Aqueous ultraviolet-curing transparent prime coat and preparation method thereof

A transparent primer and ultraviolet light technology, applied in the direction of biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problem of unsatisfactory yellowing resistance, sterilization can not meet the sterilization requirements, water resistance It can not meet the problems such as excellent environmental protection performance, short construction period and good yellowing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Water-based UV-curing transparent primer for spraying

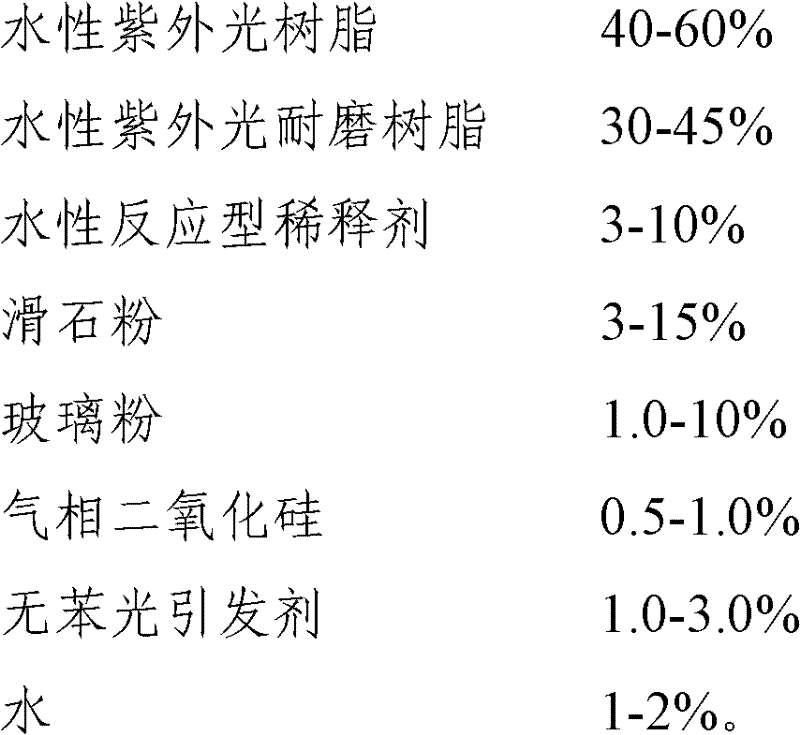

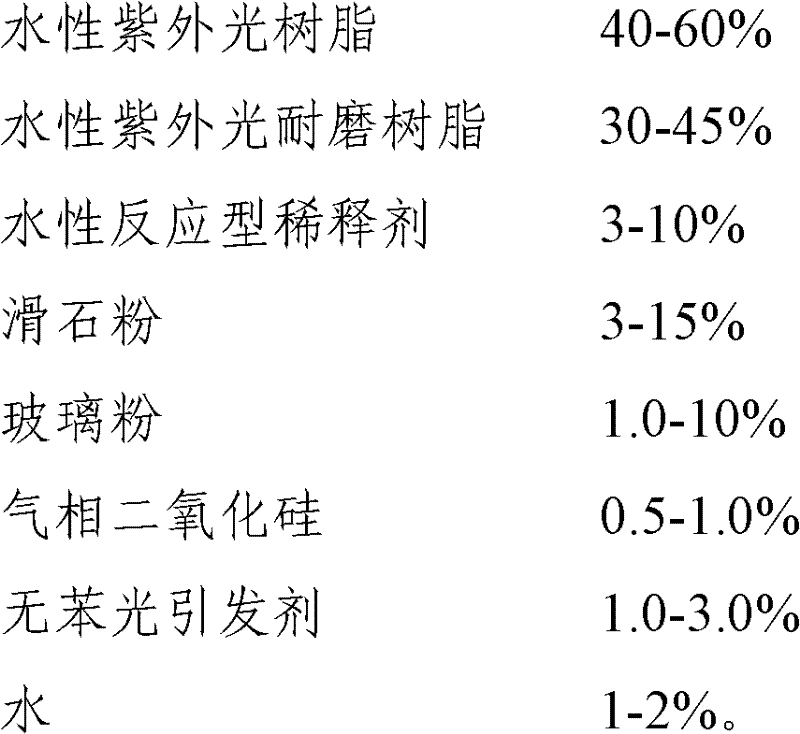

[0059] 1. The composition of raw materials is as follows:

[0060] composition

[0061] 2. Preparation method:

[0062] 1) First, add UV LS2348, SU-N78 and HEMA to the cylinder and disperse at medium speed for 10 minutes, then add TP1250, JG3000, A200 under stirring, and stir evenly and disperse at high speed for 15 minutes;

[0063] 2) The photoinitiators IHT-PI6022 and TEGO810 were dispersed at medium speed for 10 minutes;

[0064] 3) Add K-20, TEGO245, AMP-95, PU40 and water, stir evenly, adjust the pH value to 8-9, and adjust the viscosity to 40-60KU / 25℃ to obtain the product.

[0065] 3. The test results are as follows:

[0066] Indicator

[0067] The results show that: the transparent primer of this embodiment is cured by ultraviolet light, and the hardness reaches more than 3H (tested in GB / T1730-1993), and the fullness is good, the yellowing resistance is good, the solid co...

Embodiment 2

[0068] Example 2: Water-based UV-curing transparent primer for spraying

[0069] 1. The composition of raw materials (weight percentage) is as follows:

[0070] composition

[0071] 2. Preparation method: same as Example 1, just adjust the viscosity to 65KU / 25℃.

[0072] 3. The test results are as follows:

[0073] Indicator

[0074] The results show: the benzene content mg / M of the transparent primer of this embodiment before and after construction 2 The effect is less than or equal to 0.003, almost odorless, free of toxic and harmful substances such as triphenyl, formaldehyde and free TDI, and the heavy metal content is far lower than the European standard.

Embodiment 3

[0075] Example 3: Water-based UV-curing transparent primer for spraying

[0076] 1. The composition of raw materials (weight percentage) is as follows:

[0077] composition

[0078] 2. Preparation method:

[0079] 1) First, add UV LS2348, SU-N78 and HEMA to the cylinder and disperse at medium speed for 10 minutes, then add TP1250, JG3000, A200 under stirring, and stir evenly and disperse at high speed for 15 minutes;

[0080] 2) The photoinitiators IHT-PI6022 and TEGO810 were dispersed at medium speed for 10 minutes;

[0081] 3) Add K-20, TEGO245, AMP-95, PU40 and water, stir evenly, adjust the pH value to 8-9, and adjust the viscosity to 40-60KU / 25℃ to obtain the product.

[0082] 3. The test results are as follows:

[0083] Indicator

[0084] The results show: the benzene content mg / M of the transparent primer of this embodiment before and after construction 2 Functional product with no higher than 0.003 effect, almost odorless.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com