Method for preparing steel structure aqueous corrosion-resistant fireproof coating material

A fire-resistant coating and steel structure technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of discontinuous fire-proof carbon layer, limit the flame-retardant efficiency of P-N flame retardants, etc., achieve simple construction and eliminate microscopic corrosion , avoid the effect of re-stacking and aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with examples.

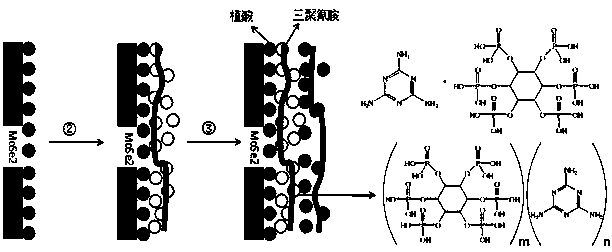

[0027] (1) Preparation of functionalized MoSe2 nanosheets: Melamine and phytic acid were prepared into 0.05wt% and 1wt% solutions, respectively.

[0028] ① Dissolve phytic acid in a solution of ethanol and water (ethanol: water = 95:5) at room temperature to form a mixed solution with a concentration of 2g / L. At room temperature, the MoSe2 nanosheets were soaked in this solution, and after 2 hours, the solution was centrifuged three times with a centrifuge, rinsed three times with deionized water, and finally dried with nitrogen for later use.

[0029] ② Put the above-mentioned MoSe2 nanosheets in the prepared melamine solution for 30 minutes, centrifuge the solution 3 times in a centrifuge, rinse 3 times with distilled water, and blow dry with nitrogen;

[0030] ③ Put the melamine-adsorbed MoSe2 nanosheets in the prepared phytic acid solution for 30 minutes, centrifuge the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com