Patents

Literature

52results about How to "Improve drilling safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

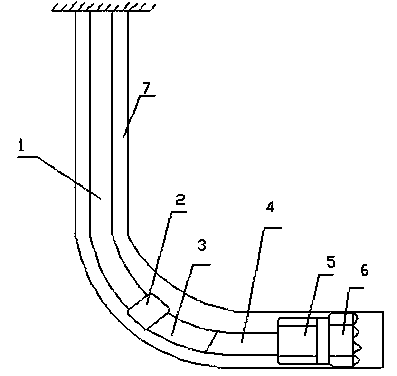

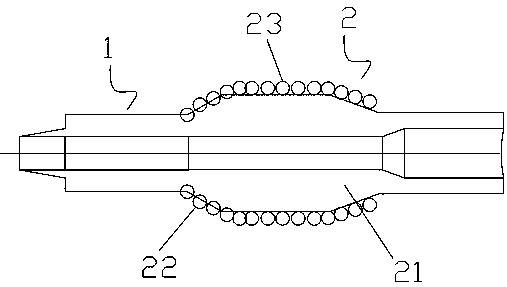

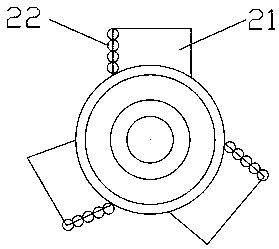

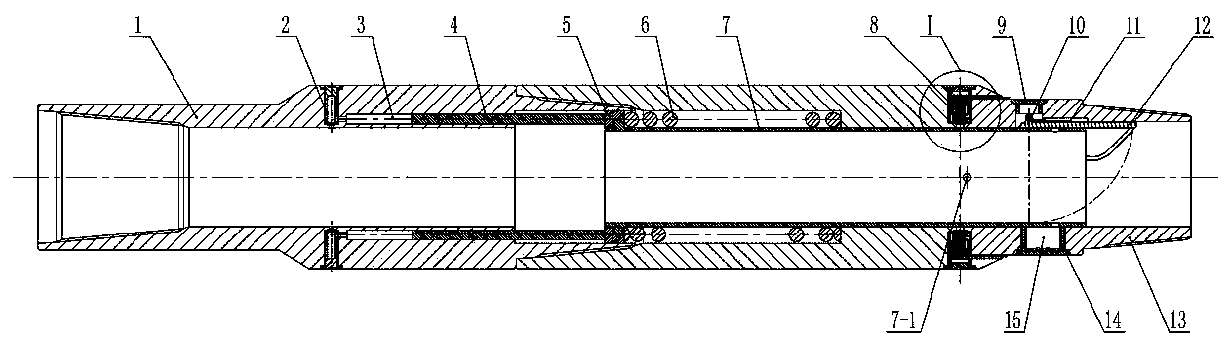

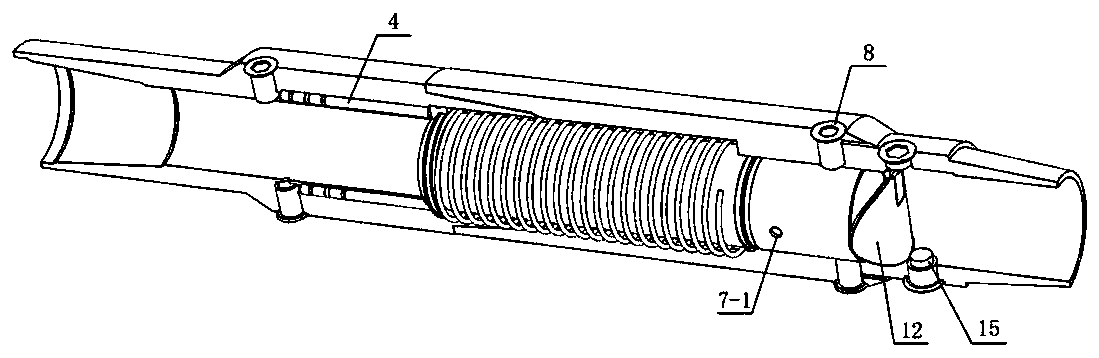

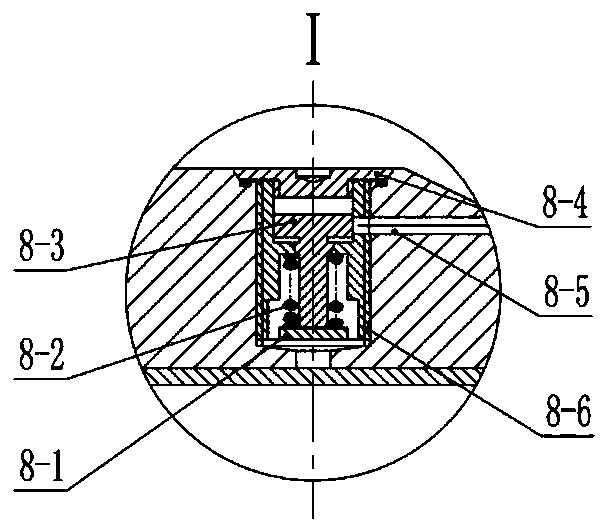

Complex structural well drag-reduction wrenching-reduction compound drilling method

ActiveCN103510871AReduce frictional torqueReduce drilling riskDrilling rodsDirectional drillingPetroleum engineeringDrill bit

The invention discloses a complex structural well drag-reduction wrenching-reduction compound drilling method. An underground drag-reduction wrenching-reduction device is arranged between an upper-portion drilling rig and a measurement-while-drilling drilling assembly combination, and therefore the upper-portion drilling rig can rotate independently relative to the measurement-while-drilling drilling rig; a reaction torque balancing device is arranged between a power drilling rig and a drill bit, and the disturbance of the reaction torque generated by a power drilling rig to a tool face is eliminated. The complex structural well drag-reduction wrenching-reduction compound drilling method has the advantages that the drag-reduction wrenching-reduction device can change the drill string sliding drilling into rotary drilling during the guiding drilling process, the friction resistance and the torque loss are reduced, and the occurrence rate of complex situations that the drill string is stuck and clamped is reduced; the reaction torque balancing device can effectively eliminate the influence of the reaction torque generated by a power drilling rig on the tool face, the tool face is controlled to be stable, the well track control accuracy is improved, the well body quality is improved, and complex structure well efficient drilling is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

