Corrosion inhibitors and corrosion inhibitor compositions, and preparation methods thereof, application of corrosion inhibitors and corrosion inhibitor compositions to inhibition of aqueous corrosion, and treating method for circulating water

A kind of technology of corrosion inhibitor and composition, applied in corrosion inhibitor composition, preparation of the foregoing corrosion inhibitor, corrosion inhibitor, application of the foregoing corrosion inhibitor or the foregoing corrosion inhibitor composition in inhibiting water corrosion, circulation In the field of water treatment, it can solve problems such as unfavorable cooling water recycling, and achieve the effect of being difficult to be used by microorganisms, lasting drug effect and good corrosion inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

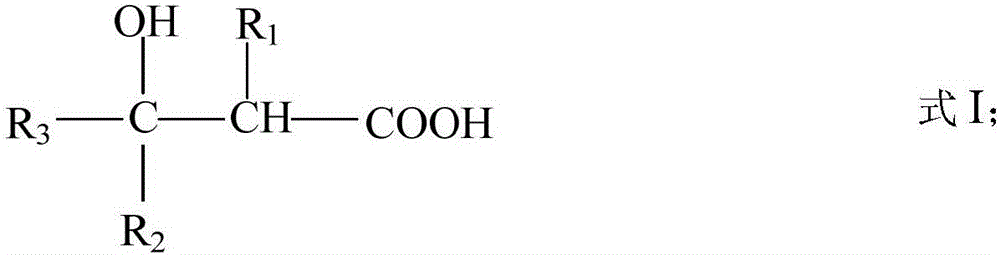

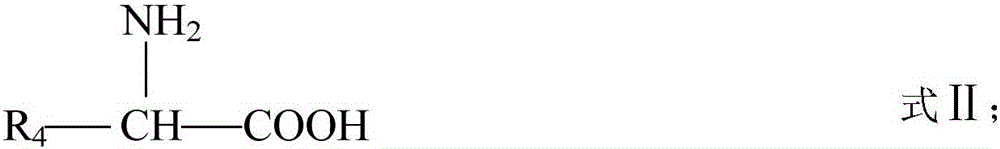

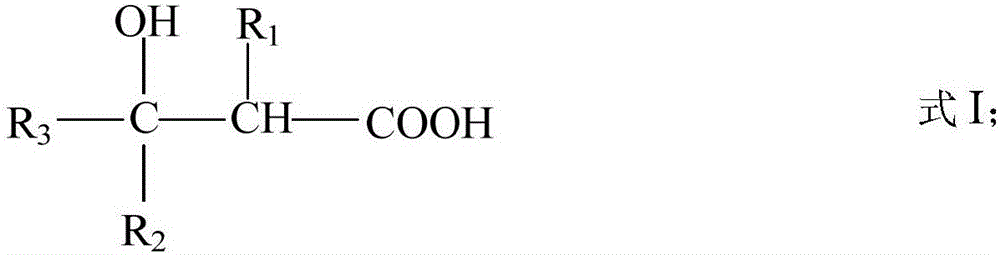

[0043] At the same time, the present invention also provides a preparation method of a corrosion inhibitor, the preparation method comprising: contacting an aliphatic hydroxycarboxylic acid and / or its salt with an amino acid in water under condensation reaction conditions and in the presence of a catalyst to form The corrosion inhibitor; wherein, the aliphatic hydroxycarboxylic acid has the structure shown in the following formula I; the amino acid has the structure shown in the following formula II,

[0044]

[0045]

[0046] In the formula I, R 1 is H or OH, R 2 for H or COOH, R 3 for COOH, CH 2 -COOH or In the formula II, R 4 for H, C 1 -C 4 Alkyl, (CH 2 ) n -COOH,CH 2 ) 4 -NH 2 , or CH 2 -OH, wherein n and m are each independently selected from 1 and 2.

[0047] The preparation method of the corrosion inhibitor provided by the present invention forms a water-soluble condensation reaction product by promoting the condensation reaction of the alip...

preparation example 1

[0087] Add 21.8g (0.1mol) of sodium gluconate, 26.6g (0.2mol) of aspartic acid, and 100ml of water into a four-necked flask equipped with a stirrer, a distillation device, and a thermometer, and start stirring to make sodium gluconate and asparagus The acid was fully dissolved and mixed, and then 15.0 g of concentrated sulfuric acid (containing H 2 SO 4 0.15mol). Heat the heating bath (the heating medium is simethicone oil) with the aforementioned flask built in to 100°C, and react for 10 hours. During the reaction, the amount of water evaporated is 30g, and the remaining liquid is cooled to obtain the corrosion inhibitor. This product is designated as S1, It is determined that the solid content of the corrosion inhibitor S1 is 29.5% by weight, and the molecular weight distribution of the condensation reaction product in the corrosion inhibitor S1 is determined to be in the range of 311-426.

preparation example 2-5

[0089] The preparation method of corrosion inhibitor: refer to the preparation method of corrosion inhibitor in Preparation Example 1, the difference is that the consumption of each raw material is different, and the specific content is shown in the following table:

[0090] Preparation example

[0091] The corrosion inhibitors prepared in Preparation Examples 2-5 are designated as S2-S5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com