Ladle cover suitable for ejection burner

A technology of ladle cover and injection type, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of low mechanical strength, blockage of porous heat storage body, damage of refractory materials, etc., to reduce heat loss, Lower discharge temperature and lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

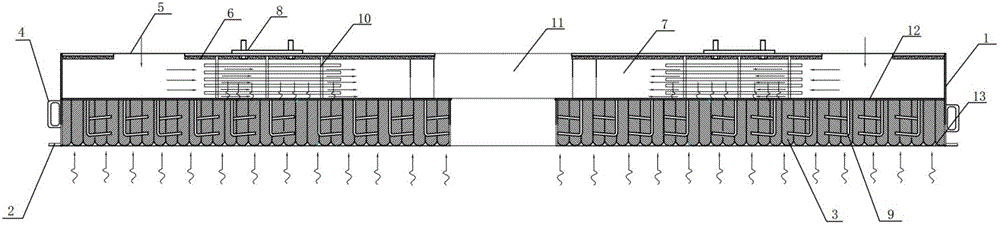

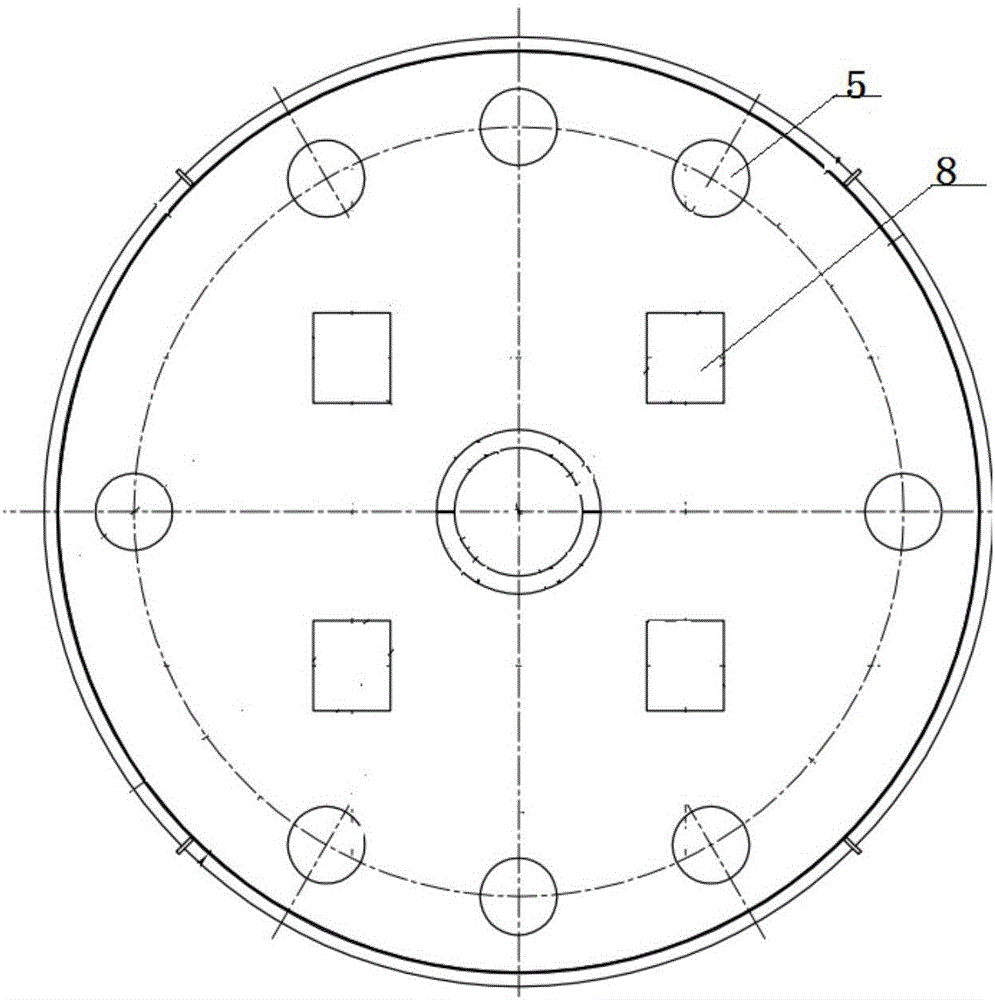

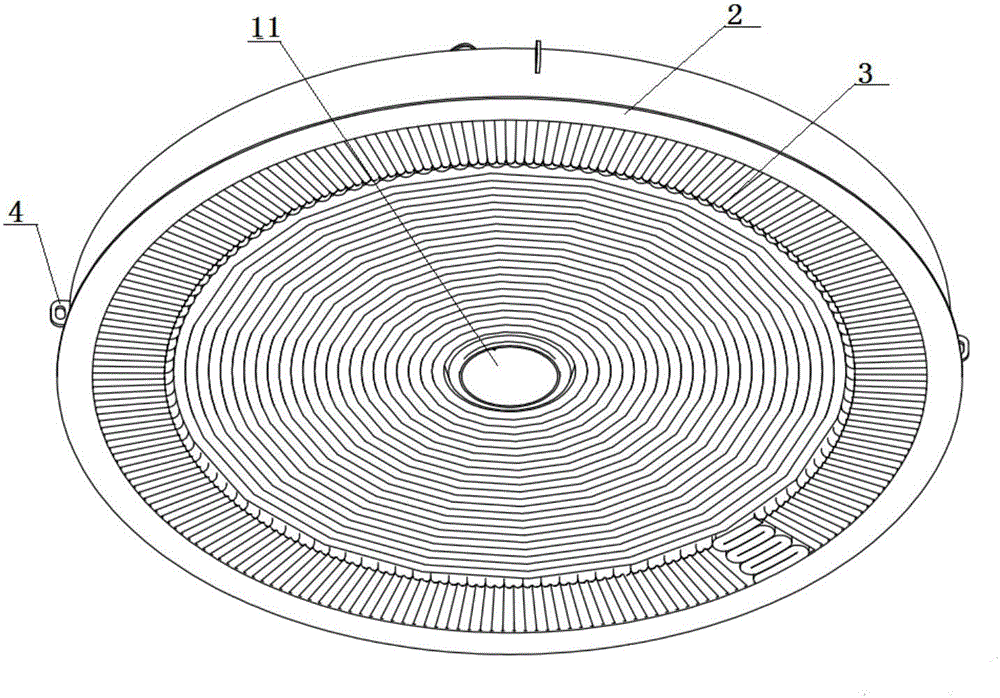

[0029] Such as Figure 1~3 As shown, a ladle cover suitable for injection type burners includes cover body 1, reinforcement ring plate 2, refractory cotton 3, lifting lug 4, air through hole 5, insulation layer 6, inverted F-shaped hanging part 9, Air preheater 10, burner reserved opening 11, partition 12; said partition 12 is arranged in the cavity of cover body 1, and divides the cavity of cover body 1 into upper cavity 7 and lower cavity 13 ; The reserved port 11 for the burner passes through the center of the upper plate of the cover body 1 and the center of the partition 12, and an ejector burner can be installed in the reserved port 11 for the burner. The reinforcing ring plate 2 is arranged on the lower end surface of the cover body 1 to prevent the refractory surface from expanding; The inverted F-shaped hanger 9 is fixed, and the upper end of the inverted F-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com