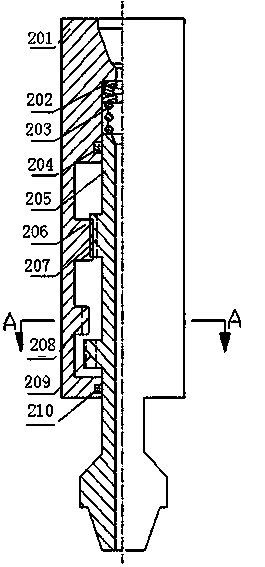

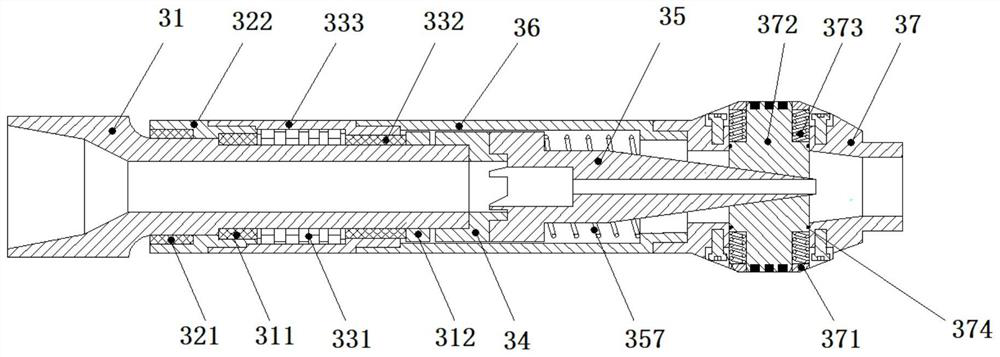

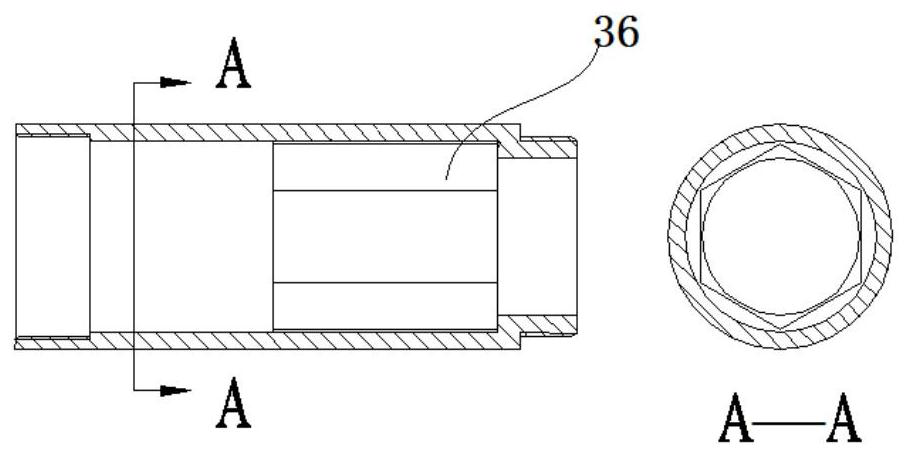

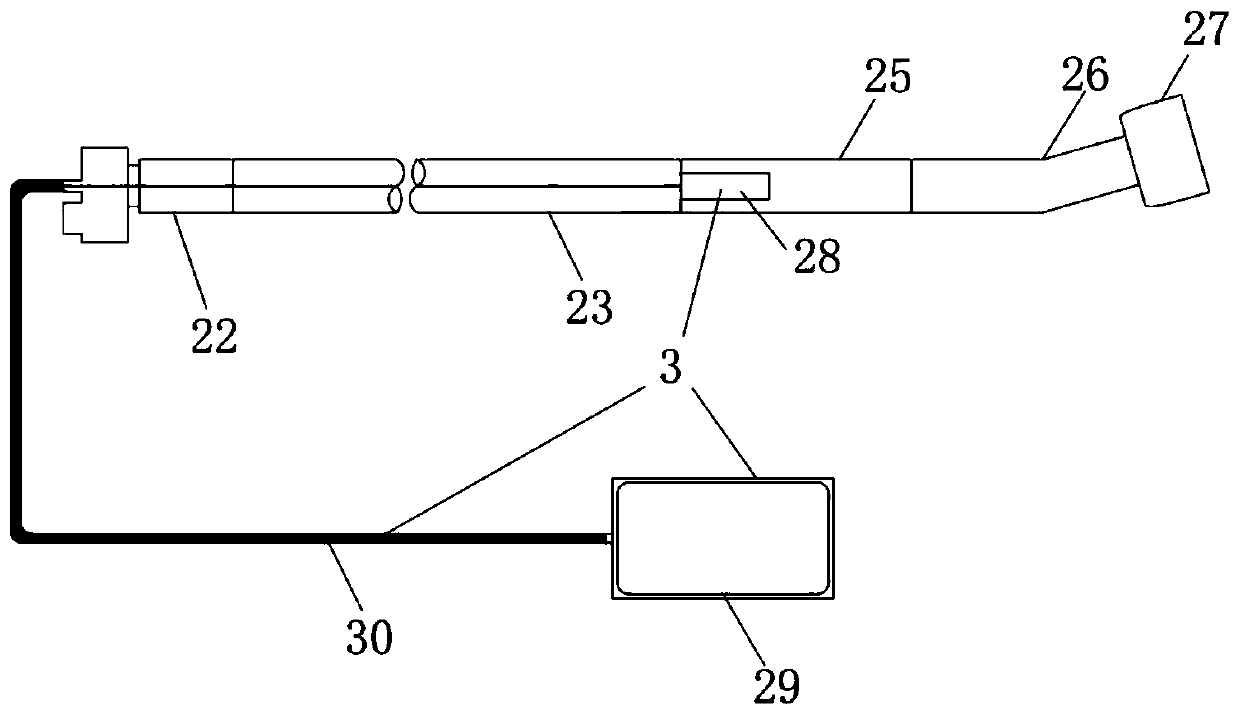

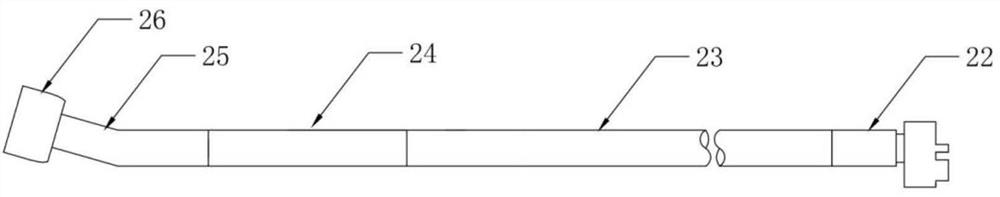

Underground coal mine directional drilling and reaming integrated drilling tool and directional drilling and reaming-while-drilling method

ActiveCN113107364AReduce torqueReduce loadDrill bitsDirectional drillingPilot holeMining engineering

The invention discloses an underground coal mine directional drilling and reaming integrated drilling tool and a directional drilling and reaming-while-drilling method, the directional drilling and reaming integrated drilling tool comprises a sliding directional drilling tool, a drilling state switching device and a rotary reaming drilling tool, and during directional drilling and reaming-while-drilling, the drilling state switching device adjusts the working state of the sliding directional drilling tool and the deflecting drilling direction. The sliding directional drilling tool conducts directional deflecting drilling under the action of feeding power provided by the drilling machine and rotation power provided by the single-bend screw motor, and a directional pilot hole is formed. The rotary reaming drilling tool performs reaming along the directional pilot hole under the action of feeding power and rotation power provided by the drilling machine, and large-diameter reaming while drilling is achieved. According to the method, the problems of small primary hole forming diameter, low secondary large-diameter reaming efficiency and difficulty in hole forming of complex broken stratums of current underground coal mine directional drilling are solved, large-diameter primary hole forming is realized, the range of stratums applicable to directional drilling is widened, the gas extraction effect is improved, and safe and efficient mining of a working face is ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

