Low-impact normally open high-pressure electric explosion valve

A normally open, high-voltage electric technology, applied in the field of aerospace engineering, can solve the problems of reducing the reliability of work and sealing, the influence of the sealing performance of the pipeline system, and the complex structure of the electric explosion valve, so as to achieve small impact in place and safe and reliable work. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

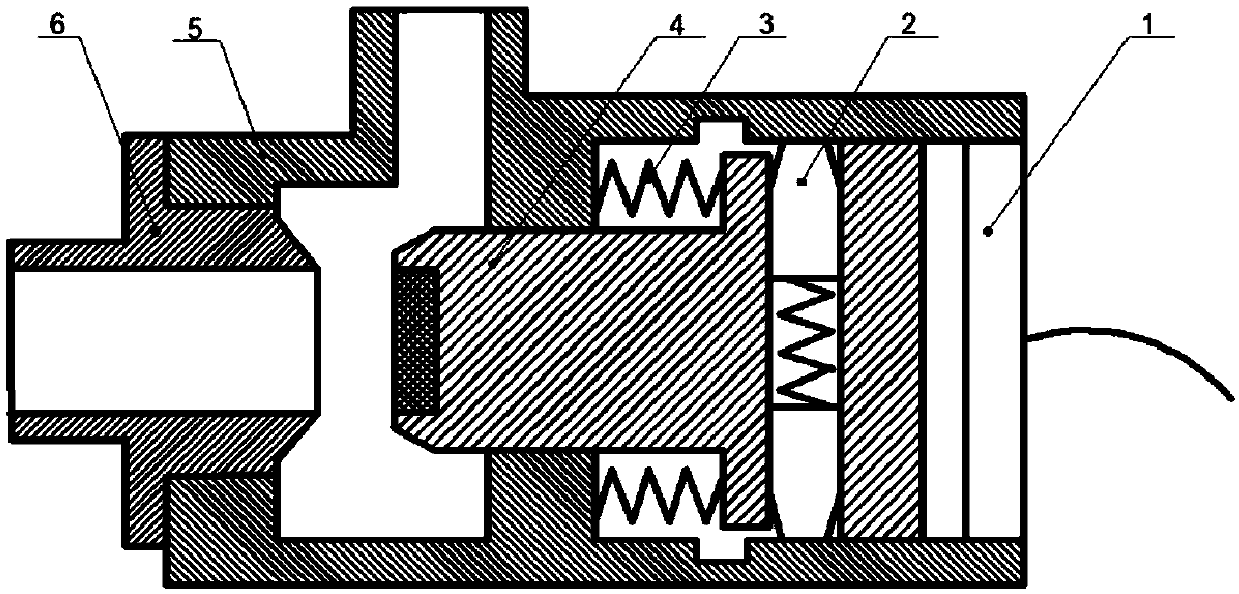

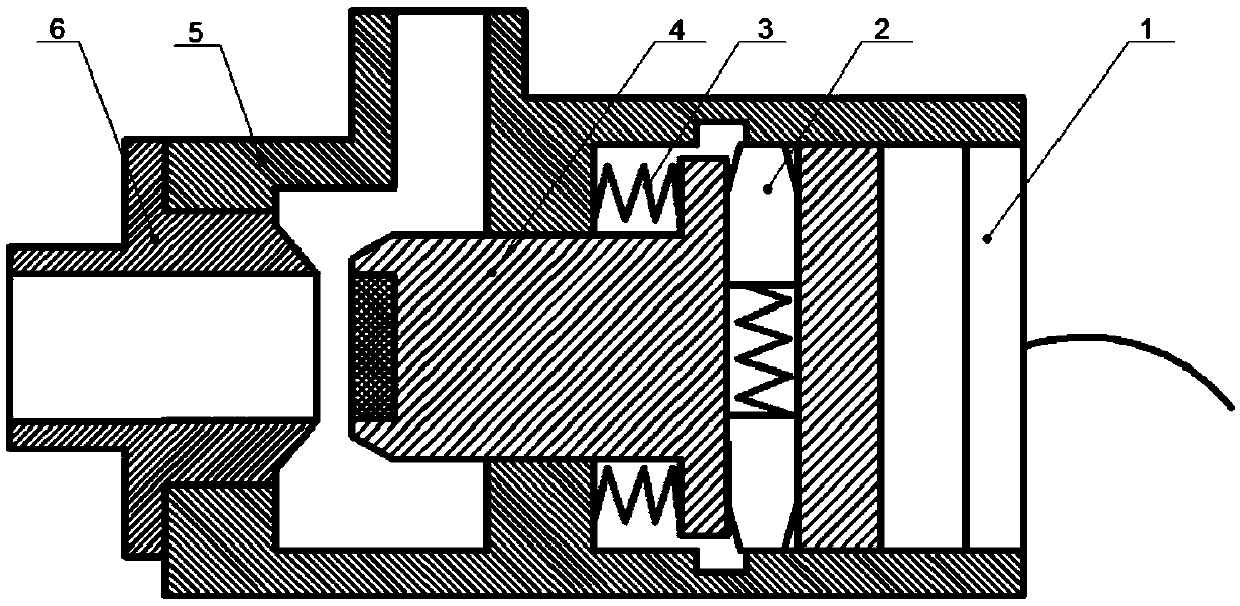

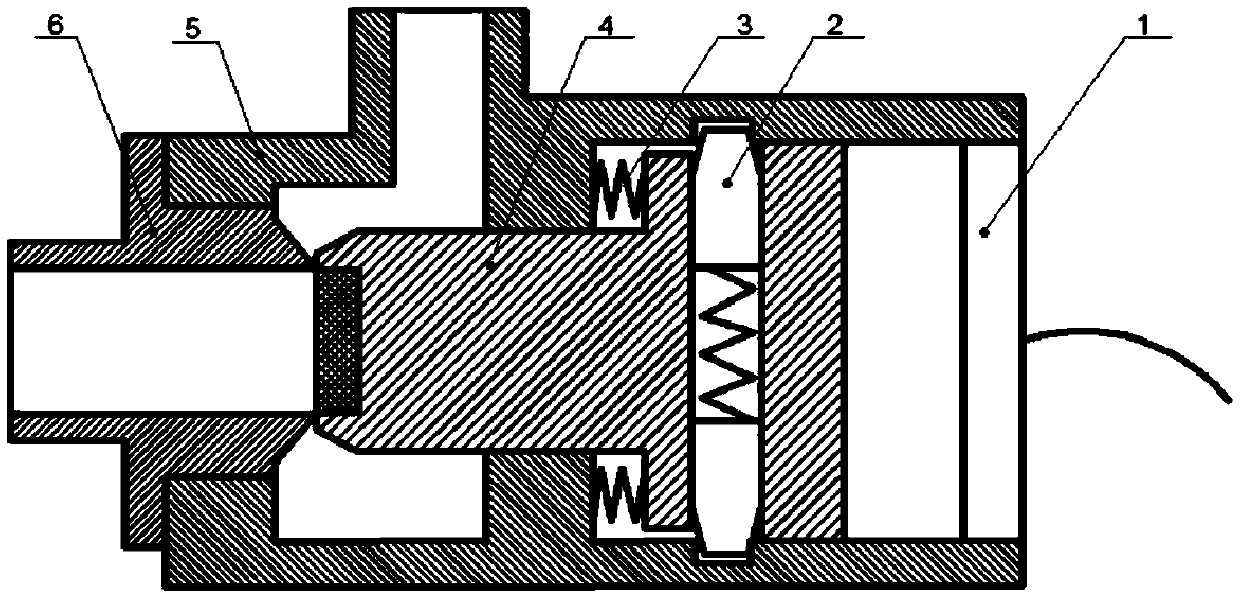

[0022] This embodiment provides a low-impact normally open high-voltage electric explosion valve, which is used for the flow control of high-pressure gas in the pipeline system, such as figure 1 As shown, it includes a valve seat 6, a valve body 5, a valve 4, a locking spring 3, a locking pin 2 and an electric detonator 1.

[0023] The valve body 5 has a three-way structure, one port is set on the side, and is connected to the external pipeline through a pipe joint as an outlet, and the other two ports are coaxially arranged, and one port is connected to the valve seat 6, and the valve seat 6 is connected to the external pipeline as an outlet. The inlet and the other port are fixedly connected with the electric detonator 1 , and the inner circumference of the valve body 5 is provided with a circumferential boss matched with the valve 4 .

[0024] The valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com