Patents

Literature

66results about How to "Maintain tempered properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

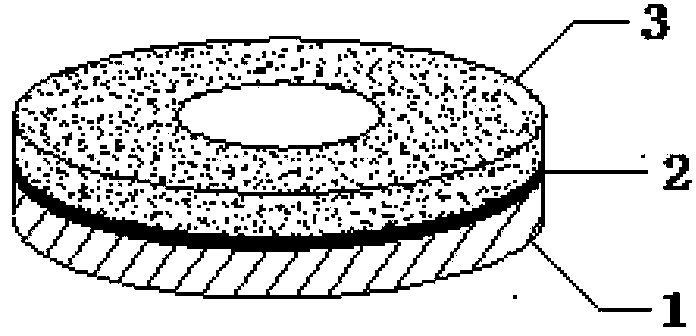

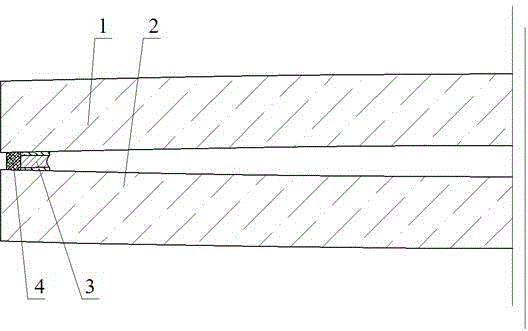

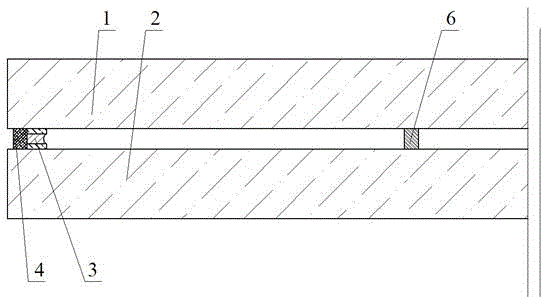

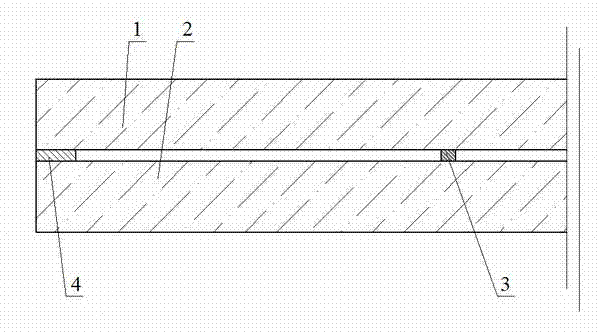

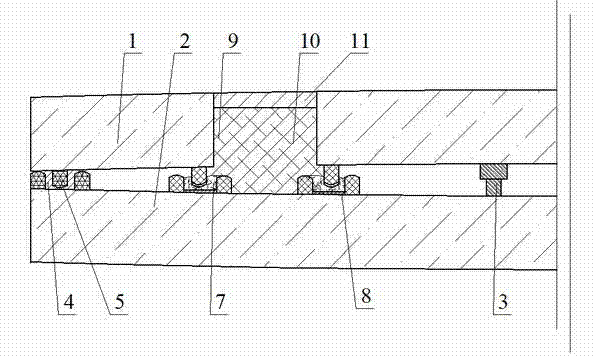

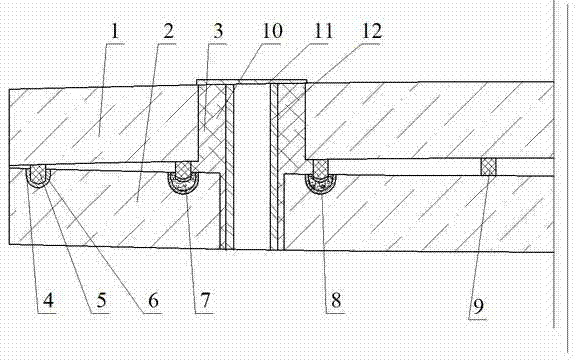

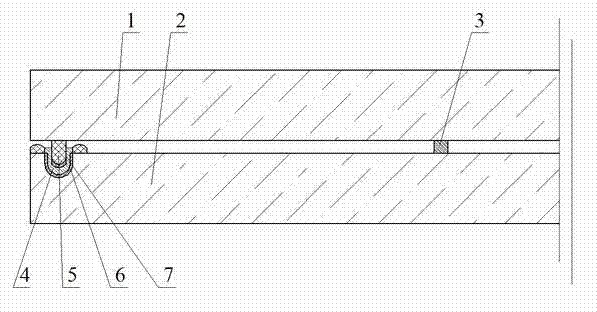

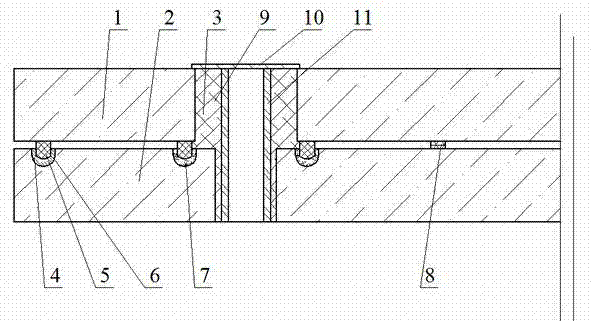

Vacuum glass sealing structure and forming method thereof

InactiveCN104108862AMaintain tempered propertiesAchieve lead-free sealingGlass reforming apparatusMetallurgyLow melting point

