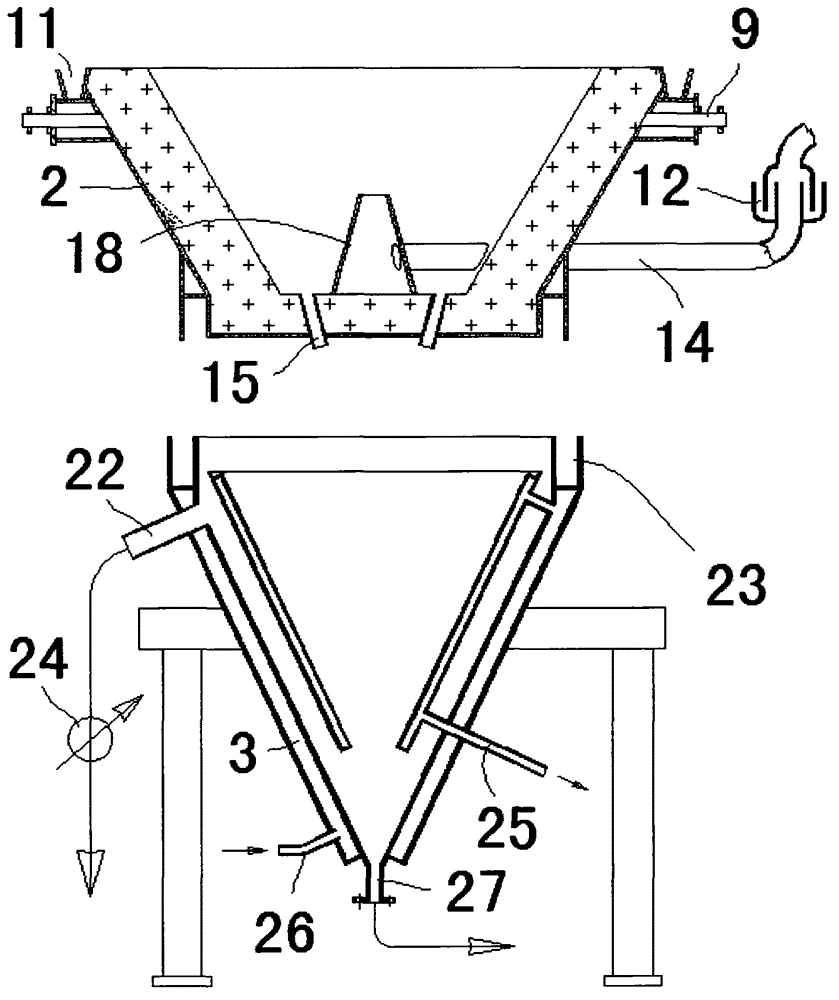

[0033] It has a body, including: a tank 1, a cone bottom 2, and a water-cooling cone 3.

[0034] The tank 1 filled with coal 4 is buckled on the tank sand seal 11 of the cone bottom 2, and the cone bottom 2 is seated on the bottom sand seal 23 of the water-cooled cone 3. The bottom ring of the cone bottom 2 is provided with a plurality of bottom pipes 15, and the bottom A flue gas port 18 is placed in the middle of the pipe 15, and the flue gas port 18 is connected to the smoke receiving pipe 14, and the smoke receiving pipe 14 is connected to the smoke exhaust pipe 5 of the oven lid through the smoke pipe sand seal 12, and the hot flue gas of the oven passes through the smoke exhaust pipe 5 , the smoke pipe sand seal 12, the smoke receiving pipe 14 is upwardly heated by the flue gas port 18 to heat the charcoal 4 dry distillation forming carbon, the ...

Embodiment 2

[0038] Such as Figure 4-6 As shown, the baking lid of the tank 1 is provided with a baking furnace 21, and the baking furnace 21 is provided with a furnace cover 17. Below the hearth 13 is an arc-shaped ramp 20, which is connected to the fire mouth 19, and the coal Combustion in the arc-shaped ramp 20, the compressor 28 supplies the preheating air pipe 7 to preheat the combustion-supporting air to assist the coal combustion, or the steam and the combustion-supporting air are mixed to assist the coal combustion, and the ashes of the coal combustion are pushed to the fire chute 19 by the continuously sliding coal. Fall into the bottom of the tank 1 by the fire chute 19, and the burning flame rises to the position of the preheating air pipe 7 through the fire channel 8 to heat the preheating air pipe 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com