Low-temperature quick-drying dual-component automotive trim paint

An automotive interior, two-component technology, used in the field of interior paint, can solve the problems of wear resistance, hardness, water resistance, poor aging, performance cannot be guaranteed, and the paint film cannot be completely dried.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

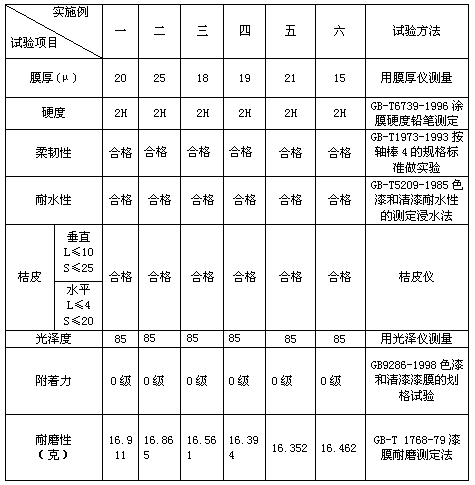

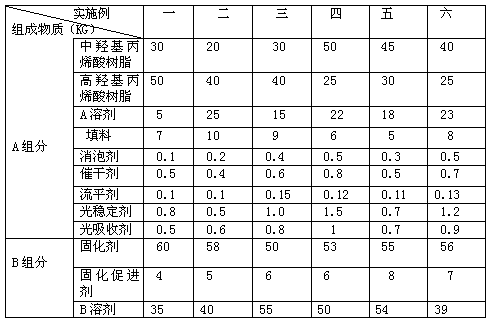

Examples

Embodiment Construction

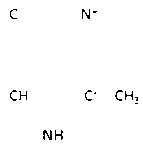

[0009] On the basis of optimizing the ratio of the existing two-component automotive interior paint, the invention adds the curing accelerator 2-methylimidazole to the B component, so as to solve the problems of high baking temperature and long baking time, and improve the The hardness and wear resistance of the paint film are improved. The curing accelerator added in component B is (2-methylimidazole), which can be decomposed into:

[0010]

[0011] The curing accelerator is decomposed into ions, which promotes the curing reaction between the curing agent and the resin, and can cure quickly. The molecular structure of 2-methylimidazole is a pentacyclic structure, forming a π bond. The molecular structure is relatively stable and hard, which enhances the hardness and wear resistance of the paint film. At the same time, the molecular structure contains strong polar groups, -NH- promotes the interaction between molecules and has a self-lubricating effect. Three products are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com