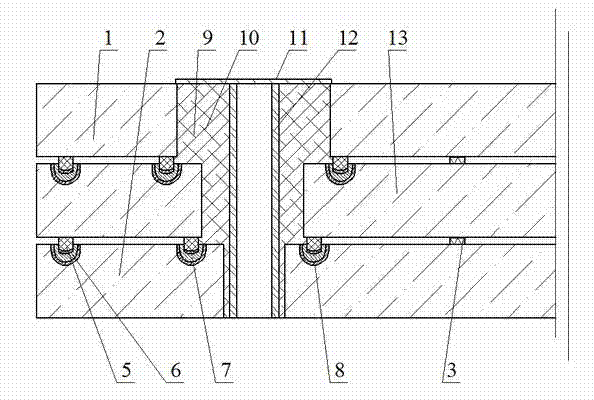

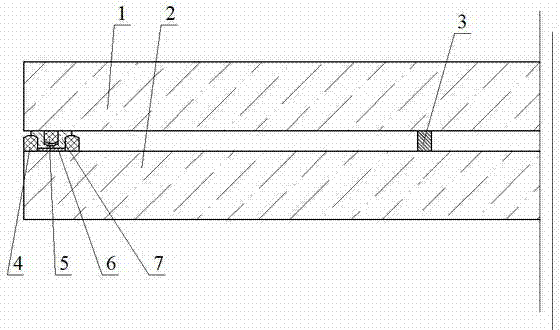

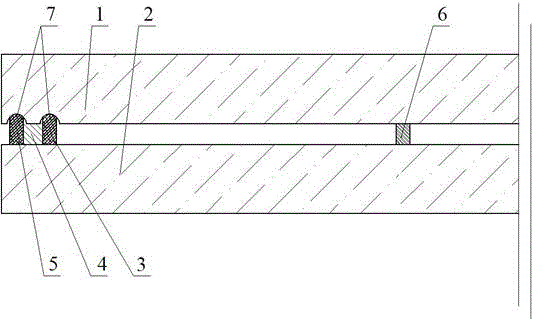

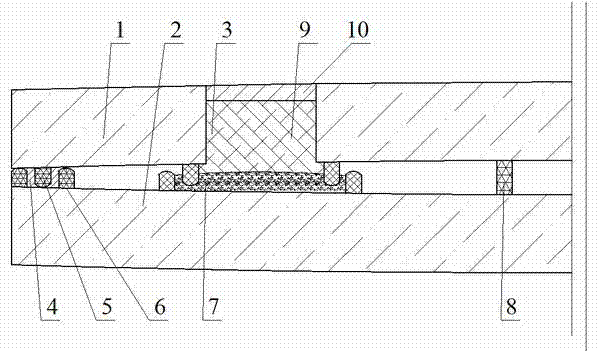

A vacuum glass sealing structure and a method for forming the vacuum glass sealing structure. The vacuum glass sealing structure includes an air-exhausting port (9) which is formed on a glass surface plate (6), a sealing substrate (1) which covers the air-exhausting port (9) and is aligned with the center of the air-exhausting port (9), and a solder (3) which is arranged between the glass surface plate (6) and the sealing substrate (1). The structure is characterized in that the solder (3) is a low-melting-point solder which can melt at 150-350 DEG C.

Owner:BEIJING SYNERGY VACUUM GLAZING TECH

Vacuum-glass heat-insulating board and manufacturing method thereof

InactiveCN105669007ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAir tightness

The invention relates to a vacuum-glass heat-insulating board. The vacuum-glass heat-insulating board comprises upper glass and lower glass, wherein the periphery of the upper glass and the periphery of the lower glass are connected together through a sealing material in a sealing manner, a closed vacuum layer is formed between the upper glass and the lower glass and contains a low-melting-point or volatile or highly-inspiratory metal, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces to the outer side. A manufacturing method for the vacuum-glass heat-insulating board disclosed by the invention is simple in process, the sealing effect is good, the air tightness and service life of the vacuum-glass heat-insulating board can be effectively guaranteed, and mechanized, automated and large-scale production can be achieved.

Owner:戴长虹

Vacuum glass laminated at high temperature and production method thereof

InactiveCN104743842AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a vacuum glass laminated at high temperature, which comprises an upper glass and a lower glass, the upper glass and the lower glass are plane glass or convex glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder or a metal solder in a vacuum furnace, an enclosing vacuum layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the vacuum layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

