High-hydroxyl methylated melamine resin and preparation method thereof

A technology of high hydroxy methyl etherified melamine and melamine, applied in the direction of coating, etc., can solve the problems of high baking temperature of methyl etherified melamine resin, unable to use water-based paint, high energy consumption, etc., achieving good water solubility and saving process time, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The high hydroxyl methyl etherified melamine resin comprises the following raw materials: melamine, formaldehyde solution, methanol and formic acid, wherein the weight ratio of melamine, formaldehyde solution and methanol is 2:8:12; the weight ratio of formic acid and melamine is 1 :5.

[0014] The preparation method of the high-hydroxy methyl etherified melamine resin comprises the following steps: first, mix melamine and formaldehyde aqueous solution in proportion, adjust the pH to 9.5 with NaOH solution, heat up to 65°C, and keep warm for 90 minutes; then add in proportion Methanol, then add formic acid according to the ratio of formic acid: melamine weight ratio of 1:5, keep warm for etherification reaction at 50°C for 60 minutes, add NaOH solution to adjust the pH to 9.0, and finally dealcoholize and dehydrate under negative pressure, filter to obtain the resin finished product.

Embodiment 2

[0016] The high hydroxyl methyl etherified melamine resin comprises the following raw materials: melamine, formaldehyde solution, methanol and formic acid, wherein the weight ratio of melamine, formaldehyde solution and methanol is 2:10:15; the weight ratio of formic acid and melamine is 1 :5.

[0017] The preparation method of the high-hydroxy methyl etherified melamine resin comprises the following steps: first, mix melamine and formaldehyde aqueous solution in proportion, adjust the pH to 9.0 with NaOH solution, heat up to 70°C, and keep warm for 90 minutes; then add in proportion Methanol, then add formic acid according to the ratio of formic acid: melamine weight ratio of 1:5, keep warm for etherification reaction at 45°C for 60 minutes, add NaOH solution to adjust the pH to 9.0, and finally dealcoholize and dehydrate under negative pressure, filter to obtain the resin finished product.

Embodiment 3

[0019] The high hydroxyl methyl etherified melamine resin comprises the following raw materials: melamine, formaldehyde solution, methanol and formic acid, wherein the weight ratio of melamine, formaldehyde solution and methanol is 3:11:20; the weight ratio of formic acid and melamine is 1 :5.

[0020] The preparation method of the high-hydroxy methyl etherified melamine resin comprises the following steps: first, mix melamine and formaldehyde aqueous solution in proportion, adjust the pH to 8.5 with NaOH solution, heat up to 75°C, and keep warm for 90 minutes; then add in proportion Methanol, then add formic acid according to the ratio of formic acid: melamine weight ratio of 1:5, keep warm at 40°C for etherification reaction for 60 minutes, add NaOH solution to adjust the pH to 9.0, and finally dealcoholize and dehydrate under negative pressure, filter to obtain the resin finished product.

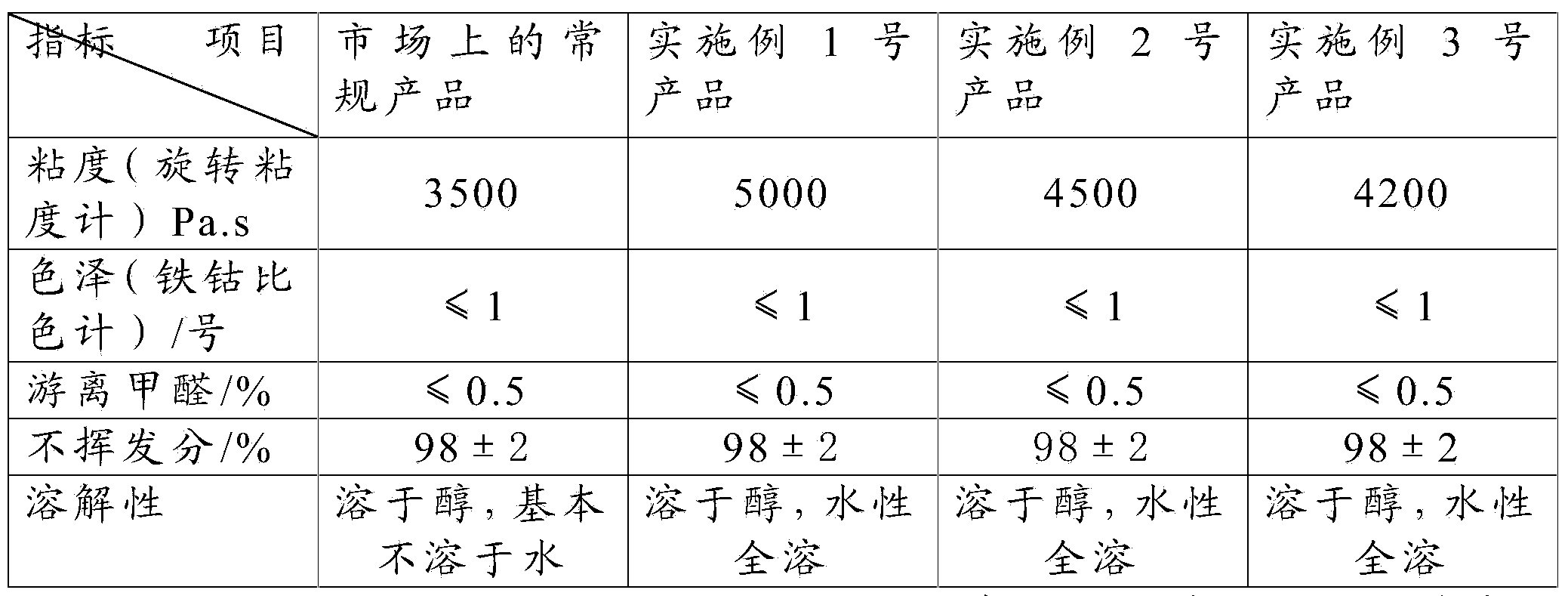

[0021] Embodiment 1, embodiment 2, embodiment 3 compare the following table with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com