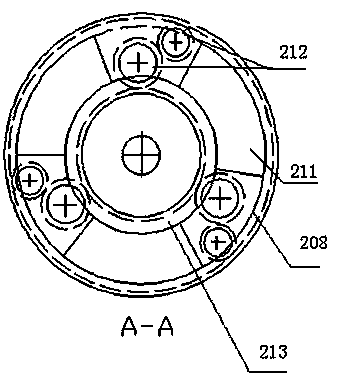

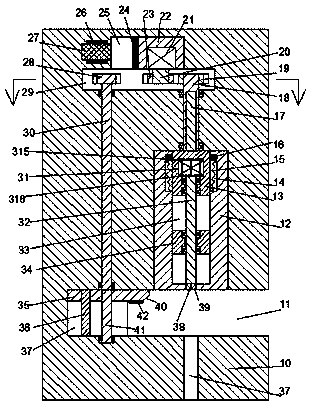

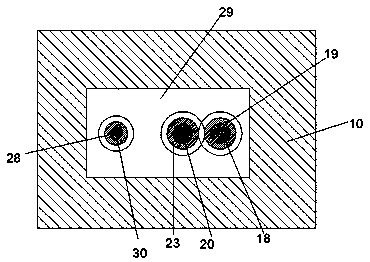

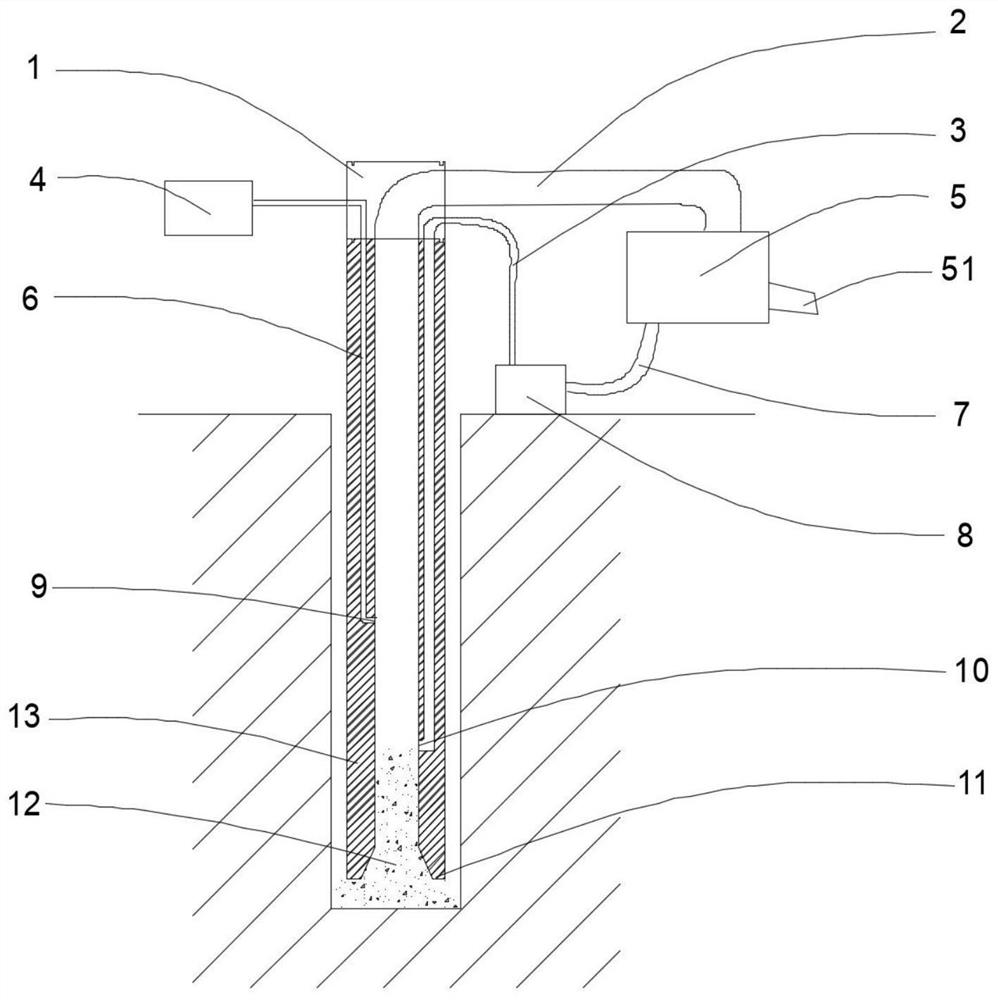

Coal mine underground complex fractured formation nearly-horizontal pressurizing and directional drilling device and method