Vacuum glass insulation panel and preparation method thereof

InactiveCN105669003ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

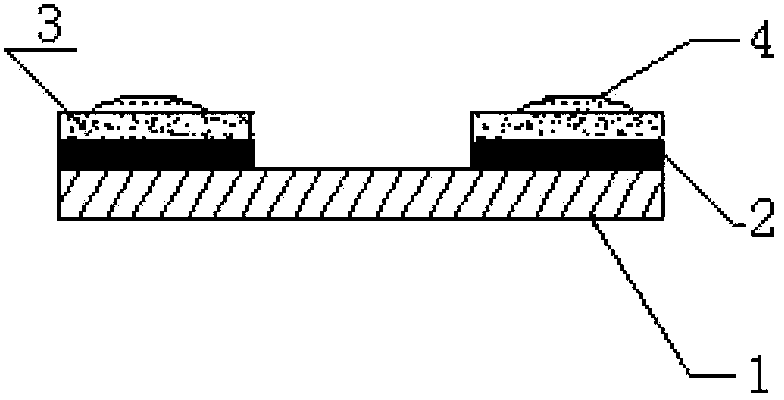

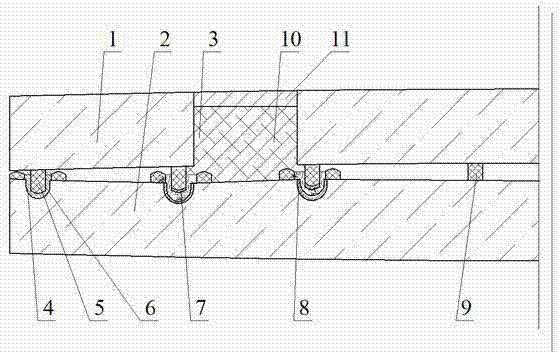

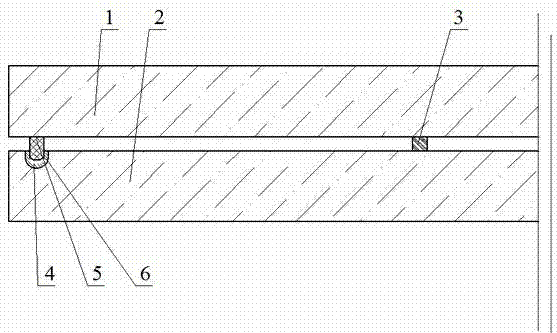

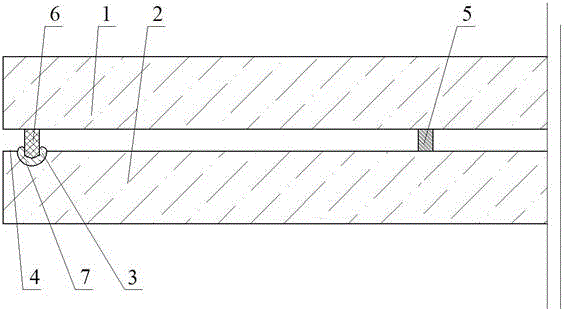

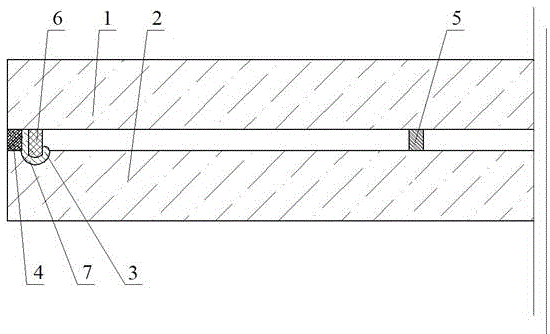

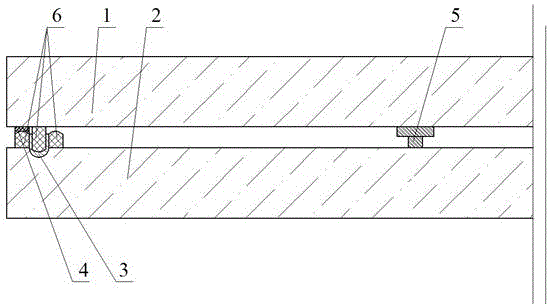

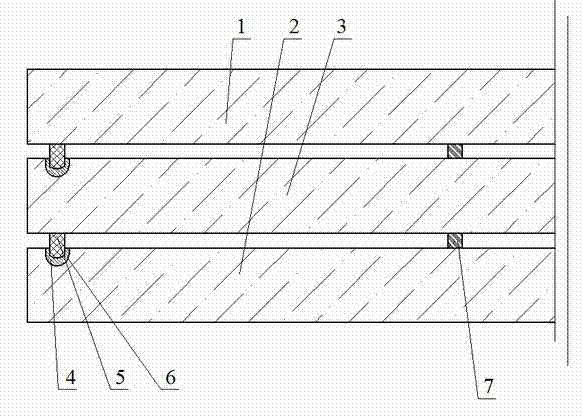

Tempered vacuum glass edge-sealing method and tempered vacuum glass edge-sealing device

InactiveCN102531361AAchieving tempered propertiesStable heating processGlass reforming apparatusToughened glassHeating furnace

