Pretreatment device of sample for measuring secondary electron emission characteristic of material

A technology for secondary electron emission and sample pretreatment, which is applied in measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., and can solve problems such as insufficient temperature and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

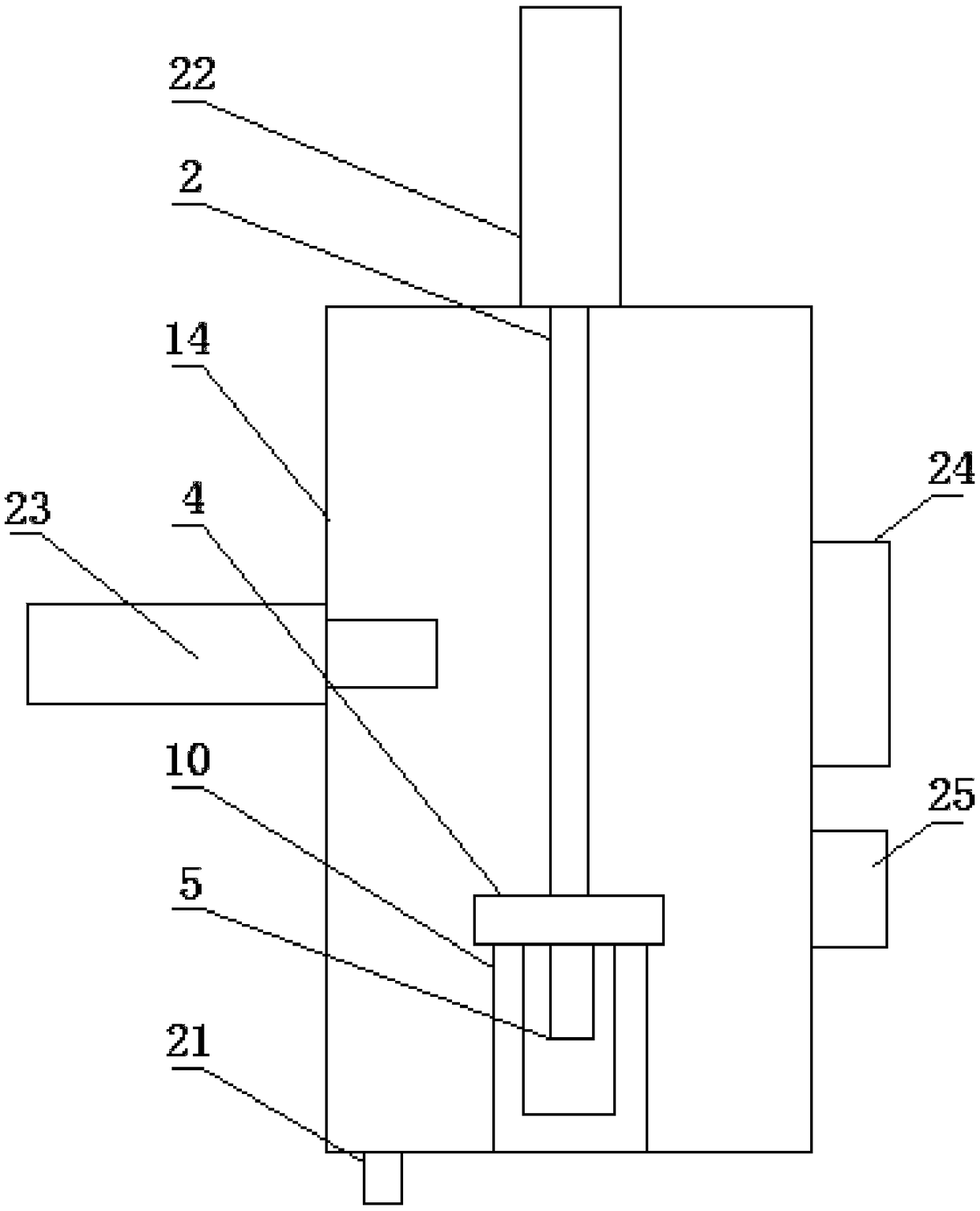

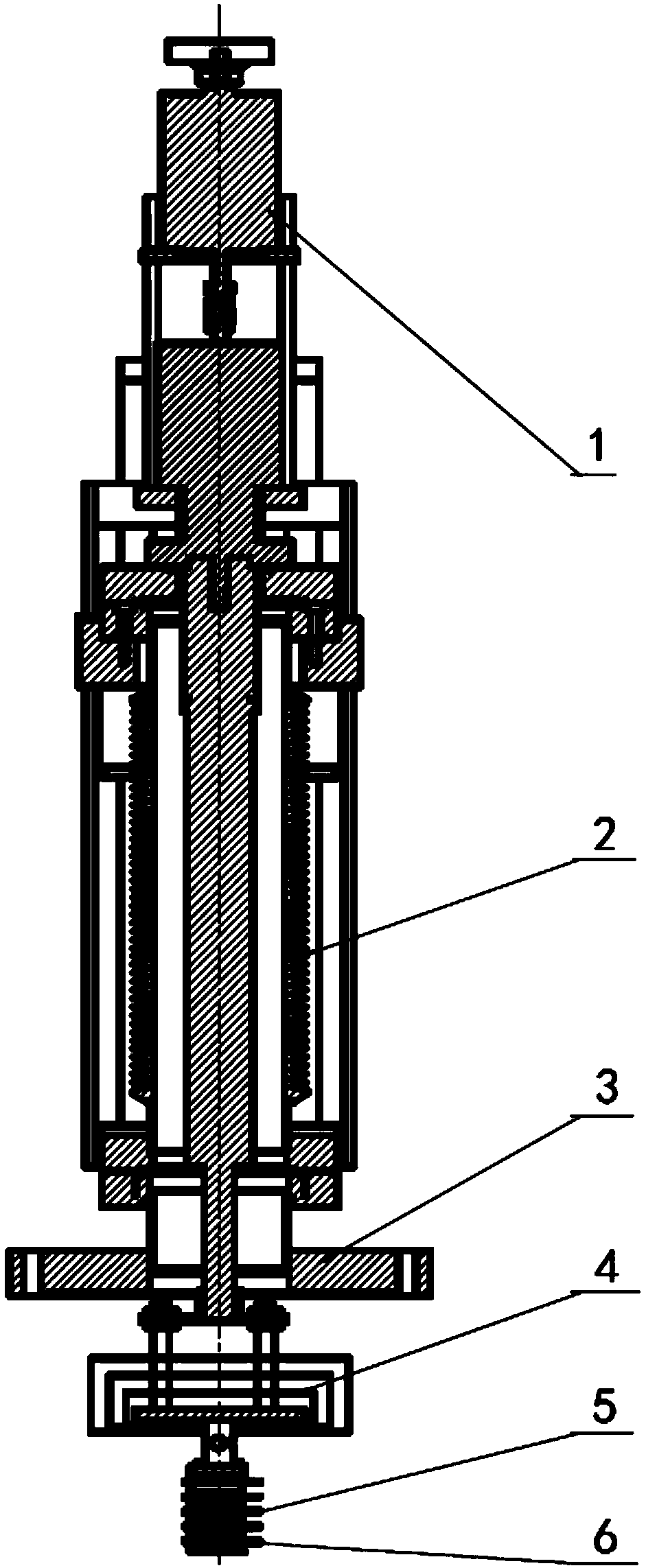

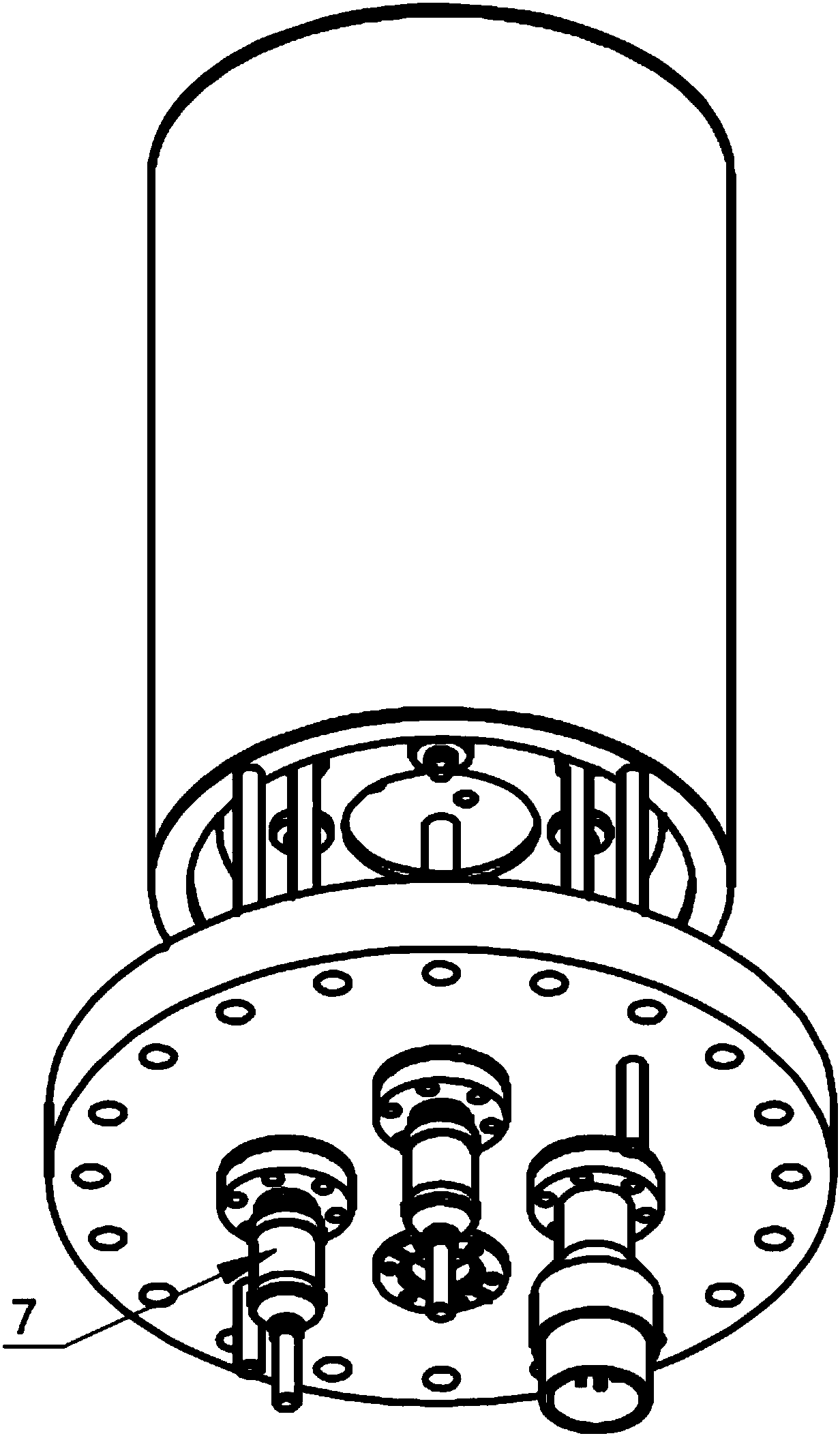

[0039] Such as Figure 1 to Figure 6 As shown, a sample pretreatment device for measuring secondary electron emission characteristics of materials includes a vacuum chamber 14 with a closed space and a vacuum pump 25 connected to the closed space, and also includes a heating device. The heating device includes a barrel-shaped The bottom bucket 10 and the gland 4 as the opening end sealing plate of the bottom bucket 10, the heating device is located in the closed space;

[0040] It also includes a driving part 22 installed on the vacuum chamber 14, the driving part 22 is connected with the gland 4 through the motion transmission part 2, and the driving part 22 is used to drive the gland 4 along the direction of the opening end of the bottom barrel 10. sports;

