A kind of oven method of top-bottom double blowing converter

A technology of top-bottom re-blowing and oven method, applied in the direction of manufacturing converters, etc., can solve the problems of insufficient coke combustion, poor furnace bottom baking effect, furnace leakage accidents, etc., to achieve furnace body safety and improve furnace body safety. Maintenance effect, effect of improving oven quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: 120t top-bottom combined blowing converter, when opening a new furnace, the following method is used for drying.

[0031] The oven method of the top and bottom combined blowing converter, the steps are as follows:

[0032] 1. Preparation of raw materials. 10 tons of ordinary coke for ironmaking, one empty steel hopper, 500 kilograms of wood, and two long oxygen blowing pipes. Among them, 10 tons of coke is divided into two parts: 7 tons of coke is transported from the ground material warehouse to the upper converter high-level silo for process use, and 3 tons of coke is loaded into the scrap hopper.

[0033] 2. Ignite the coke in the scrap hopper in advance. Two hours before the oven, the coke in the waste steel hopper is ignited by firewood, and the combustion is supported by two oxygen blowing pipes. The coke is fully burned with oxygen in the waste steel hopper for 2 hours and then added to the converter.

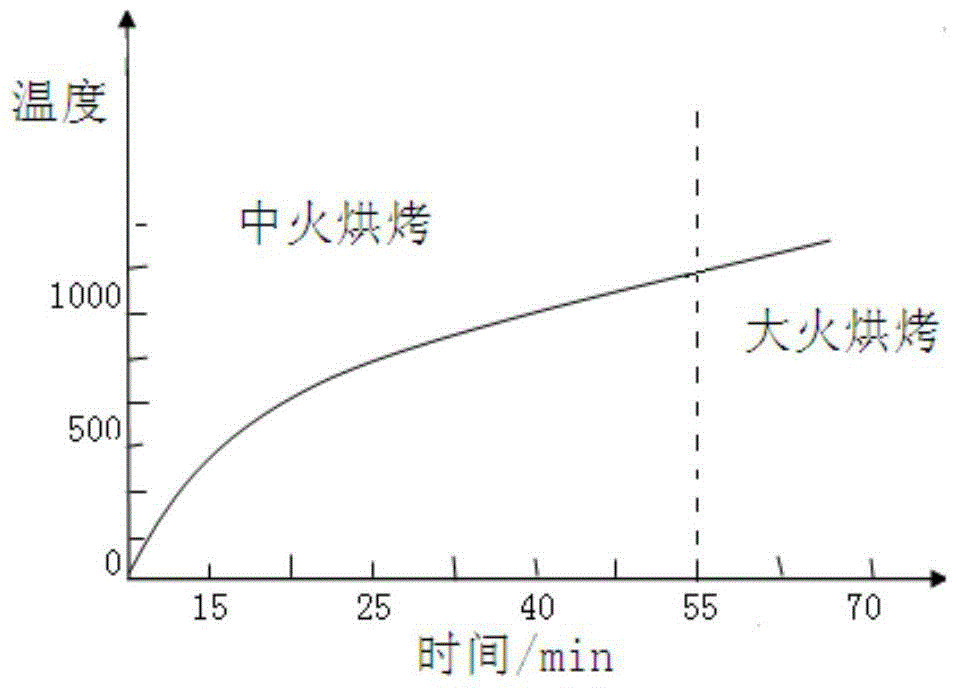

[0034] 3. Medium heat baking mode. The bottom blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com