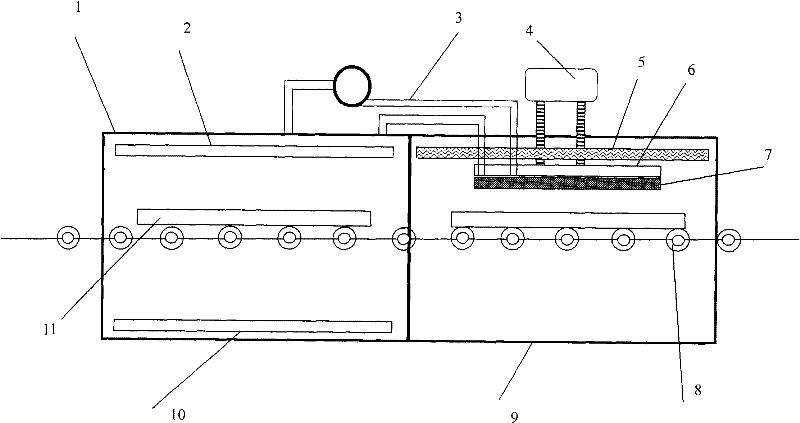

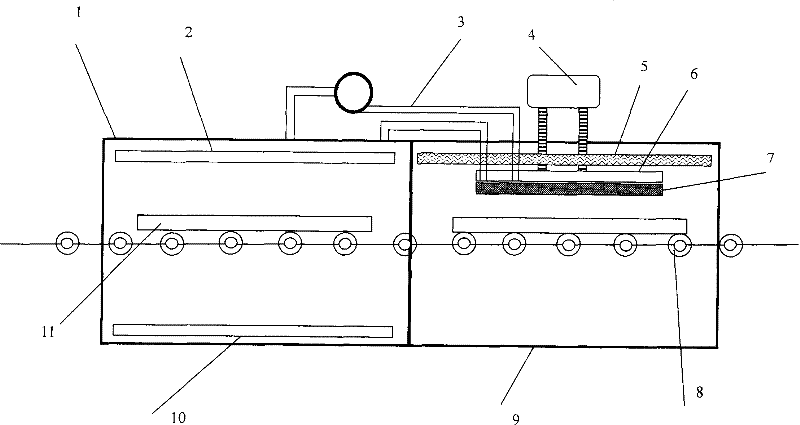

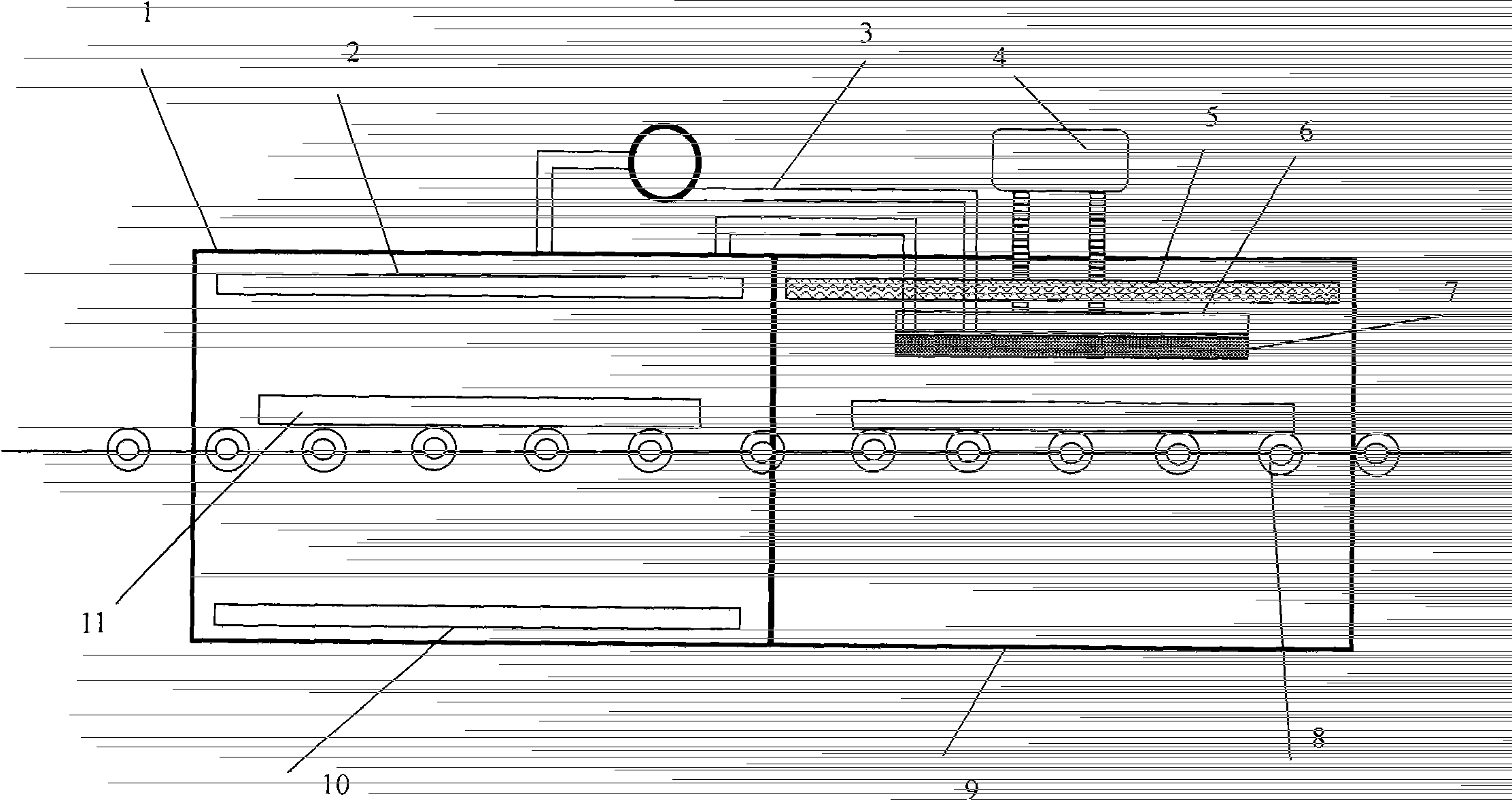

A tempered vacuum glass edge-sealing method utilitzes a constant-temperature metal plate to control the local temperature of a tempered vacuum glass preformed unit according to the thermal stress distribution characteristic of the tempered vacuum glass preformed unit in order to keep the local temperature between 100 DEG C and 400 DEG C in the process of heating and brazing for sealing the circumference of the tempered vacuum glass. A tempered vacuum glass edge-sealing device comprises a second heating furnace, wherein a heating source is arranged on the top in the second heating furnace, the constant-temperature metal plate is arranged in the middle of the second heating furnace, and a heat-dissipating passage is arranged in the constant-temperature metal plate, and is connected with a liquid or gas circulation thermostat. The invention utilizes the constant-temperature metal plate with constant temperture to keep the temperature of the key part of the tempered vacuum glass in order to keep the tempering characteristic in the process of edge sealing. The heating process is stable, the heated area can be controlled, the glass cannot be broken, and the requirements on the mass production of high-quality tempered vacuum glass can be met.

