Furnace baking method of bright annealing furnace

A furnace method and bright annealing technology, applied in the field of heat treatment, can solve the problems of refractory material deformation, unfavorable use of continuous annealing furnace, damage, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

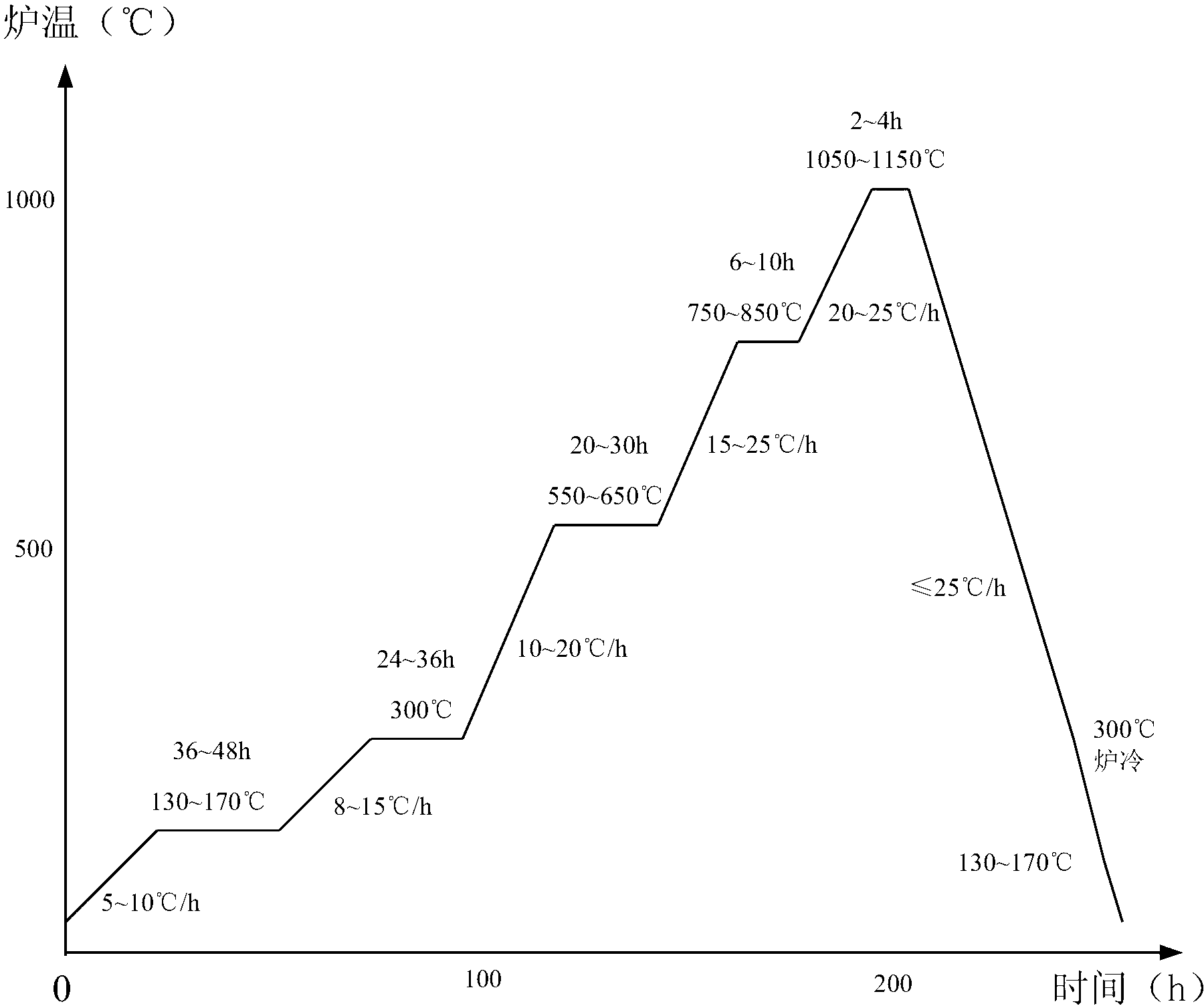

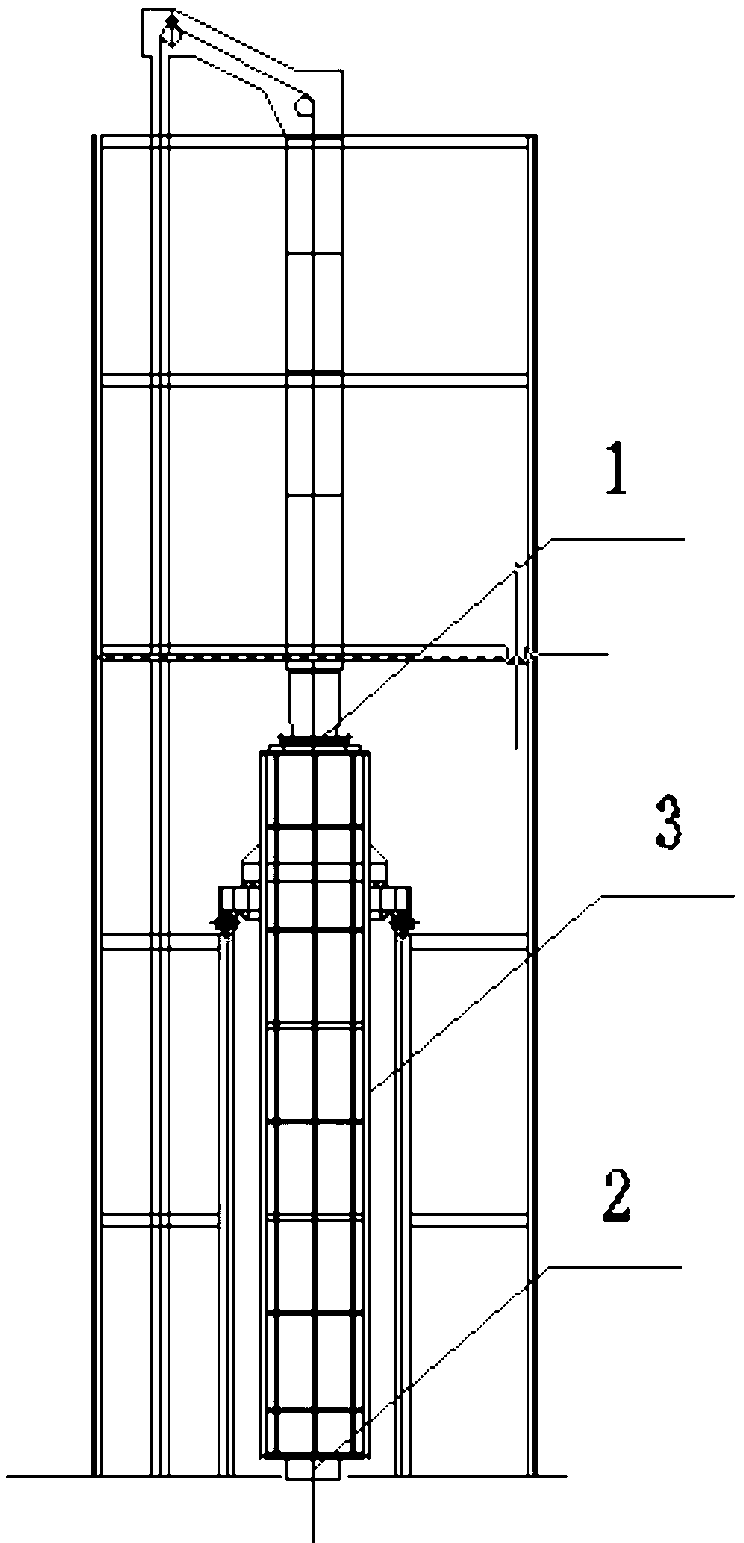

[0041] The annealing furnace in this embodiment is a vertical bright annealing furnace for producing stainless steel bright annealing plates, and a vertical muffle tube is arranged in the bright annealing furnace; after the annealing furnace is newly built, the furnace is baked according to the following process. The specific method of baking the annealing furnace is as follows:

[0042]First, start the cooling water; carry out the test run and inspection of the single equipment. Carry out a single test run for the power supply equipment, electric power adjustment system, temperature measuring instrument, etc. participating in the oven, and require the test run results to meet the functional requirements; require that the furnace lining and heating elements of the annealing furnace have been installed, and the inspection is qualified, and the heating The commissioning of the components has been completed and meets the functional requirements. Ensure that all turning rolls and...

Embodiment 2

[0051] The annealing furnace in this embodiment is a vertical bright annealing furnace for producing stainless steel bright annealing plates, and a vertical muffle tube is installed in the bright annealing furnace; after the annealing furnace is overhauled, if it needs to be heated again to prepare for production, the furnace is baked according to the following process. The specific method of baking the annealing furnace is as follows:

[0052] First, start the cooling water; carry out the test run and inspection of the single equipment. Carry out a single test run for the power supply equipment, electric power adjustment system, temperature measuring instrument, etc. participating in the oven, and require the test run results to meet the functional requirements; require that the furnace lining and heating elements of the annealing furnace have been installed, and the inspection is qualified, and the heating The commissioning of the components has been completed and meets the ...

Embodiment 3

[0062] The annealing furnace in this embodiment is a vertical bright annealing furnace for producing stainless steel bright annealing plates. The vertical muffle height in the bright annealing furnace is 2450 mm, and is divided into zones 1 to 8 from bottom to top. After the annealing furnace is overhauled, the temperature is raised again to prepare for production, and the furnace is baked according to the following process.

[0063] Start the cooling water; carry out the test run and inspection of the single equipment. Carry out a single test run of the power supply equipment, electric power adjustment system, temperature measuring instrument, etc. participating in the oven, and confirm that the test run results of the single equipment meet the functional requirements; check that the furnace lining and heating elements of the annealing furnace have been installed, and the inspection is qualified. The test run of the heating element has been completed and meets the functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com