Internal combustion blast furnace gas special nozzle with pyramid trustum jet device

A technology of blast furnace gas with edge, which is applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems that blast furnace gas is difficult to ignite, easy to break and extinguish, etc., so as to reduce equipment investment, increase baking temperature, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

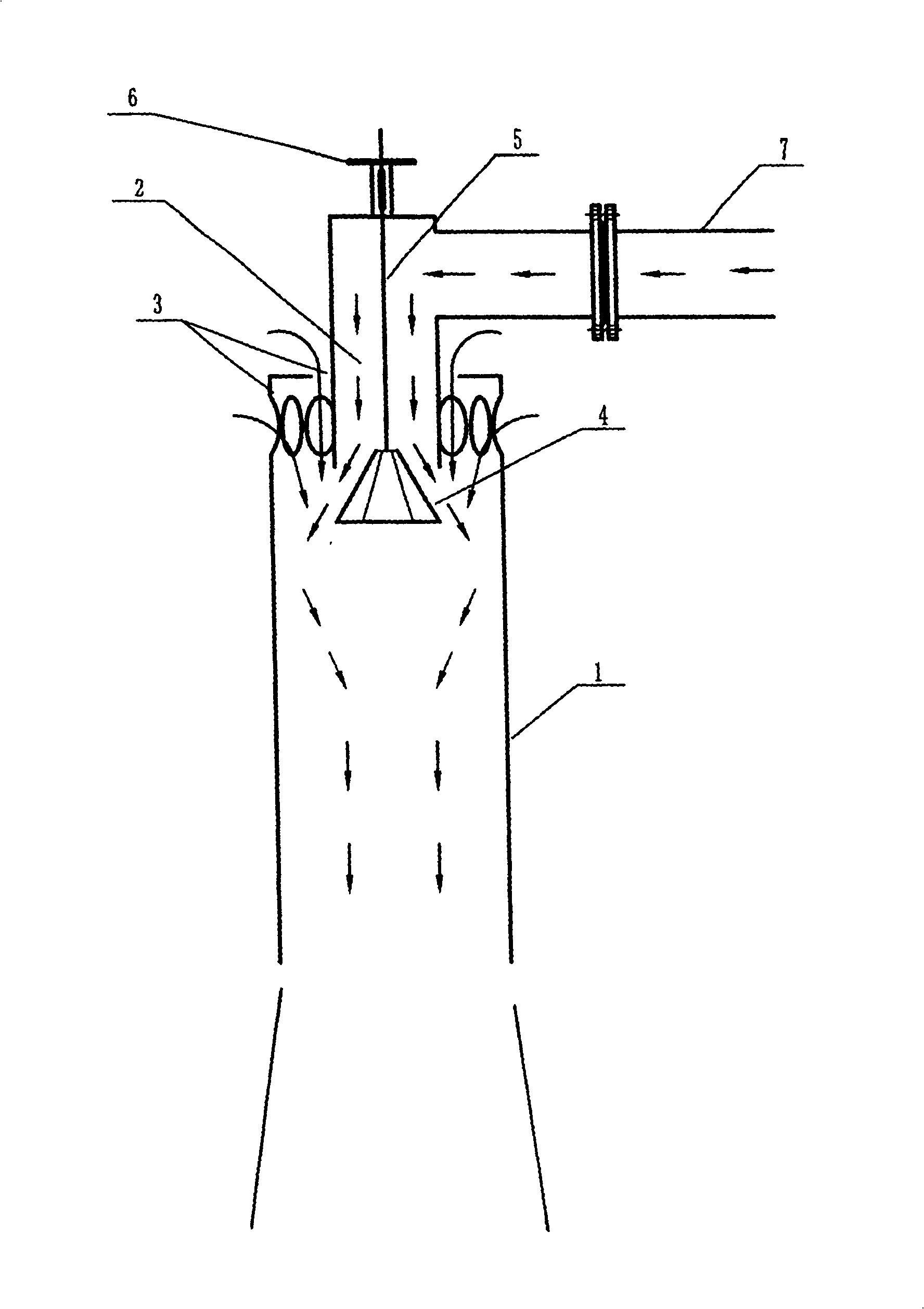

[0021] In Fig. 1, the blast furnace gas pipeline 1 is connected with one end of the nozzle 2, and the other end of the nozzle 2 is placed at one end of the combustion tube 1, and the other end is the outlet of the flame. The nozzle 2 has a built-in prism body jet device matching its shape, which includes a prism body diameter adjustment valve 4, which is connected to the diameter adjustment valve joystick 5, and the top end of the diameter adjustment valve joystick 5 is connected to the diameter adjustment valve handwheel 6. By turning the diameter-adjusting valve handwheel 6, the truss body diameter-adjusting valve 4 can be lifted or lowered, thereby controlling the airflow ejected from the nozzle 2, so that it can be kept in an ideal closed prism body air curtain.

[0022] In order to ensure sufficient mixing of gas and combustion-supporting air, several air holes 3 are arranged along the circumference on the peripheral wall corresponding to the position of the combustion tub...

Embodiment 2

[0024] In this embodiment, different from the first embodiment, there are several air holes 3 , which are arranged on the circumferential wall corresponding to the position of the nozzle 2 .

Embodiment 3

[0026] In this embodiment, different from the first embodiment, the air hole 3 is a gap between the combustion tube 1 and the nozzle 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com