High-frequency copper-clad plate composition applied to antenna base material

A technology of communication antenna and copper clad laminate, applied in the field of high frequency copper clad laminate composition, can solve the problems of size expansion and shrinkage, high equipment requirements, small molecular weight, etc., to improve heat resistance and tensile strength, low thermal expansion coefficient, improve Effect of Crosslink Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

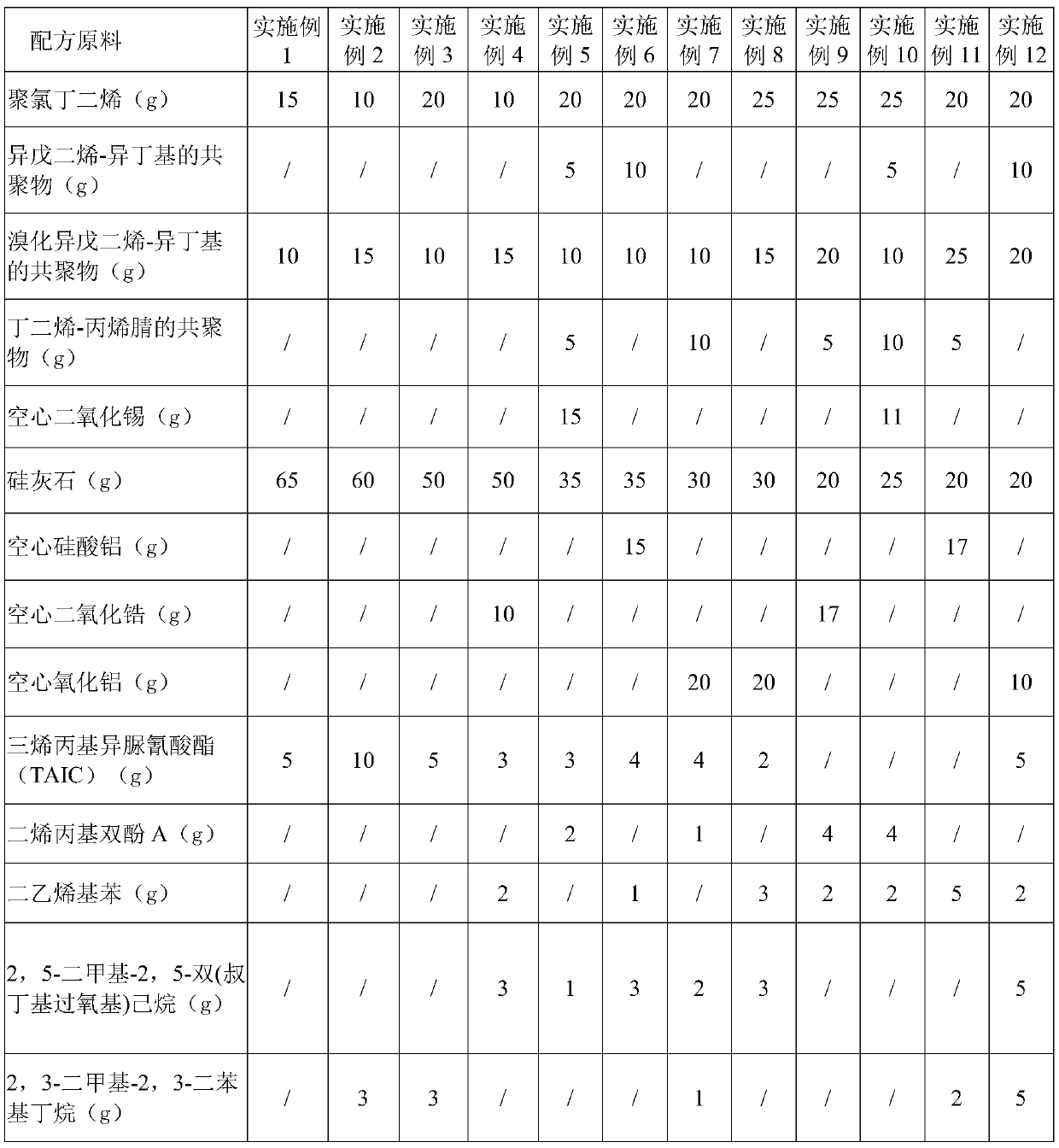

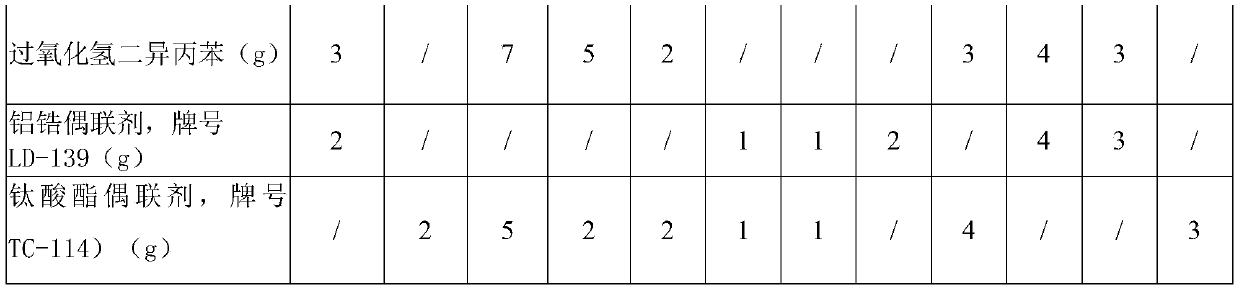

[0031] The preparation method of the copper-clad laminate base material in the following examples 1-12 and comparative examples 1-9 is as follows: the raw materials of the high-frequency copper-clad laminate composition applied to the communication antenna base material of the present invention are added to xylene and stirred evenly, and then used Adjust the appropriate viscosity with xylene (viscosity is 15-30 seconds, No. 4 viscosity cup test) to prepare the glue, use 1080 glass fiber cloth to impregnate the glue, dry to remove the solvent to get a prepreg, the thickness of the prepreg on both sides is 1 ounce (35um Thick) copper foil, through hot press, control material temperature at 230-270 ℃, and heat preservation 180min, press and form, the raw material ratio of embodiment 1-12 is shown in Table 1, the raw material ratio of comparative example 1-9 See Table 2. The properties of the copper-clad laminate substrates prepared in Examples 1-12 are shown in Table 3. The proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com