Antifogging agent composition, and antifogging article with antifogging coating film

A composition and anti-fogging agent technology, applied in the direction of coating, etc., can solve the problems of reducing the brightness of the vehicle lamp, damaging the aesthetics of the lens surface, and user discomfort, achieving good anti-fogging performance, good curing reaction, and promoting curing reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097]

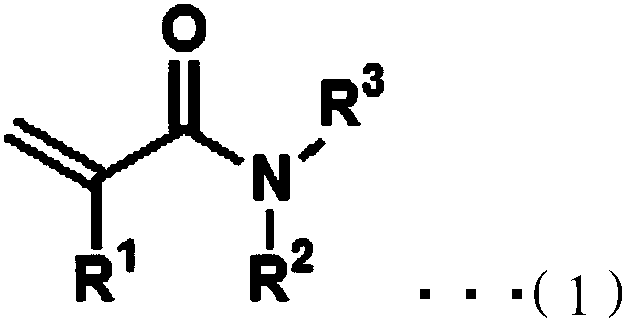

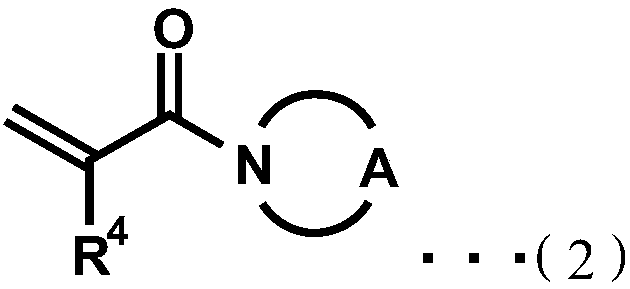

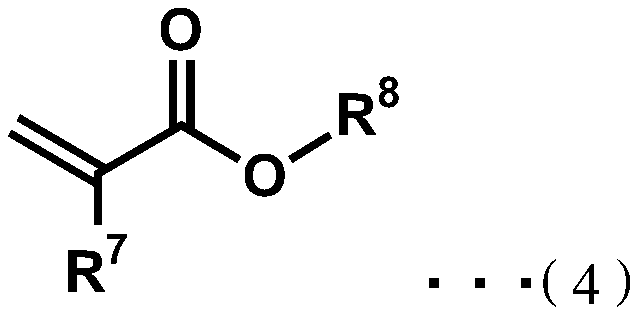

[0098] The copolymer (A) of the present invention is obtained by copolymerizing the monomer mixture. As the structure of the copolymer, it may be any structure of random copolymer, alternating copolymer, block copolymer and graft copolymer. From the viewpoint of the effect and the ease of preparation of the antifogging agent composition, a random copolymer is preferable. As the polymerization method for obtaining the copolymer, known various polymerization methods such as radical polymerization method, cationic polymerization method, anionic living polymerization method, cationic living polymerization method, etc. can be used, especially from the ease of industrial productivity, related From the viewpoint of various performances, the radical polymerization method is preferable. As the radical polymerization method, the usual bulk polymerization method, suspension polymerization method, solution polymerization method, emulsion polymerization method, etc. can be used...

Embodiment

[0144] Hereinafter, although an Example etc. demonstrate this invention, this invention is not limited to these.

[0145]

[0146]

[0147] 213 parts by weight of n-propanol as a polymerization solvent was put into a reaction container equipped with a thermometer, a stirring device, a nitrogen gas introduction pipe, and a cooling pipe, and nitrogen gas was blown thereinto, followed by heating to 80°C. Then, dropwise added over 2 hours: 35 parts by weight of N,N-dimethylacrylamide as monomer (A-1), 30 parts by weight of methyl methacrylate as monomer (A-2) and 20 parts by weight of butyl acrylate, 10 parts by weight of 2-hydroxyethyl acrylate as monomer (A-3), 5 parts by weight of N-methylolacrylamide as monomer (A-4), 15 parts by weight of n-propanol A solution mixed in parts by weight; and tert-hexyl peroxypivalate (manufactured by NOF Corporation, product name "Perhexyl PV" (active ingredient 70% by weight)) equivalent to 1.0 parts by weight as a radical polymerization i...

Embodiment 2~27

[0196]

[0197] Except having changed the monomer of Example 1 into the raw material and its ratio described in Tables 1-3, the solution of the copolymer (A) of Examples 2-27 was prepared by operation similar to Example 1.

[0198]

[0199] The antifogging composition of Examples 2-27 was prepared by the same operation as Example 1 except having changed the raw material of Example 1 into the raw material and its ratio described in Tables 1-3. Furthermore, by the same operation as Example 1, the antifogging article (test piece) which has the antifogging coating film of Examples 2-27 was produced.

[0200] Tables 1-3 show the results obtained by the evaluation methods of (1-1) to (1-4) and (2) to (4) above using the test pieces obtained above.

[0201]

[0202]

[0203] 223 parts by weight of n-propanol as a polymerization solvent and N,N-dimethylacrylamide (DMAA) as a monomer (A-1) were added to a reaction vessel equipped with a stirring device, a nitrogen gas introduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com