Owner:上海镭立激光科技有限公司

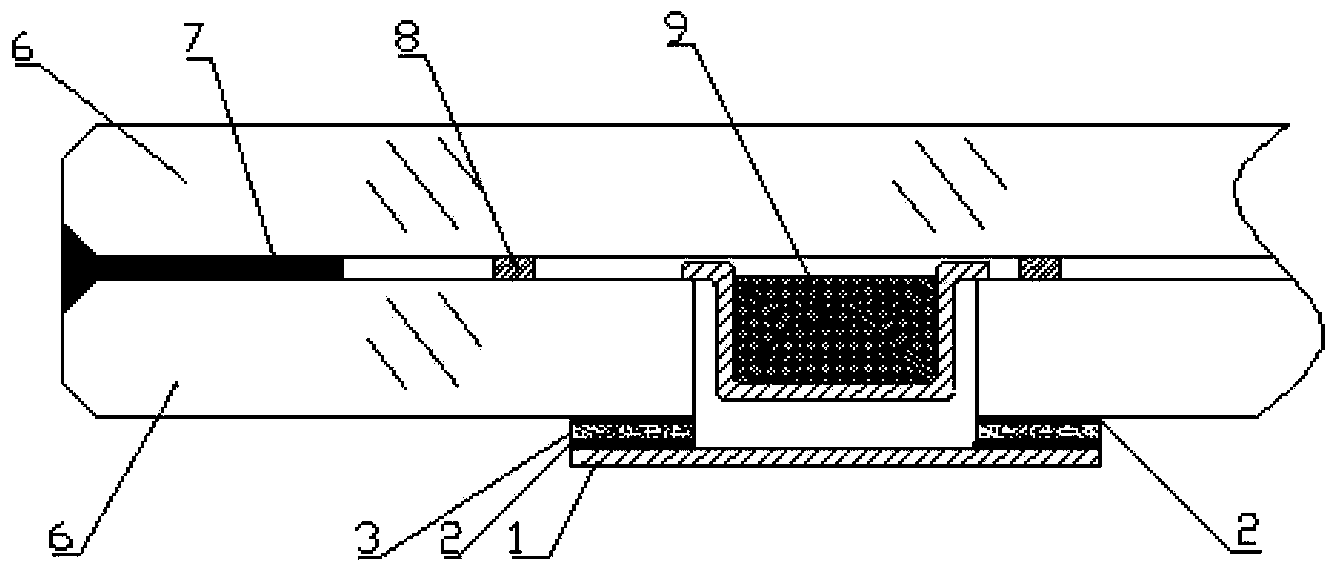

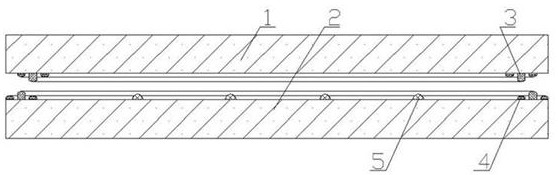

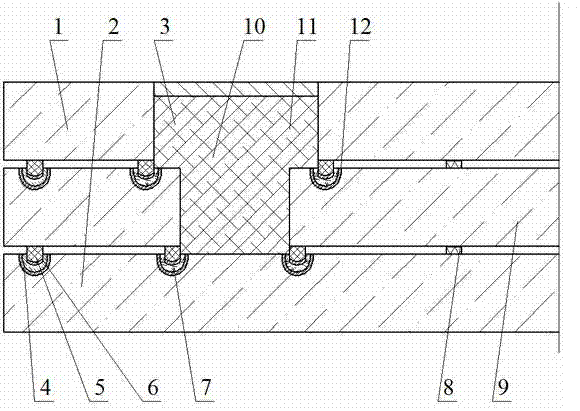

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and manufacturing method thereof

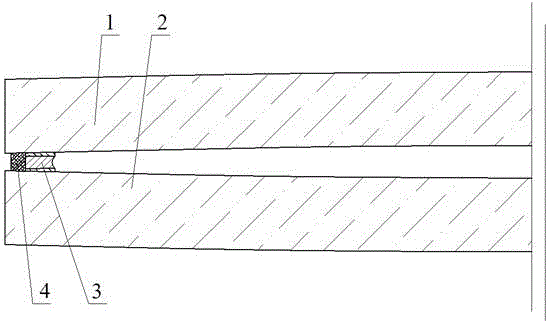

Metal-welded plain vacuum glass provided with edges sealed by sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with at least one sealing strip; the periphery of the lower glass is provided with at least two sealing strips; the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; and after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743825AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Bar-frame sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669005ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a bar-frame vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743805AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