[0041] It also includes a sample storage platform 5 installed on the gland 4. When the gland 4 is fastened to the open end of the bottom bucket 10, the sample storage platform 5 is located in the bottom bucket 10 and th...

Embodiment 2

[0052] Such as Figure 1 to Figure 6 As shown, this embodiment is further limited on the basis of Embodiment 1: Since the measured samples may have problems of inconsistent volume, shape and size, in order to make the pretreatment device have better adaptability and be able to complete multiple samples at the same time The pretreatment is set as follows: the sample storage platform 5 has a columnar structure, and a plurality of slots are arranged on the side of the sample storage platform 5 . With this solution, multiple slots can be matched with multiple sample trays 6, that is, by inserting the sample tray 6 into the slot, the sample is fixed on the sample tray 6, so that the volume and shape of the sample do not affect the sample storage. The way of installing on the platform 5 improves the adaptability of the pretreatment device to samples; it is set to have multiple slots, so that multiple slots cooperate with multiple sample trays 6, so that multiple samples can be fixed...

Embodiment 3

[0062]This embodiment provides a specific implementation method of a sample pretreatment device for measuring secondary electron emission characteristics of materials. There is a vacuum moving platform connected to the top of the outer periphery of the vacuum chamber 14, and the vacuum moving platform is the driving part 22. The middle part There is a gate valve for the gate part 24 and a molecular pump for the vacuum pump 25 on the opposite side of the magnetic rod for grabbing the transfer part 23. The bottom of the vacuum chamber 14 is connected with an air release valve 21 and a heating control power supply. The power terminal block 20 at the introduction point; the vacuum moving platform is set on the upper part of the vacuum cavity 14, the output end of the vacuum moving platform is located at the lower end, the sample storage table 5 and the gland 4 are connected on the lower end of the vacuum moving platform, and the bottom barrel 10 is located at the gland 4 directly b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com