Pipeline hot melt adhesive and preparation method thereof

A technology of hot melt adhesives and pipes, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems that cannot meet the requirements of pipeline anticorrosion, have many other components, lose stability, etc., and achieve The effect of excellent thermal stability, good market prospect and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

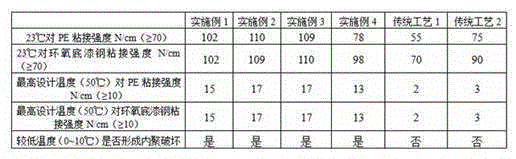

Examples

Embodiment 1

[0037] A composition ratio (percentage by weight) of hot melt adhesive for pipelines:

[0038] Matrix resin 64%;

[0039] Terpene phenolic resin 20%;

[0040] Ethylene-acrylate-maleic anhydride copolymer 15%;

[0041] Antioxidant 1%;

[0042] In the matrix resin, styrene-butadiene-styrene block copolymer accounts for 20% (weight percent) and ethylene-vinyl acetate copolymer accounts for 80% (weight percent)

[0043] Among them, the S / B ratio in styrene-butadiene-styrene block copolymer is 30 / 70; ethylene-vinyl acetate copolymer (EVA) (VA content 28%, melt index 25~150g / 10min) ; Ethylene - acrylate - maleic anhydride copolymer, Vicat softening point of 66 ° C; terpene phenol resin, ring and ball softening point of 100 ° C.

[0044] Preparation method: According to the above ratio, first mix styrene-butadiene-styrene block copolymer, ethylene-vinyl acetate copolymer and antioxidant: 0.5%, and mix them evenly, and granulate them through a twin-screw extruder. The prepared pa...

Embodiment 2

[0046] Component ratio (percentage by weight) of pipeline hot melt adhesive:

[0047] Matrix resin 49%

[0048] Terpene resin 35%;

[0049] Ethylene-acrylate-maleic anhydride copolymer 15%;

[0050] Antioxidant 1%.

[0051] In the matrix resin, styrene-butadiene-styrene block copolymer accounts for 10% (weight percent) and ethylene-vinyl acetate copolymer accounts for 90% (weight percent)

[0052] Among them, the S / B ratio in styrene-butadiene-styrene block copolymer is 40 / 60; ethylene-vinyl acetate copolymer (EVA) (VA content 30%, melt index 400g / 10min); ethylene -Acrylic ester-maleic anhydride copolymer, the Vicat softening point is 60°C; terpene resin, the Ring and Ball softening point is 90°C.

[0053] Preparation method: According to the above ratio, first mix styrene-butadiene-styrene block copolymer, ethylene-vinyl acetate copolymer and antioxidant: 0.2% evenly, and granulate through a twin-screw extruder. Particles, terpene resin and antioxidant: add 1% into the k...

Embodiment 3

[0055] Component ratio (percentage by weight) of pipeline hot melt adhesive:

[0056] Base resin 42%

[0057] Rosin resin 46%;

[0058] Ethylene-acrylate-maleic anhydride copolymer 10%;

[0059] Antioxidant 2%.

[0060] In the matrix resin, styrene-butadiene-styrene block copolymer accounts for 30% (weight percent) and ethylene-vinyl acetate copolymer accounts for 70% (weight percent)

[0061] Among them, the S / B ratio in styrene-butadiene-styrene block copolymer is 20 / 80; ethylene-vinyl acetate copolymer (EVA) (VA content 30%, melt index 10g / 10min); ethylene -Acrylic ester-maleic anhydride copolymer, the Vicat softening point is 35°C; rosin resin, the Ring and Ball softening point is 90~100°C.

[0062] Preparation method: According to the above ratio, first mix styrene-butadiene-styrene block copolymer, ethylene-vinyl acetate copolymer and antioxidant: 1% evenly, and granulate through a twin-screw extruder. Obtained particle and rosin resin, antioxidant: 1% is added into k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com