Spiral grid anti-seize seal structure

A technology with sealing structure and anti-jamming, applied in the field of sampling and detection, can solve the problems affecting the success or failure of tasks, encroachment of gaps, economic losses, etc., and achieve the effect of improving drilling safety, good sealing characteristics, and insensitive sealing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

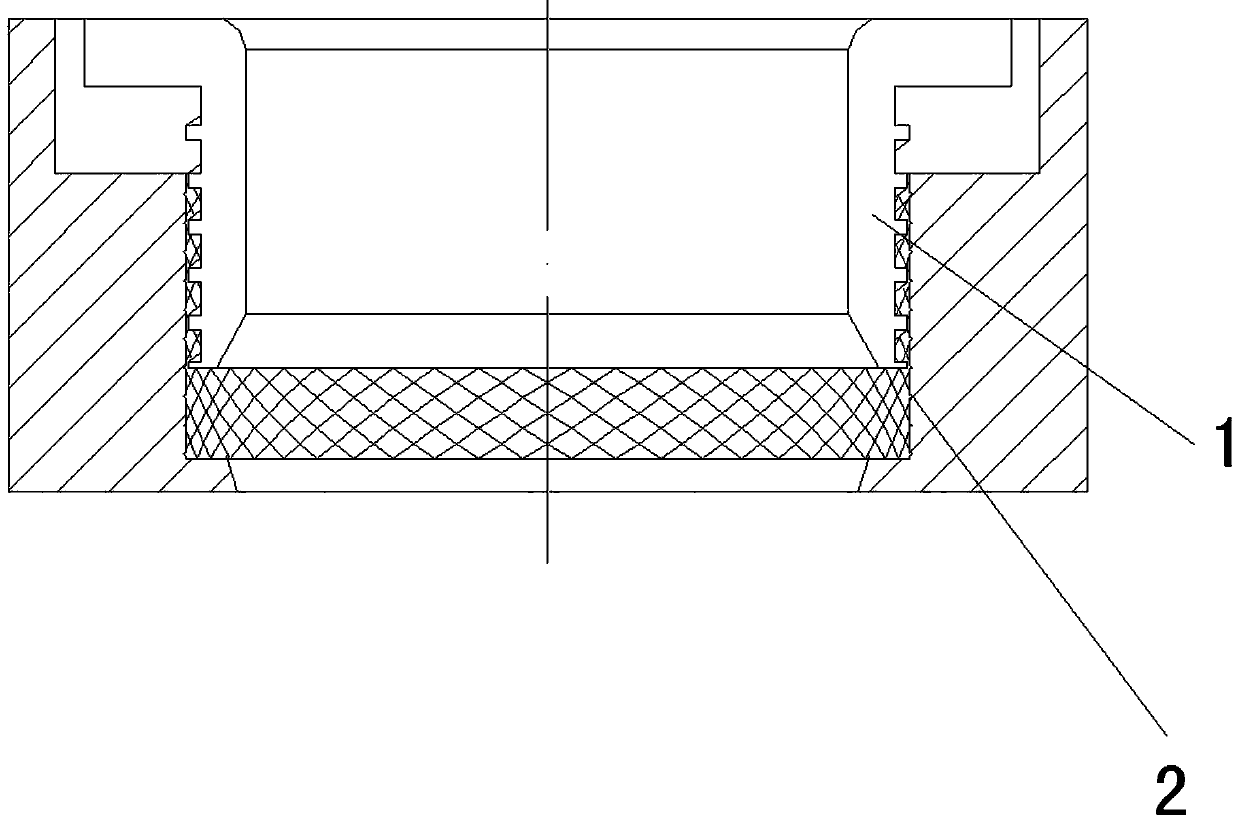

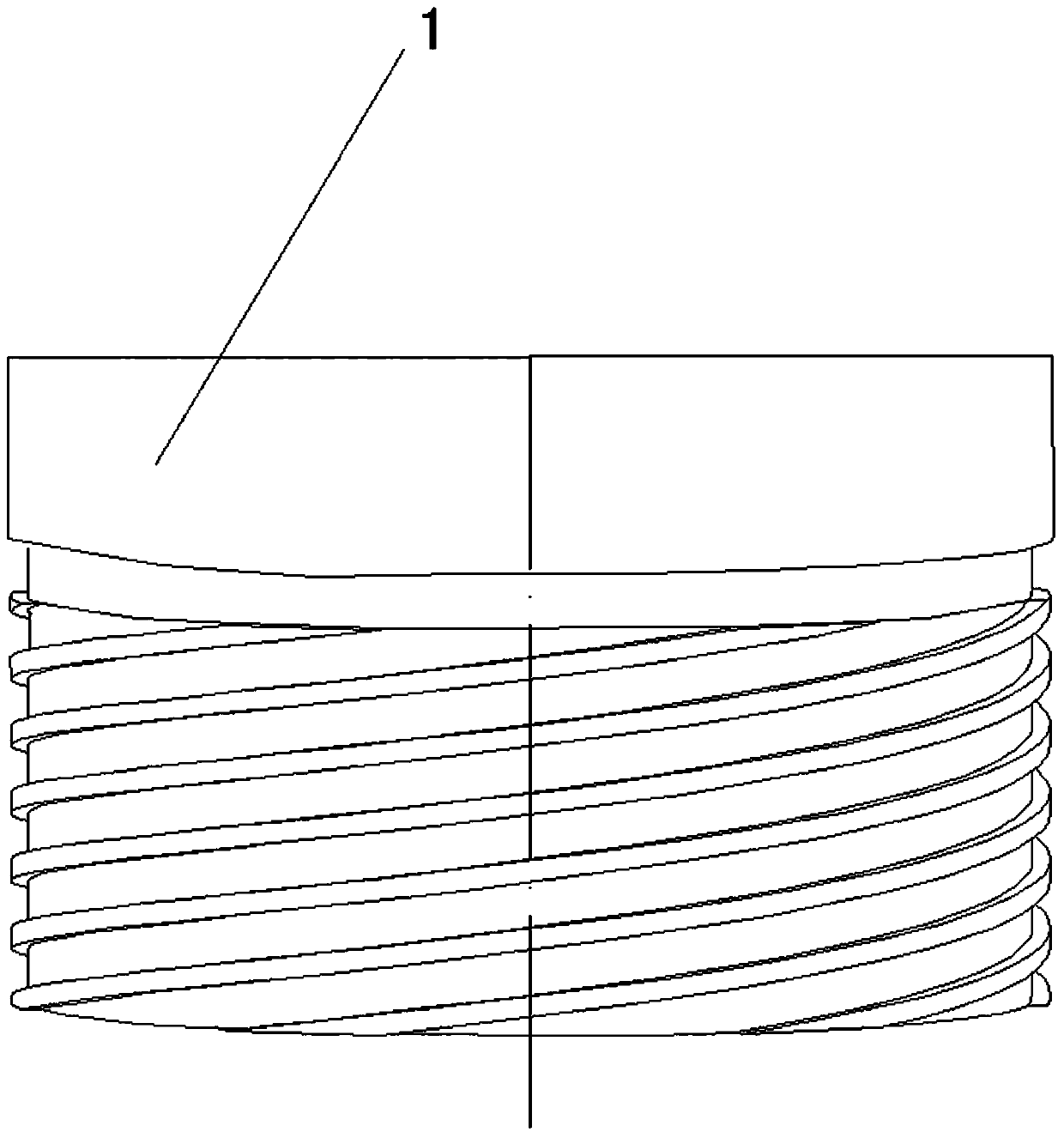

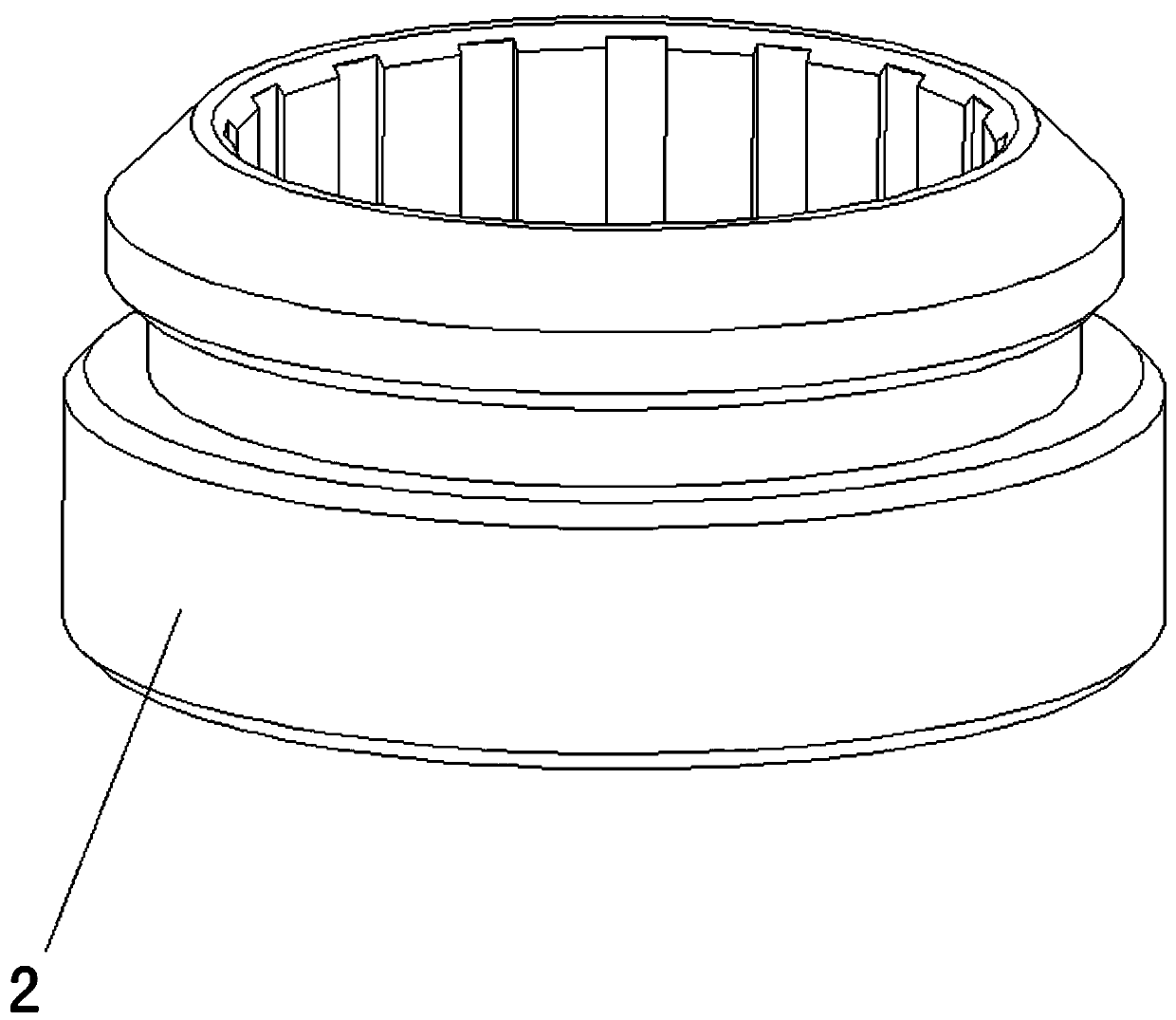

[0015] Such as Figure 1~Figure 4 As shown, the anti-jamming sealing structure in spiral grid format includes: the sampling outer protective tube shaft end 1 and the coring bit end 2, the coring bit end 2 is a hollow structure, and the coring bit end 2 is provided with a sampling outer protective tube The shaft end 1, the coring bit end 2 and the sampling outer protection tube shaft end 1 are slidingly matched, the outer surface of the sampling outer protection tube shaft end 1 is processed with threads, and the inner surface of the coring bit end 2 is processed with grooves to form The grid, or the inner surface of the core bit end 2 is processed with knurling.

[0016] There is a gap of 0.05-0.2 mm between the large diameter of the thread on the outer surface of the outer surface of the outer protective tube shaft end 1 of the sampling tube and the inner diameter of the grid on the inner surface of the core bit end 2, or the outer surface of the outer protective tube axial e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com