Solid-liquid separation integrated toilet tool capable of remarkably reducing residues, and applications thereof

A solid-liquid separation and toilet technology, applied in the application, climate change adaptation, chemical instruments and methods, etc., can solve the problems of inability to dry, complex structure, unrealistic, etc., to achieve easy cleaning and maintenance, high efficiency, and good experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

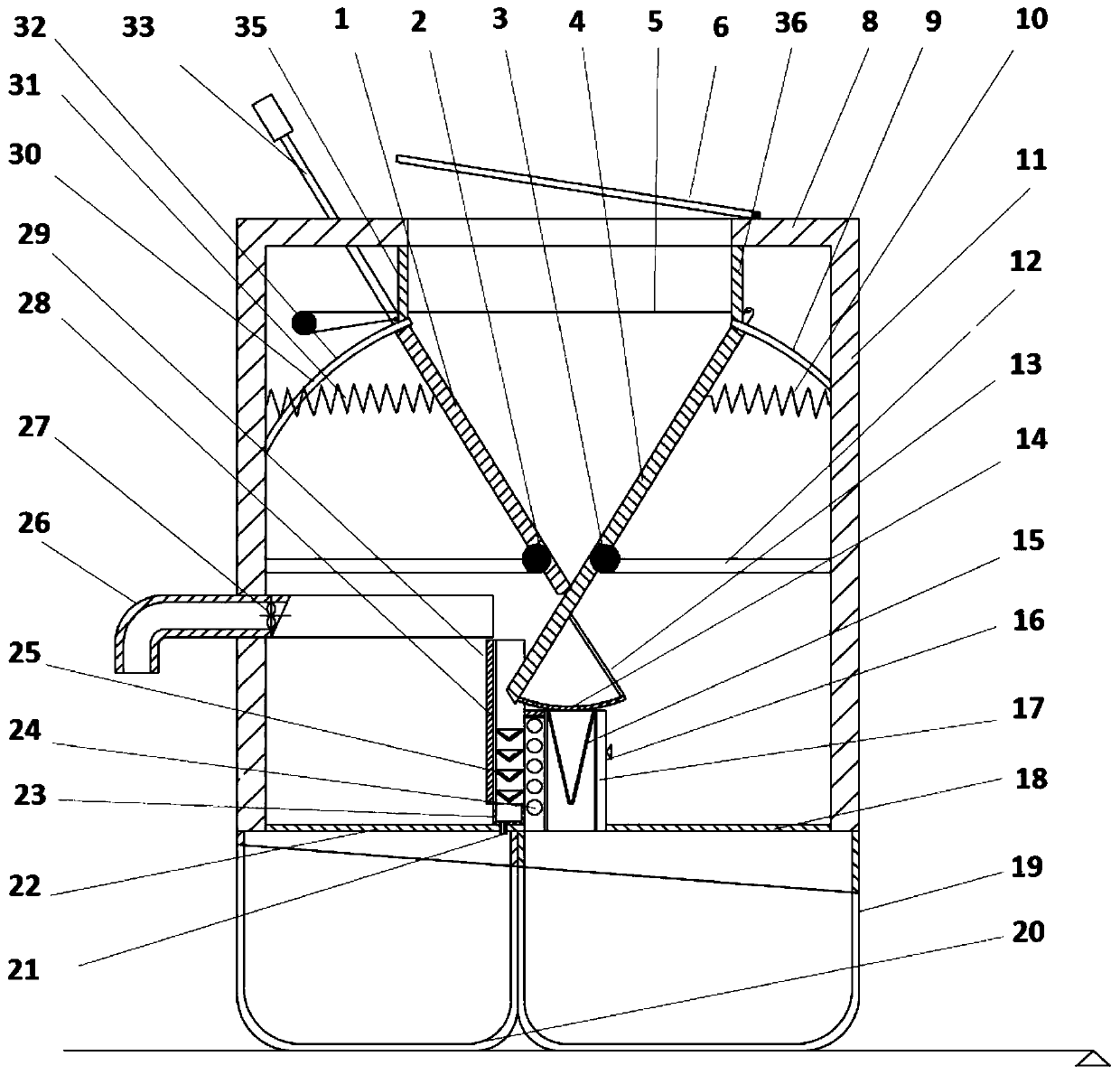

[0047] Such as figure 1 Shown is a schematic diagram of the structure of the solid-liquid separation integrated toilet of the present invention. It can be seen from the figure that the solid-liquid separation integrated toilet of the present invention includes a storage processor, an ash storage 19 and a spare liquid storage 20, wherein the storage processor and the backup storage The liquid container 20 and the ash storage device 19 are connected, and the storage processor includes a housing 8 and a storage extrusion device arranged inside the housing, and a baking processing equipment, and the baking processing equipment includes a baking device 24, a liquid processing device and a solid processing device . Each component can be designed under the ground or on the ground. For example, a support and pick-and-place space structure can be built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com