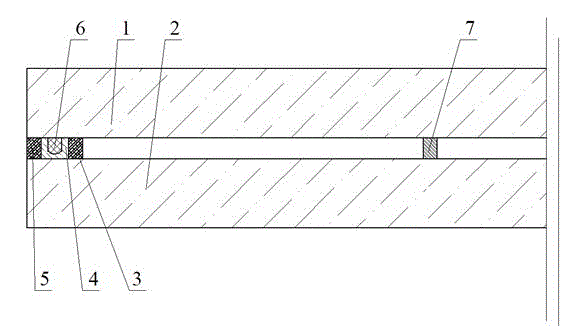

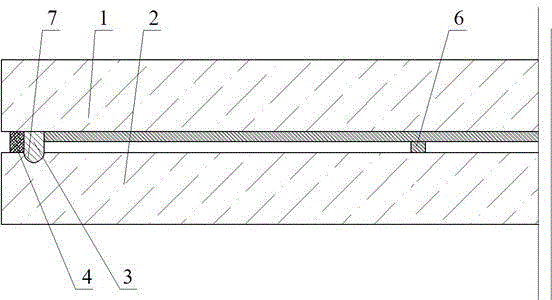

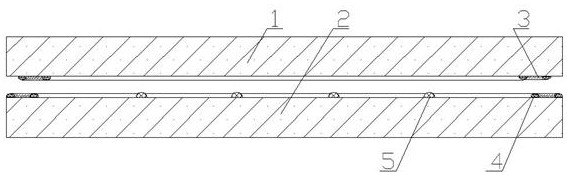

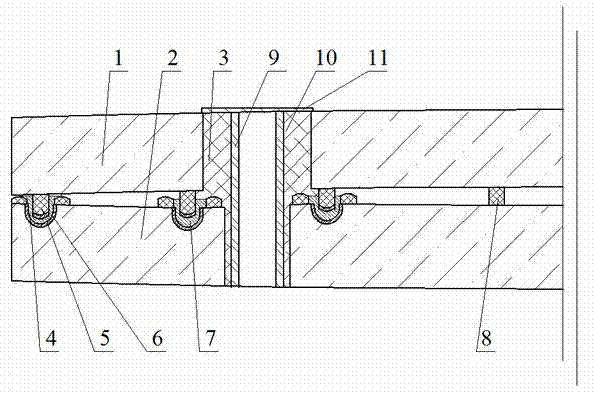

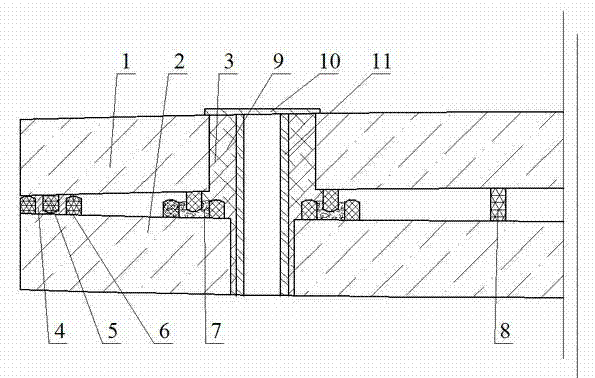

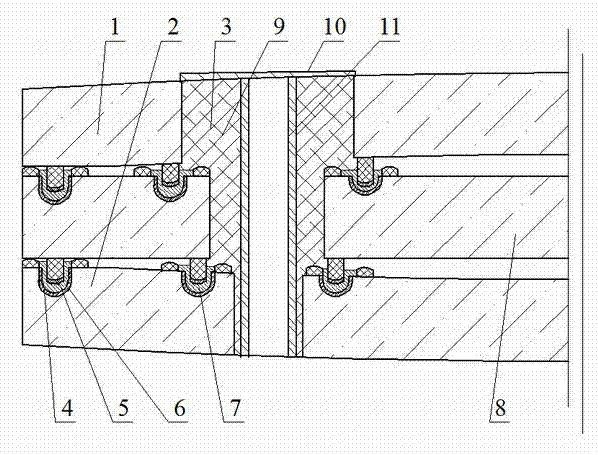

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

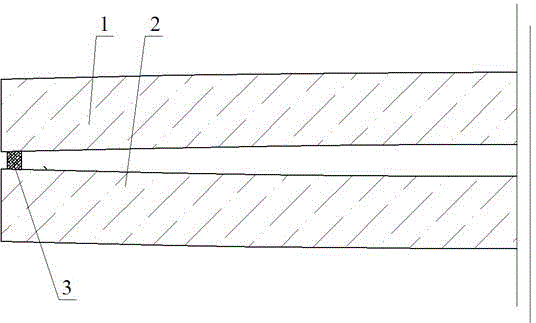

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the periphery of the upper glass is provided with sealing strips; corresponding positions of the periphery of the lower glass are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Groove sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669004ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionAdhesiveFlat glass

The present invention discloses a groove vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips and production method thereof

InactiveCN104743850AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

The invention relates to a glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips, which comprises an upper glass and a lower glass, 1-4 extraction openings are arranged on the upper glass, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are respectively provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Tempered vacuum glass edge-sealing method and tempered vacuum glass edge-sealing device

InactiveCN102531361BNo damageMaintain tempered propertiesGlass reforming apparatusTemperingThermostat

A tempered vacuum glass edge-sealing method utilitzes a constant-temperature metal plate to control the local temperature of a tempered vacuum glass preformed unit according to the thermal stress distribution characteristic of the tempered vacuum glass preformed unit in order to keep the local temperature between 100 DEG C and 400 DEG C in the process of heating and brazing for sealing the circumference of the tempered vacuum glass. A tempered vacuum glass edge-sealing device comprises a second heating furnace, wherein a heating source is arranged on the top in the second heating furnace, the constant-temperature metal plate is arranged in the middle of the second heating furnace, and a heat-dissipating passage is arranged in the constant-temperature metal plate, and is connected with a liquid or gas circulation thermostat. The invention utilizes the constant-temperature metal plate with constant temperture to keep the temperature of the key part of the tempered vacuum glass in order to keep the tempering characteristic in the process of edge sealing. The heating process is stable, the heated area can be controlled, the glass cannot be broken, and the requirements on the mass production of high-quality tempered vacuum glass can be met.

Owner:上海镭立激光科技有限公司

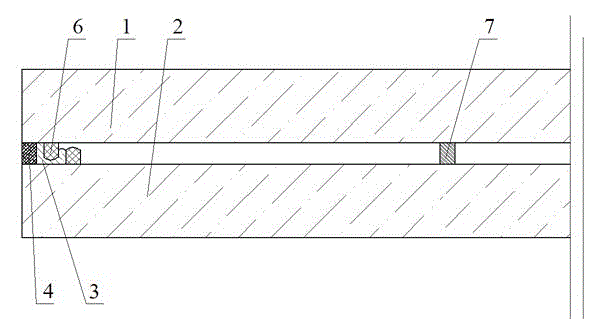

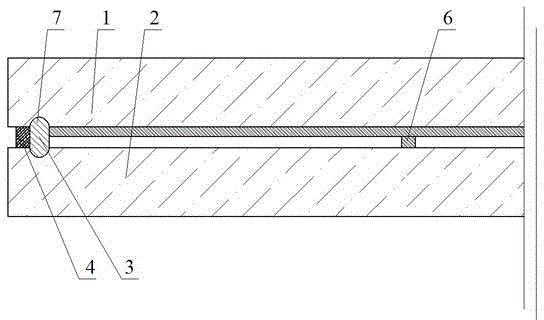

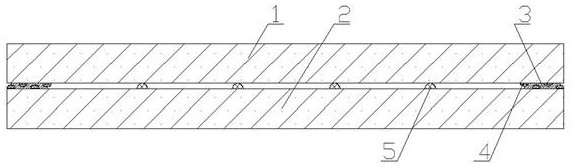

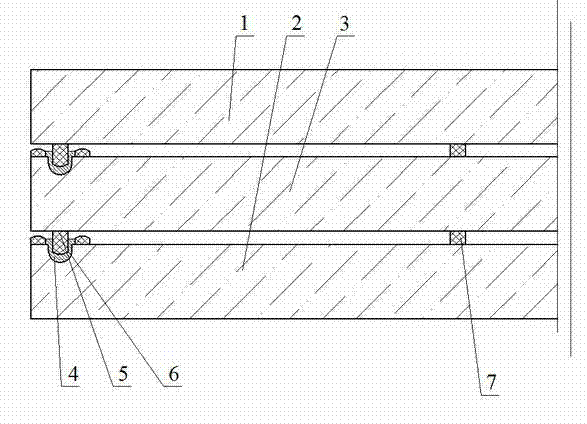

Glass-welded plain vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743832AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass with edges sealed by sealing grooves is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with sealing strips; the periphery of the lower glass is provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Bar-frame and groove sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669002ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a bar-frame and groove sealed vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