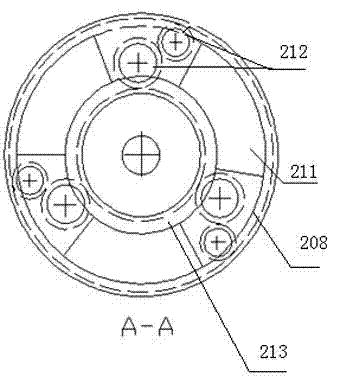

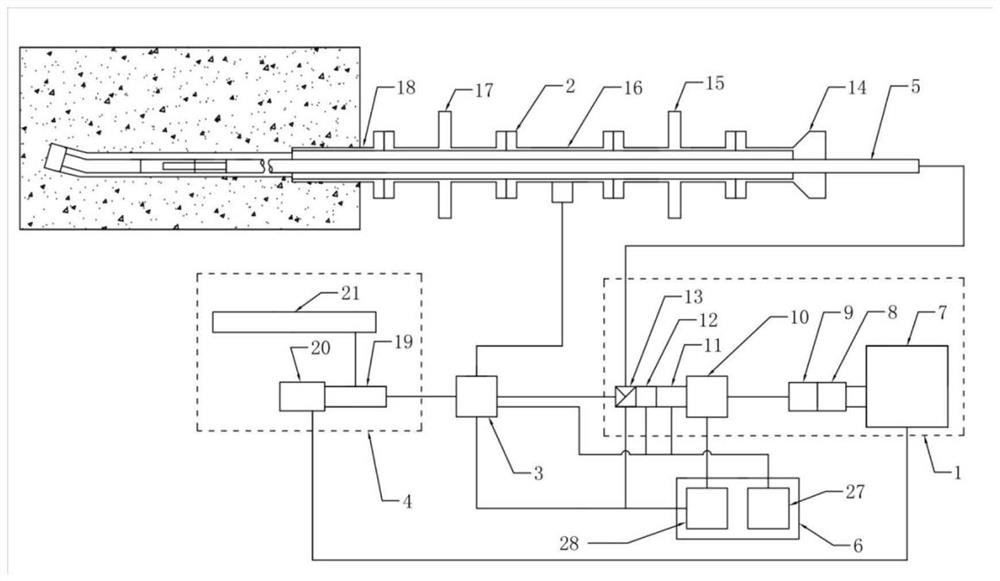

ActiveCN111502545AImprove hole wall stabilitySolve the key technical problems of pressurized drillingDrill bitsConstructionsMining engineeringUnderground tunnel

The invention relates to a coal mine underground tunnel drilling method, in particular to a coal mine underground complex fractured formation nearly-horizontal pressurizing and directional drilling device and method. The coal mine underground complex fractured formation nearly-horizontal pressurizing and directional drilling device comprises an orifice sleeve pipe for sealing an orifice during construction, a directional drilling tool assembly penetrating through the orifice sleeve pipe so as to enter a coal bed during construction, and a throttling and pressurizing system connected with a first fluid passageway formed between the directional drilling tool assembly and the orifice sleeve pipe, wherein a drilling tool center hole for one-way conducting is formed in the directional drillingtool assembly; and the throttling and pressurizing system can recover and input a fluid through the first fluid passageway. According to the coal mine underground complex fractured formation nearly-horizontal pressurizing and directional drilling device and method provided by the invention, a high-pressure flushing fluid is provided for a drill hole, and the pressure magnitude of the flushing fluid is controlled, so that a radial additional support force on the hole wall through the flushing fluid is larger than a balance pressure value of the hole wall, the drill hole is ensured to keep stable, the problems that the complex fractured formation drill hole is easy in instable failure and the safety accidents are occurred frequently are solved, and the hole forming rate and the constructionsafety of various coal mine underground nearly horizontal geological exploration and disaster prevention drilling are improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

