Bar-frame and groove sealed vacuum glass insulation panel and preparation method thereof

A technology of vacuum glass and thermal insulation panels, which is applied in glass manufacturing equipment, glass production, glass molding, etc., and can solve the problems of poor thermal insulation performance of external walls and insulation materials that cannot be used alone for external walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

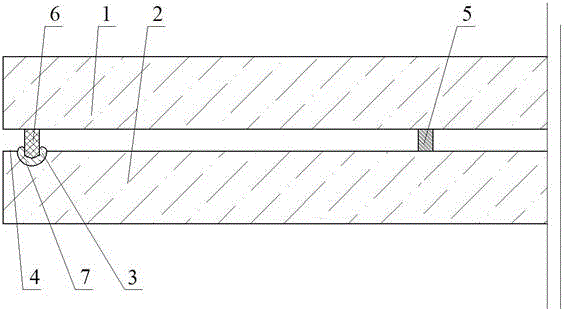

[0074] Example 1: see figure 1 , A vacuum glass insulation board with a frame and a groove sealed, two pieces of glass are tempered glass, one of which is low-e glass, the production method is as follows: First, cut the required size according to the shape and size of the vacuum glass insulation board made A piece of flat glass and a piece of low-emissivity glass, and an edge sealing groove 7 is opened on the lower glass 2, and then edging, chamfering, cleaning and drying are carried out; secondly, tempered glass ink and dispensing mechanism are used on the upper glass 1. Prepare the edge banding frame 6. On the upper glass 1, the support 5 is prepared by tempered glass ink and a dispenser. The support 5 is cylindrical, and then the two pieces of glass are sent to the tempering furnace for tempering treatment, and the prepared seal The side frame 6 and the support 5 are also sintered on the glass; the sintered support 5 is mechanically ground again to make the top in a plane, an...

Embodiment 2

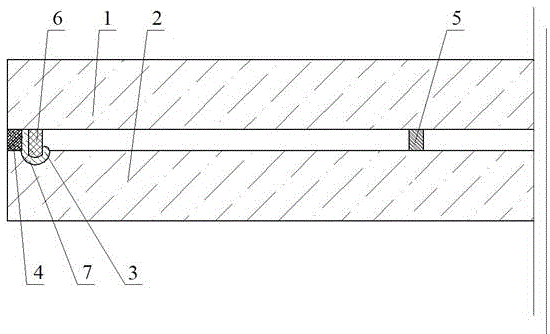

[0077] Example 2: see figure 2 , A two-layer sealed flat vacuum glass insulation board with edge-banding frame and edge-sealing groove. The two glasses are tempered glass, and one of them is low-e glass. The manufacturing method is as follows: First of all, according to the vacuum glass made The shape and size of the heat-insulating board cut a piece of flat glass and a piece of low-e glass of the required size, and open an edge sealing groove 7 on the lower glass 2, and then perform edge grinding, chamfering, cleaning and drying; secondly, the upper glass 1. Prepare the edge band frame 6 with tempered glass ink and glue machine respectively. The edge band frame 6 corresponds to the edge band groove 7. Then the two pieces of glass are sent into the tempering furnace for tempering treatment. The edge banding frame 6 is also sintered on the upper glass 1; again, the support 5 is prepared by polyimide adhesive and a dispenser. The support 5 is cylindrical, and the periphery of a p...

Embodiment 3

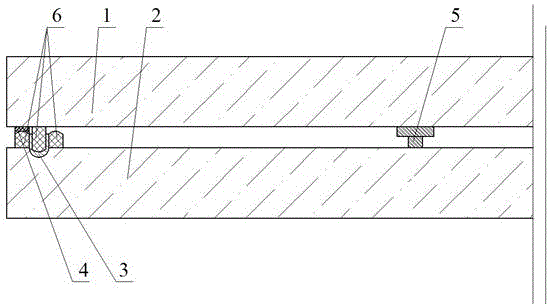

[0079] Example 3: See image 3 , A kind of two sealed flat vacuum glass insulation panels with edge bands on the upper and lower glass. The two glasses are tempered glass, and one of them is low-e glass. The manufacturing method is as follows: First, according to the vacuum glass insulation panel made Cut a piece of plate glass and a piece of low-e glass of the required size in shape and size, and open an edge sealing groove 7 on the lower glass 2, and then perform edge grinding, chamfering, cleaning and drying; secondly, the upper glass 1 and the lower glass 2. Use tempered glass ink and glue machine to prepare one and two edge banding frames 6. The edge banding frame 6 of the upper glass 1 corresponds to between the two edge banding frames 6 of the lower glass 2 and the lower glass 2. The two edge-banding frames are located on both sides of the edge-sealing groove 7, and then the two pieces of glass are respectively sent into the tempering furnace for tempering treatment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com