Underwater screw propulsion die and underwater navigation device containing the same

A propeller and reducer technology, which is applied to underwater ships, transportation and packaging, and underwater operation equipment, etc., can solve the problems of transmission efficiency affected by seawater pressure, frictional resistance, large volume and weight, etc., and achieve compact structure, Avoid frictional resistance and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

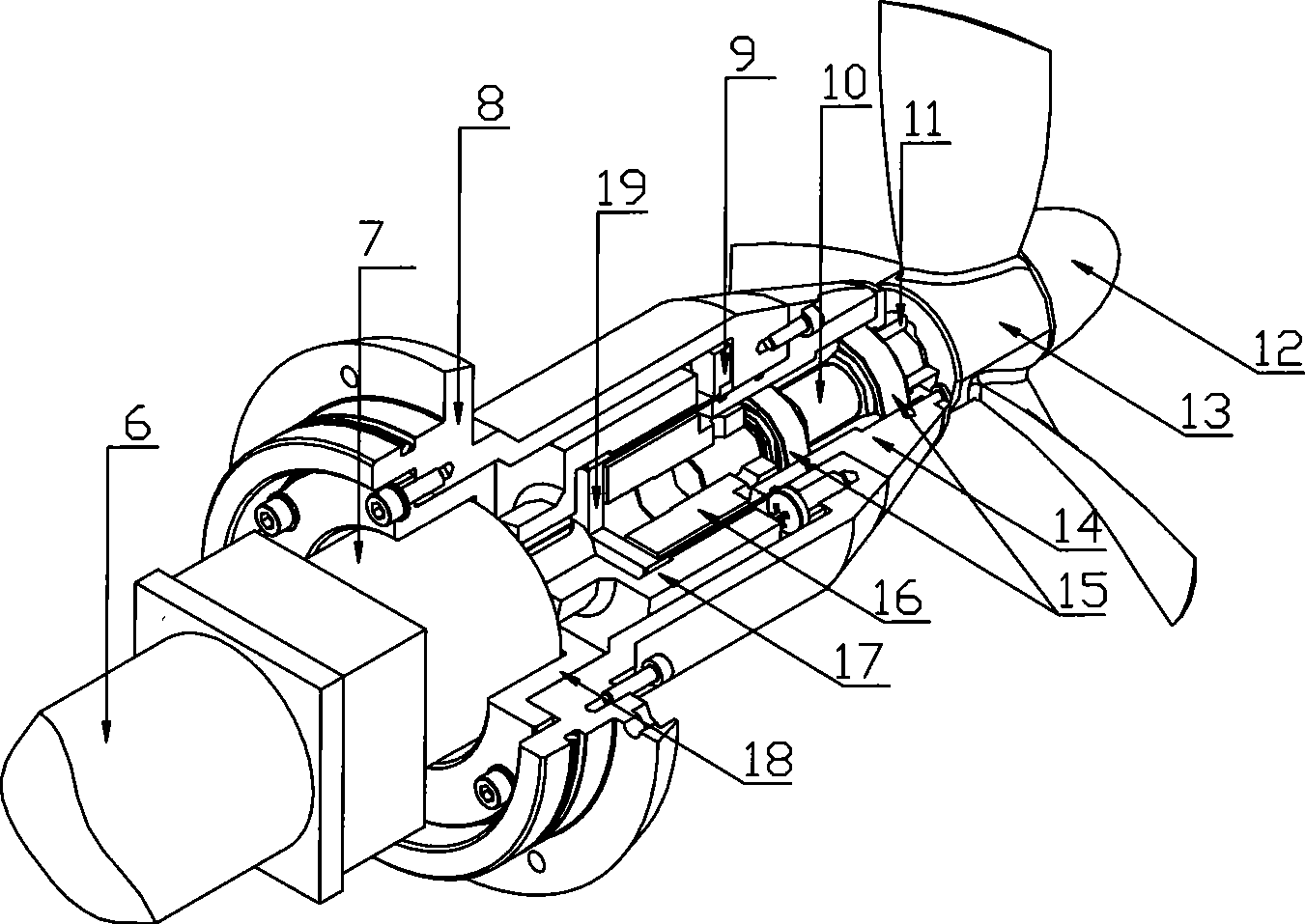

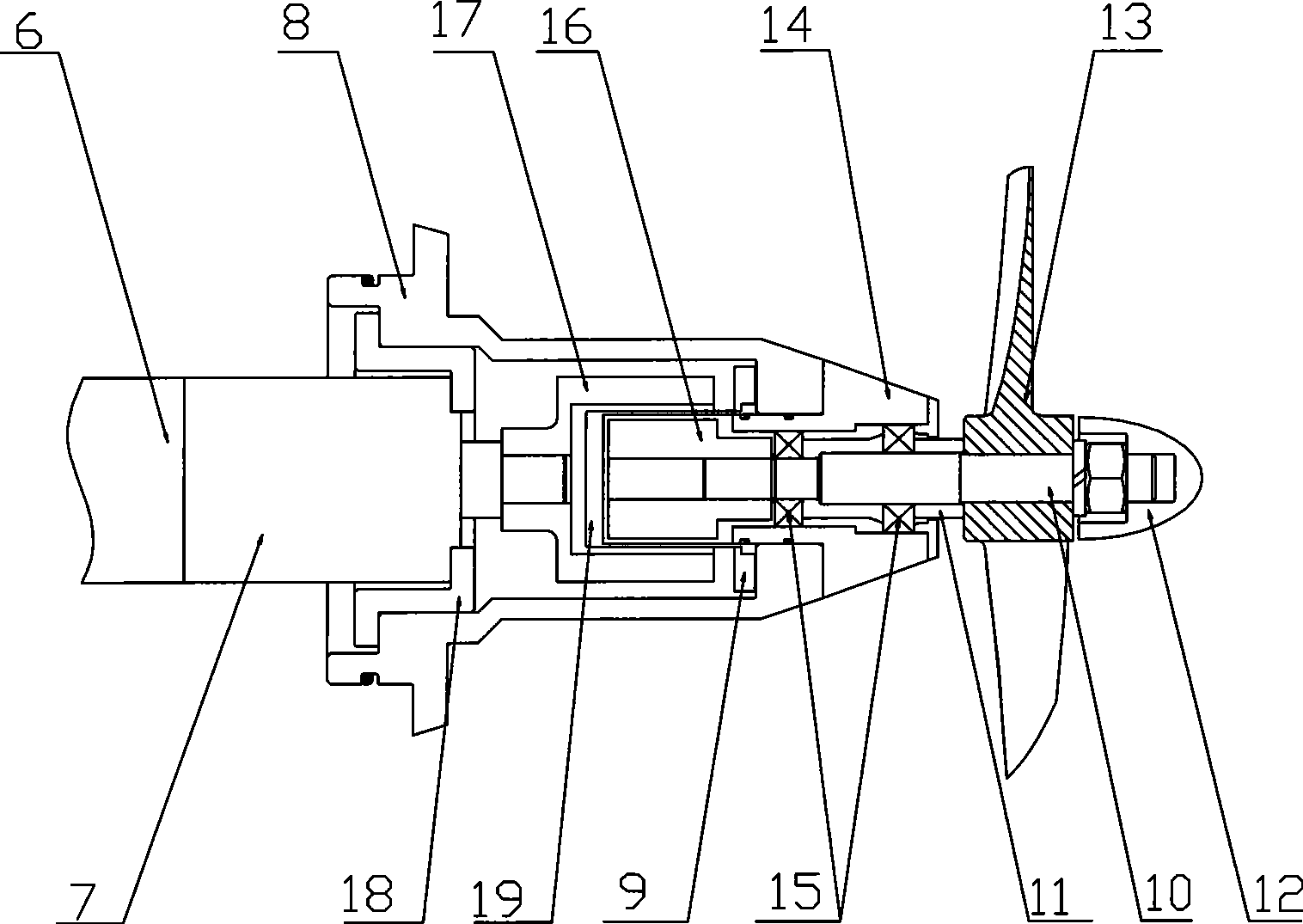

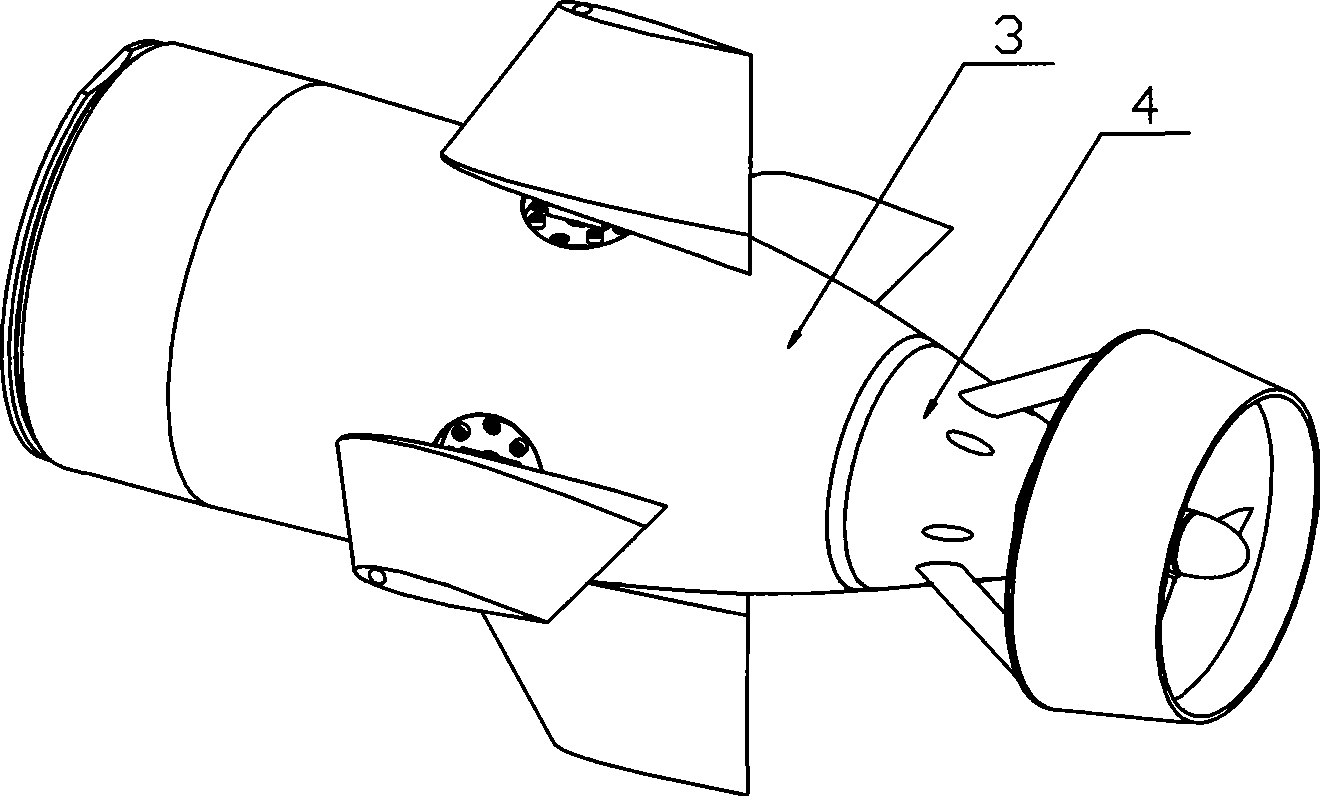

[0016] see figure 1 , figure 2 with image 3 , an underwater propeller propulsion module, including a motor 6 and a reducer 7 fixedly connected to the outer hub bracket 18, the reducer 7 is connected to the driven shaft 10 through a magnetic coupling in the tail cone, and the magnetic coupling is formed by an inner The hub 16, the outer hub 17 set outside the inner hub 16, the isolation cover 19 arranged between the inner hub 16 and the outer hub 17, and the compression ring 9 affixed to the isolation cover 19 are composed of the outer hub bracket 18 and the tail cone 8 is fixedly connected, the outer hub 17 is connected with the output shaft of the reducer 7 through a flat key and a set stud; the compression ring 9 is fixedly installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com