Manufacturing method and production line of tempered vacuum glass

InactiveCN112777953AReduce edge temperatureSolve the problem of foamingGlass tempering apparatusAir tightnessGlass manufacture

The invention discloses a manufacturing method and a production line of tempered vacuum glass, and belongs to the technical field of vacuum glass manufacturing. The manufacturing method disclosed by the invention specifically comprises the following steps of: preparing a glass substrate, coating a glass solder and an isolating bar, respectively drying the glass substrate coated with the glass solder and the isolating bar, directly carrying out high-temperature and quenching toughening treatment on the glass substrate without cooling, and then carrying out sheet combination and vacuum edge sealing. According to the manufacturing method and the production line disclosed by the invention, the defects in the prior art can be overcome, low-cost, large-batch and mechanical production of the tempered vacuum glass can be realized, the air tightness and the service life of the tempered vacuum glass can be effectively ensured, the mechanical strength, the heat insulation performance and the sound insulation performance of the vacuum glass can be improved, and the manufacturing method and the production line are suitable for market popularization and application.

Owner:戴海玥

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743818AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass. The plain vacuum glass is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; one sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

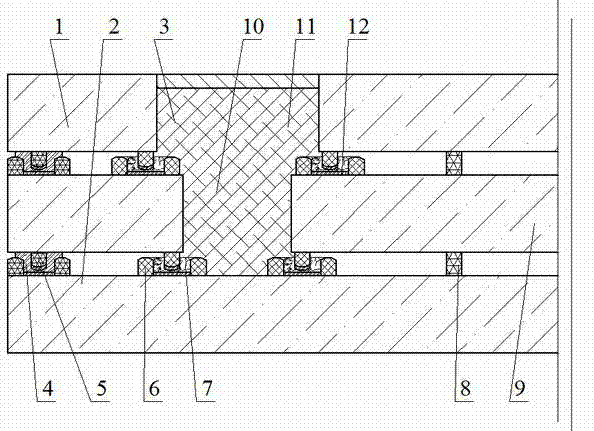

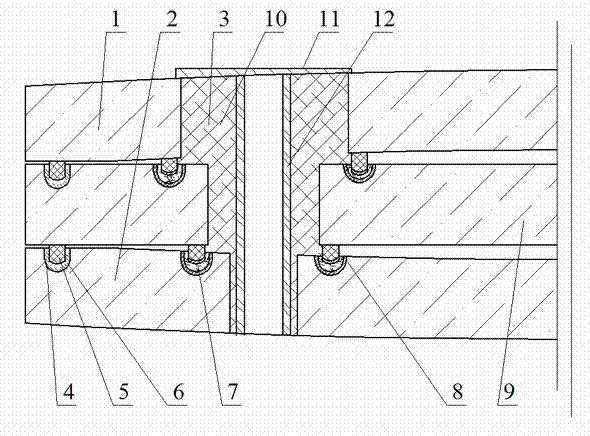

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743792AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

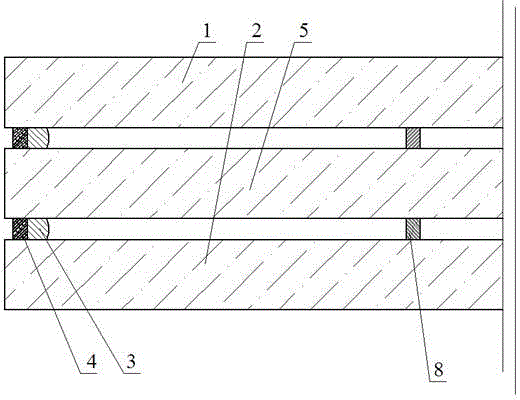

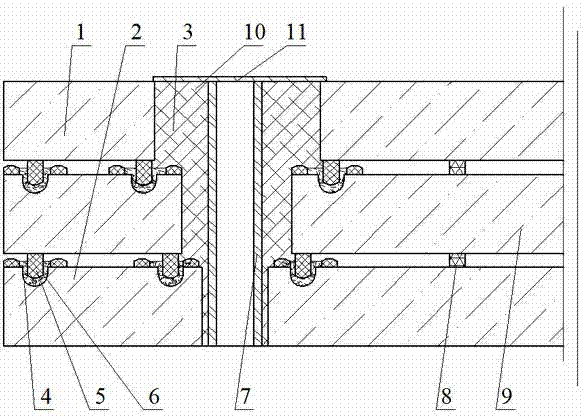

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the plain double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips

The invention relates to a metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through an alloy solder in an atmosphere heating furnace, and the extraction opening is enclosed by using metal solder in vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Metal-welded convex vacuum glass having installing holes by metal welding at sealed edge of sealing strips

The invention relates to a convex vacuum glass having installing holes by metal welding at sealed edge of a sealing strip, which comprises an upper glass and a lower glass, the installing holes are provided, 1-4 installing holes are provided, at least a sealing strip is respectively provided at circumference of the upper glass and the installing hole, at least two sealing strips are provided at circumference of the lower glass, at least a sealing strip is arranged at the lower glass corresponding to the installing hole, the sealing strip of the upper glass is inserted between sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a metal solder in a vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

