Bread machine capable of manufacturing baguette and manufacturing method of baguette

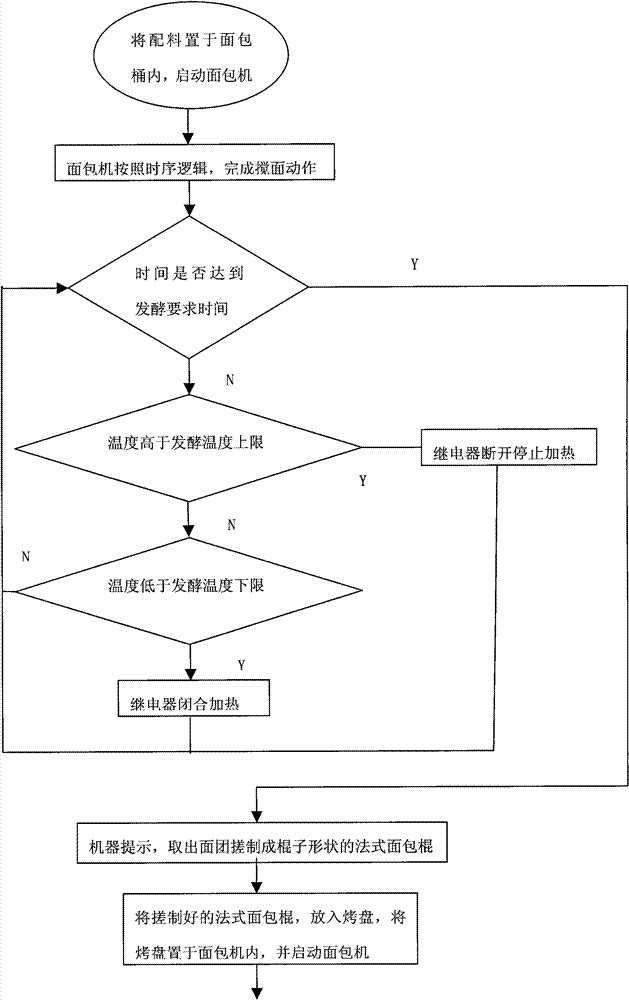

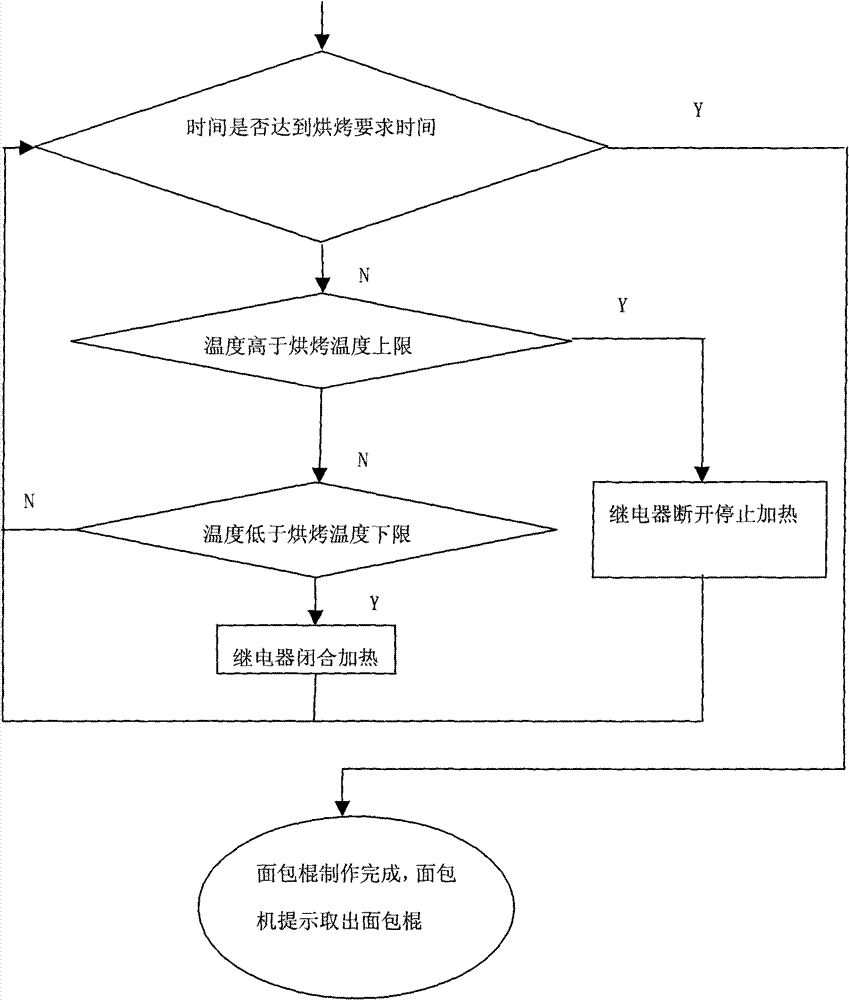

A production method and technology of a bread machine, applied in the field of food manufacturing, can solve the problems of inability to bake a baguette, low baking temperature, and inability to take out the baguette, so as to reduce labor intensity, simplify the production process, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

