Manufacturing method and production line of tempered vacuum glass

A technology of vacuum glass and its production method, which is applied in the production of tempered vacuum glass and the field of tempered vacuum glass production line, which can solve the problems of poor performance of vacuum glass, high welding temperature of glass solder, long welding time, etc., and reduce the heating temperature and heating time , Reduce the temperature of the edge banding, the effect of short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

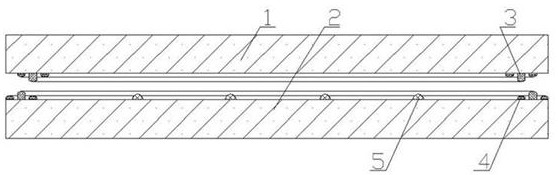

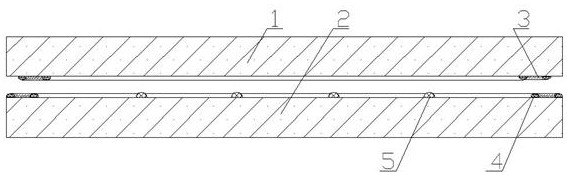

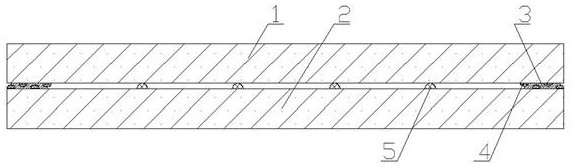

[0093] see figure 1 , figure 2 and image 3 , the vacuum glass is made up of upper glass 1 and lower glass 2, and its production method is as follows: first cut two flat glasses of required size according to the shape and size of the vacuum glass produced, and carry out edge grinding, chamfering, cleaning and drying; Next, on the upper glass 1, prepare the support 5 with a glass glaze and a glue dispenser, apply a glass solder 3 evenly with a glue dispenser on the periphery of the sealing surface of the two pieces of glass, and use a glass solder 3 on both sides of the glass solder 3 respectively. Glass frit and dispensing machine to prepare two spacers 4; the support 5 is distributed in a lattice whose smallest unit is an equilateral triangle, and the side length of the triangle is 40-50mm. After sintering and curing, the support 5 is approximately hemispherical and its diameter is about 0.6mm; the width of the glass solder 3 is about 2mm, the height is about 2mm, after th...

Embodiment 2

[0095] see Figure 4 , vacuum glass is composed of upper glass 1 and lower glass 2, and its production method is as follows: various equipment are connected into a continuous automatic production line, firstly, the cutting machine cuts two flat plates of required size according to the shape and size of the vacuum glass to be produced Glass, followed by edging machine for edging and chamfering, washing machine for cleaning and drying; thirdly, a dispensing machine applies a glass solder 3 and two spacers 4 on the upper glass 1, and coats the lower glass 2 Two glass solders 3 and three spacers 4; the width of each glass solder 3 is about 3 mm, and the height is about 2 mm. After sintering and solidification, each spacer 4 has a width of about 1.5 mm and a height of about 0.5 mm. The distance between the centers of two adjacent spacers 4 is about 6 mm; then the two pieces of glass enter the drying furnace for drying, and after drying, the two pieces of glass enter the tempering f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com