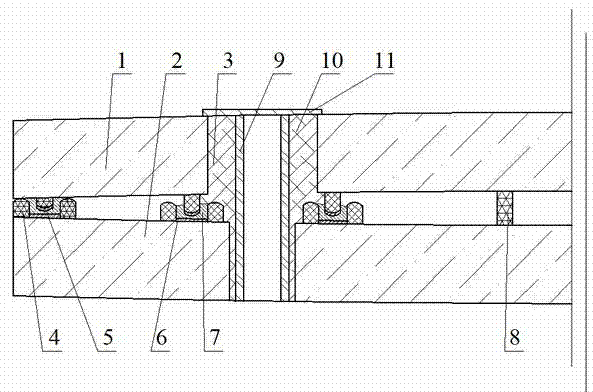

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips

InactiveCN104743852AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

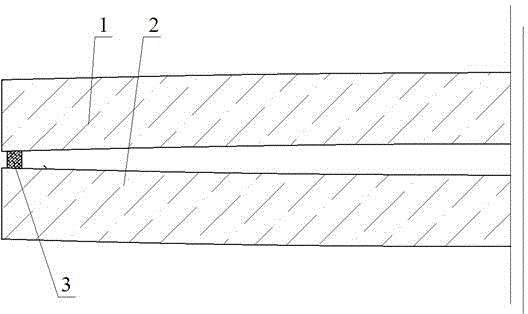

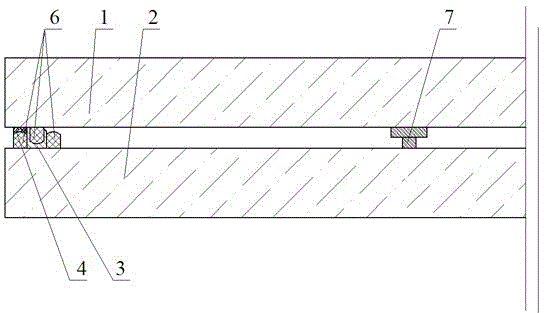

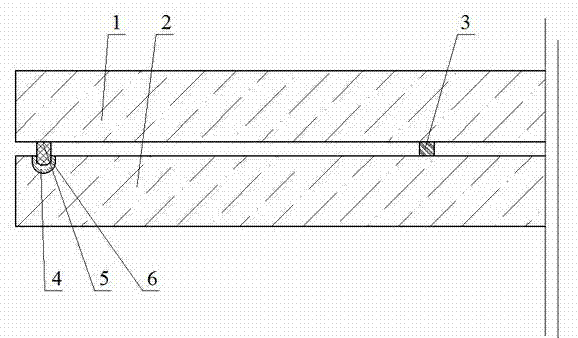

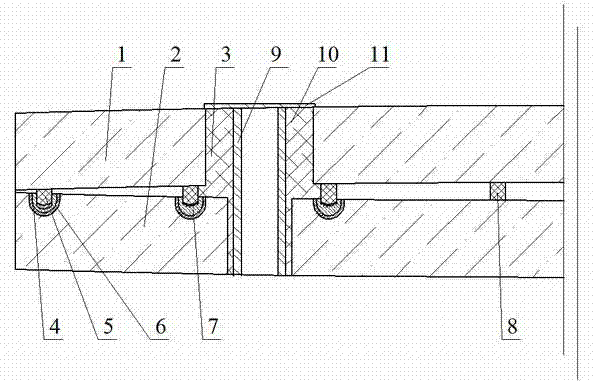

Glass-welded plane glass low-altitude glass with edge sealed by sealing grooves and production method thereof

InactiveCN104743865AShorten the timeMaintain tempered propertiesGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a glass-welded plane glass low-altitude glass with edge sealed by sealing grooves, which comprises an upper glass and a lower glass, a sealing strip is provided at the upper glass, a seal groove is arranged at circumference of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, an enclosing low-altitude layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the low-altitude layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass which are plain glass. The upper glass and the middle glass are provided with one to four air extracting holes. The periphery of the lower surface of the upper glass, the periphery of the lower surface of the middle glass and the periphery of each air extracting hole are respectively provided with at least one sealing strip. The peripheries of the upper surfaces of the middle glass and the lower glass are provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. Peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. A manufacturing method of the plain double-vacuum-layer glass is simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the convex double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

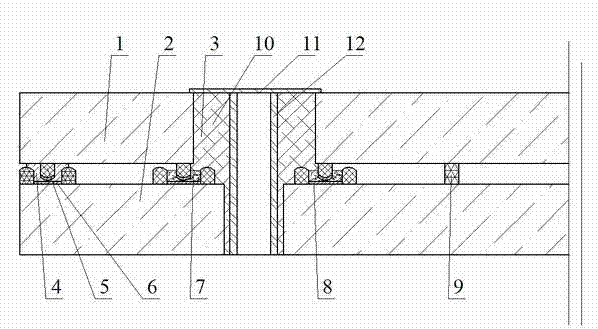

Glass-welded plane double-low altitude-layer glass with edge sealed by sealing grooves and strips and production method thereof

InactiveCN104743855AShorten the timeMaintain tempered propertiesGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a glass-welded plane double-low altitude-layer glass with edge sealed by sealing grooves and strips, which comprises an upper glass, a lower glass and an intermediate glass, the sealing strips are provided at lower surfaces of the upper glass and the intermediate glass, the seal groove and the sealing strips are arranged on the upper surface circumference of the intermediate glass and the lower glass, three glasses are rapidly heated, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and two enclosing low-altitude layers are formed between the upper glass and the intermediate glass as well as between the intermediate glass and the lower glass. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743795AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the upper surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and two vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the upper glass and the lower glass are convex glass; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743833AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the lower surfaces of the upper glass and the middle glass are provided with sealing strips; the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com