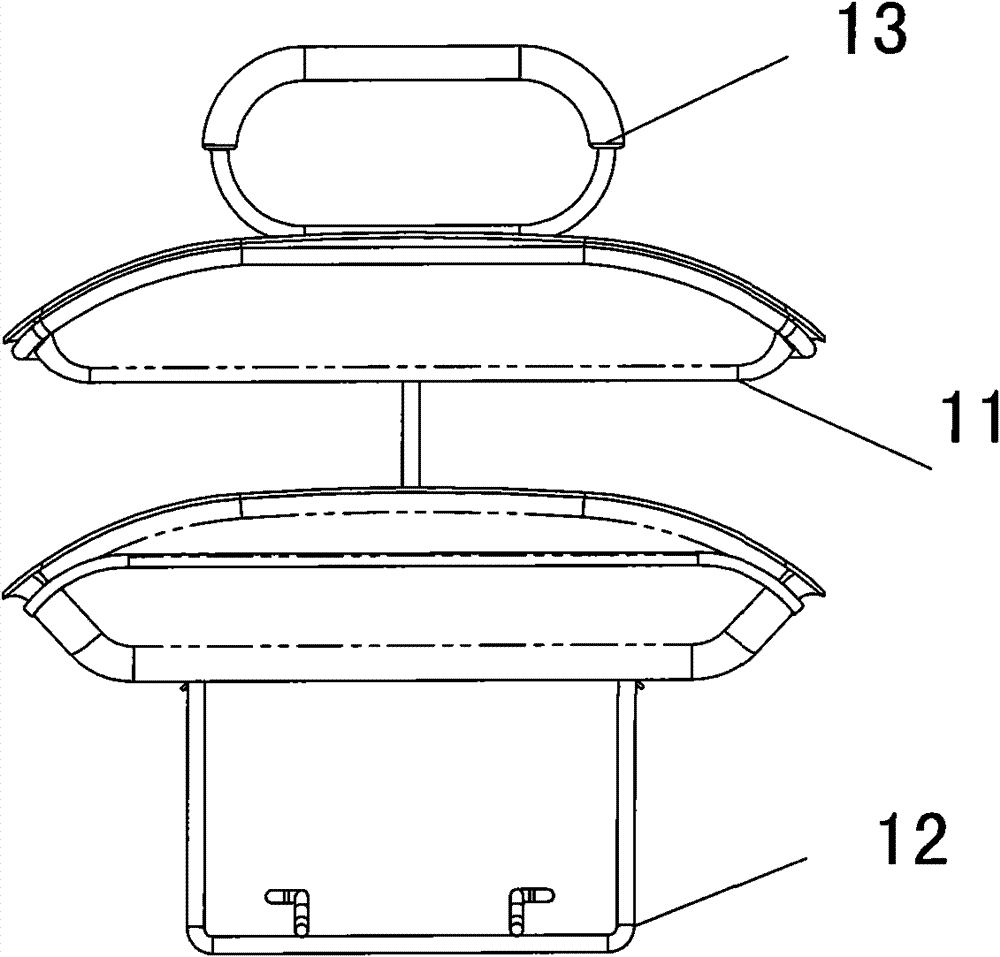

[0022] The invention discloses a bread machine capable of making French bread sticks, such as figure 2 , 3 , 4, 5, 6, 7, including an outer casing 4, an oven 6 located in the outer casing 4, an upper cover 7 installed on the top of the outer casing 1; the outer casing 1 is provided with a control panel 5; The upper cover 7, the oven 6, and the outer shell 4 surround a closed manufacturing cavity; a heating element is arranged in the manufacturing cavity of the bread machine; wherein: a bakeable French bread is also arranged in the manufacturing cavity of the bread machine The baking pan assembly 1, the baking pan assembly 1 includes: more than one baking pan 11 and a bracket 12 for fixing the baking pan 11; the bracket 12 is fixed on the oven 6, and the baking pan 11 rests on the On the bracket 12; the control panel 5 is provided with a control device for making French bread sticks.

[0023] The cross-section of the baking pan 11 is a trapezoidal shape with an upper opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com