Preparation method of aqueous corrosion-resistant dendritic-crystal-free metal negative electrode

A metal negative electrode and corrosion-resistant technology, which is applied in the field of energy storage, can solve the problems of reducing the utilization rate of metal negative electrodes, reducing the utilization rate of metal negative electrodes, and corrosion of metal negative electrodes, so as to reduce local current density, reduce deposition overpotential, and reduce side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing an aqueous corrosion-resistant, dendrite-free metal negative electrode, which at least includes the following steps:

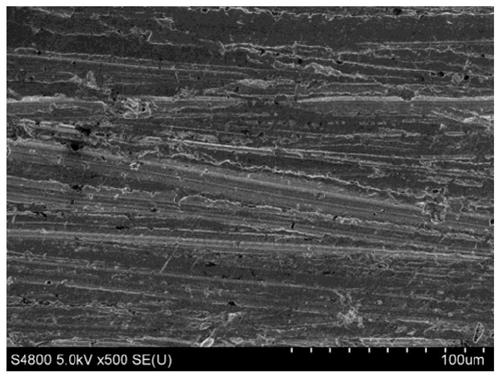

[0039] The first step, active metal sheet pretreatment: the dense zinc metal sheet is polished with 10-500 mesh sandpaper to remove impurities, and then washed three times with inert gas-saturated deionized water for a total of 1000s. Carry out natural drying to obtain the pretreated zinc metal sheet, and then cut the pretreated zinc metal sheet into zinc metal sheets of different sizes for use; the thickness of the zinc metal sheet is 0.001mm-50mm; the size is 2mm-50m .

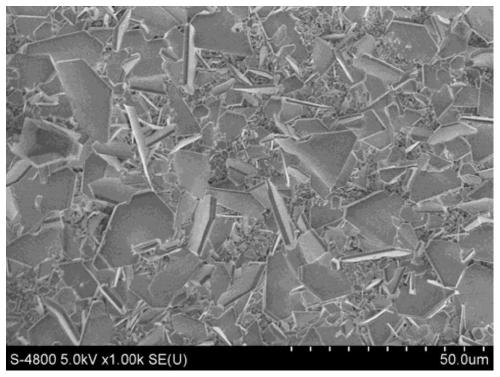

[0040] In the second step, the chemical deposition method is used to dissolve the halide salt (indium chloride) of the inactive metal indium in deionized water, stir well, and the stirring temperature is 40 ° C, and prepare a 0.1mol / L indium chloride aqueous solution. Then soak the pretreated and cut zinc metal sheet obtained in the fir...

Embodiment 2

[0044] This embodiment provides a method for preparing an aqueous corrosion-resistant, dendrite-free metal negative electrode, which at least includes the following steps:

[0045] The first step, active metal sheet pretreatment: the dense zinc metal sheet is polished with 10-500 mesh sandpaper to remove impurities, and then washed twice with dilute sulfuric acid with a concentration of 1.5mmol / L. The total treatment time is 1500s, and then Carry out natural drying at room temperature, obtain the zinc metal sheet after the pretreatment, then the zinc metal sheet after the pretreatment is cut into the zinc metal sheet of different sizes for use; The thickness of the zinc metal sheet is 0.001mm-50mm; The size is 2mm-50m.

[0046] In the second step, the chemical deposition method is used to dissolve the halide salt (indium chloride) of inactive metal indium in deionized water, stir well, and the stirring temperature is 50 ° C, and prepare a 0.5mol / L indium chloride aqueous solut...

Embodiment 3

[0049] This embodiment provides a method for preparing an aqueous corrosion-resistant, dendrite-free metal negative electrode, which at least includes the following steps:

[0050] The first step, active metal sheet pretreatment: the dense zinc metal sheet is polished with 10-500 mesh sandpaper to remove impurities, and then washed four times with dilute acetic acid and acetone with a concentration of 1.5mmol / L. The total processing time is 2500s, then blow dry at room temperature to obtain the pretreated zinc metal sheet, then cut the pretreated zinc metal sheet into zinc metal sheets of different sizes for use; the thickness of the zinc metal sheet is 0.001mm-50mm; the size 2mm-50m.

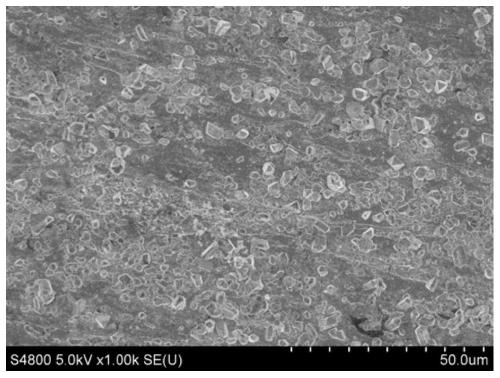

[0051] In the second step, the method of chemical deposition is adopted to dissolve the salt of inactive metal copper (copper sulfate) in deionized water, stir fully, the stirring temperature is 30°C, and prepare a 0.1mol / L copper sulfate aqueous solution, and then the first The zinc metal she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com