Tempered vacuum glass edge-sealing method and tempered vacuum glass edge-sealing device

A technology of vacuum glass and edge sealing device, which is applied in the field of physics, can solve the problem that tempered vacuum glass is difficult to maintain tempering characteristics, etc., and achieves the effect of satisfying the production of large-scale high-quality tempered vacuum glass, stable heating process and controllable heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

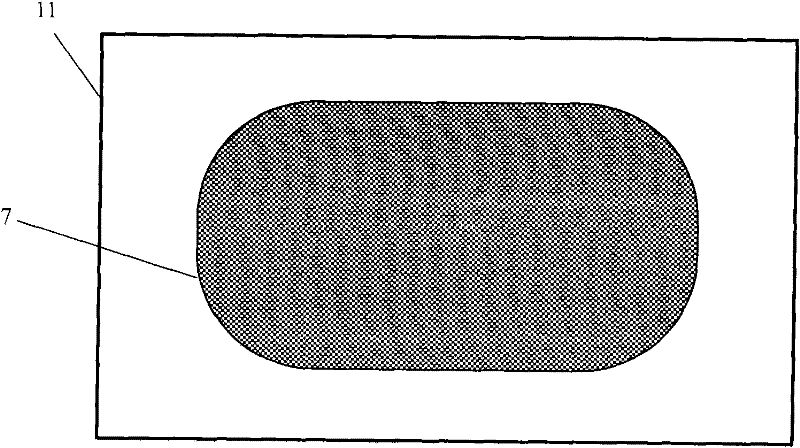

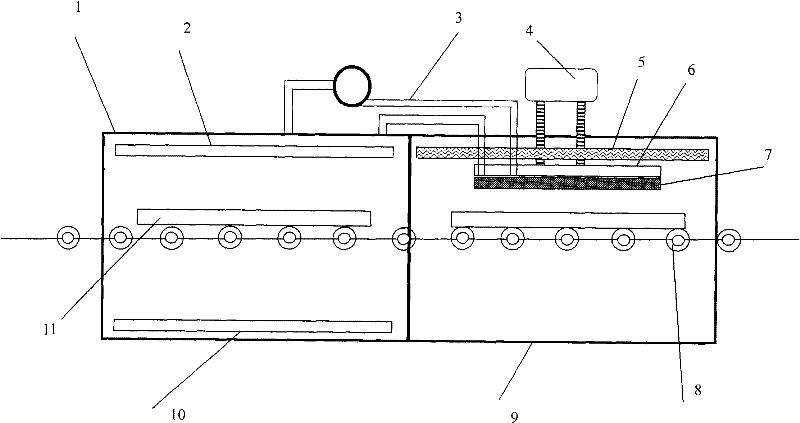

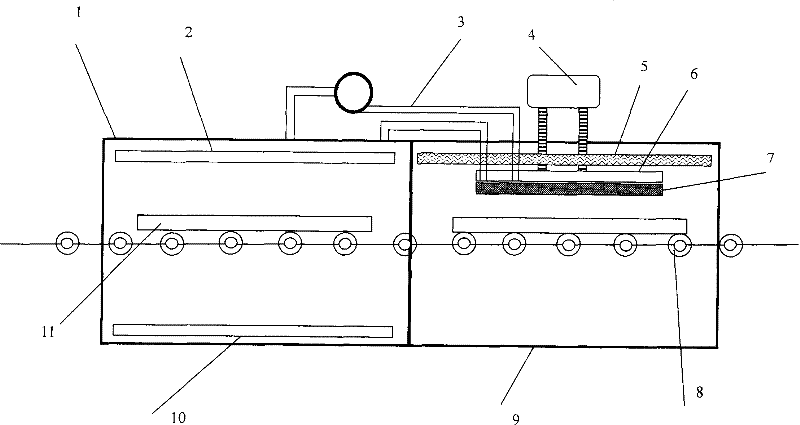

[0026] Such as figure 1 As shown, the edge sealing method of this tempered vacuum glass of the present invention comprises a process of brazing and sealing the tempered vacuum glass with low-melting-point glass brazing material around, and described brazing and sealing toughened vacuum with low-melting-point glass brazing material A step of heating the tempered vacuum glass preform 11 to the melting point temperature of the brazing material is included in the process around the glass, wherein, in the step of heating the tempered vacuum glass preform 11 to the melting point temperature of the brazing material, a constant temperature The metal plate 7 controls the local temperature of the tempered vacuum glass preform 11 according to the thermal stress distribution characteristics of the tempered vacuum glass preform 11, and keeps the local temperature of the tempered vacuum glass preform 11 between 100 degrees Celsius and 400 degrees Celsius.

[0027] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com