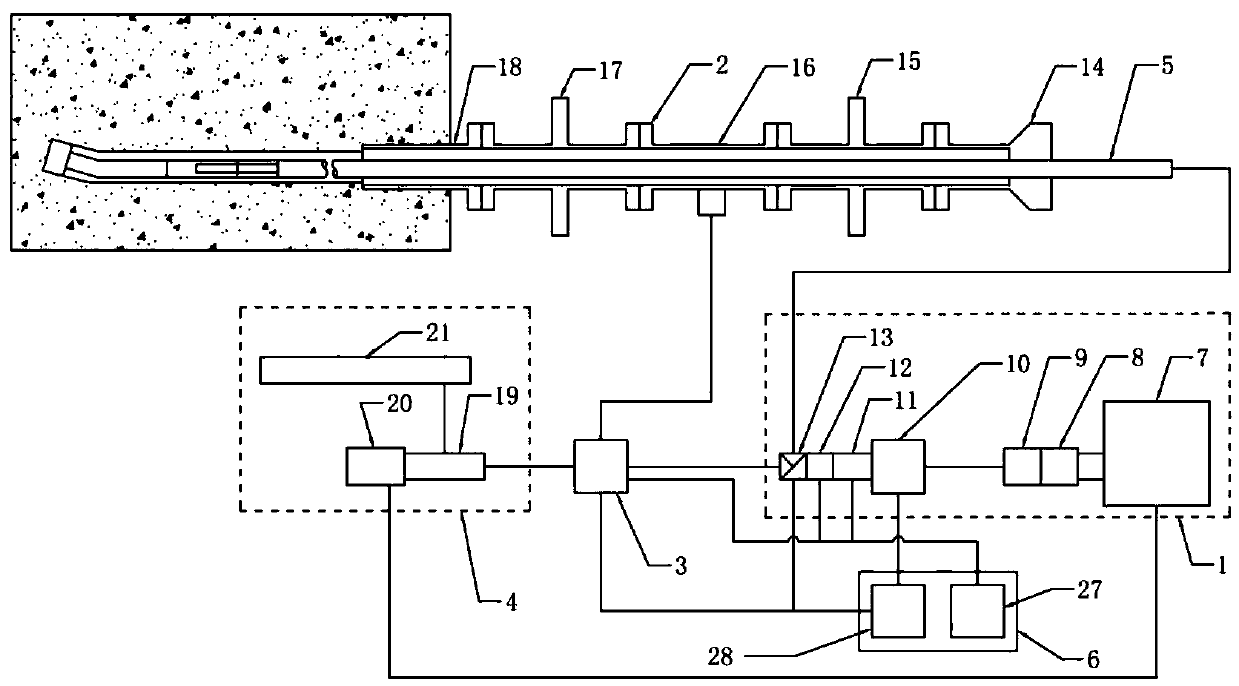

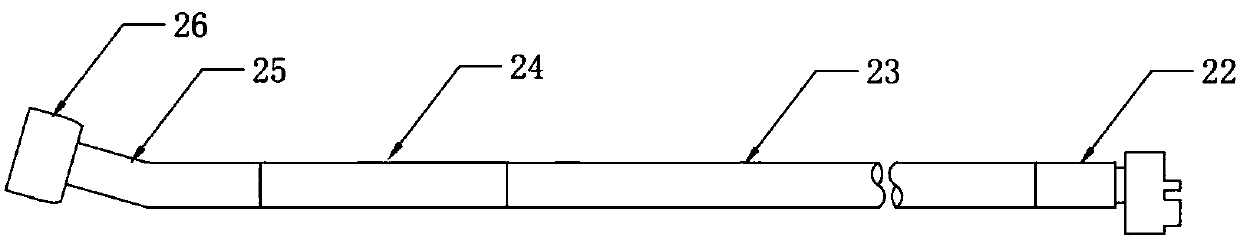

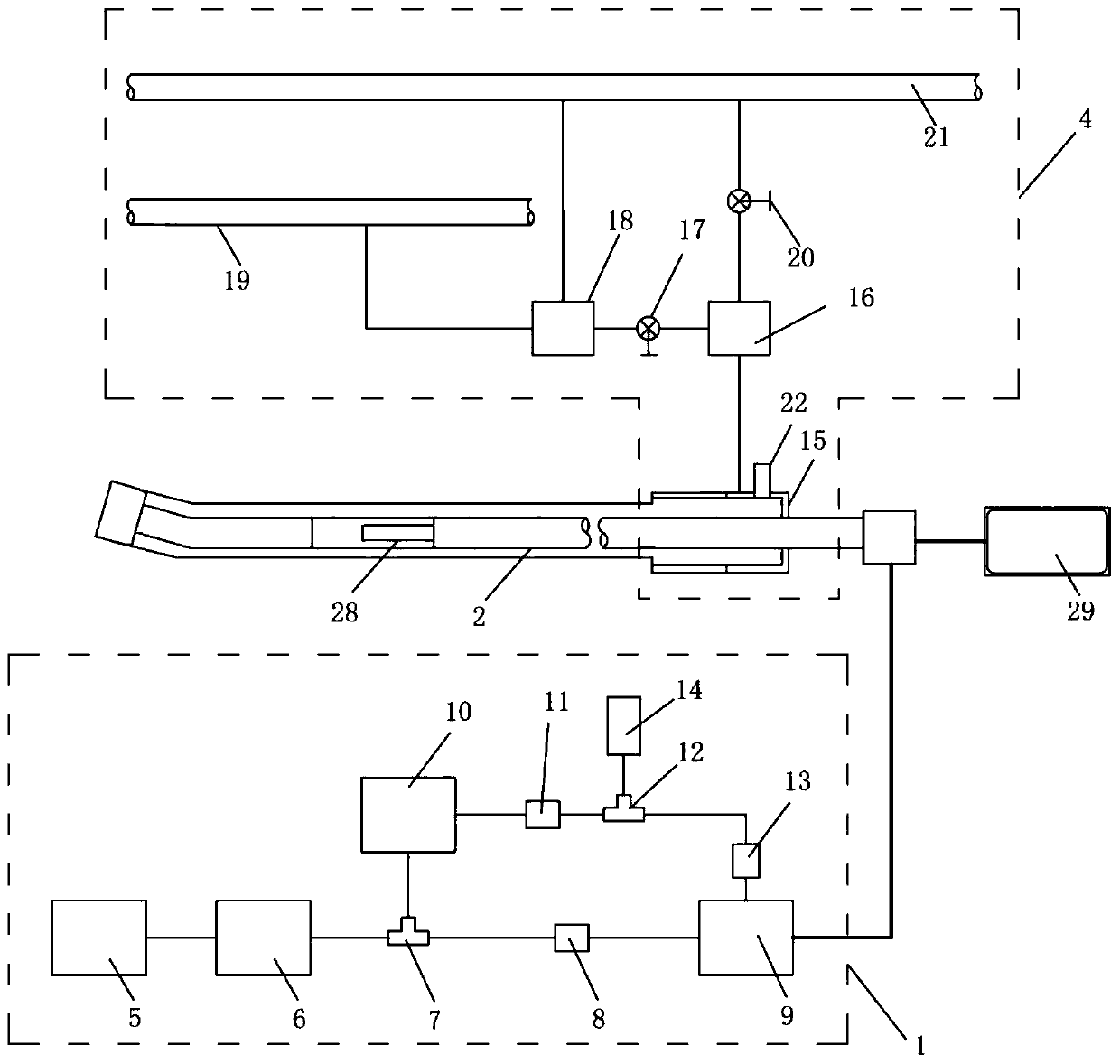

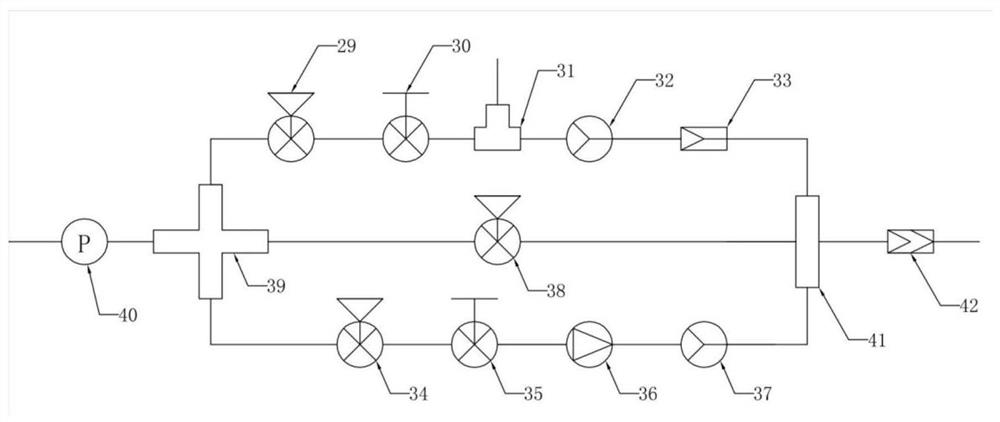

Adjustable gas directional drilling equipment and method for crushed soft coal seam in underground coal mine

ActiveCN110242215AImprove securityAvoid fire in holeConstructionsDirectional drillingSoft CoalsRock breaking

The invention relates to adjustable gas directional drilling equipment and method for a crushed soft coal seam in an underground coal mine. The equipment is composed of an orifice mixed gas supply system, a mine wired measurement while drilling device, a directional drilling tool assembly, an orifice waste gas treatment system and the like, two optional gas of pressurized air and nitrogen are supplied to a borehole by using the orifice mixed gas supply system, and the directional drilling tool assembly is driven for hole bottom high-efficiency rock breaking and drilling cutting discharging; borehole track while drilling real-time measurement and high-efficiency transmission are conducted by using the mine wired measurement while drilling device; measurement while drilling signal transmission and borehole track precise control are conducted by using the directional drilling tool assembly; and the orifice waste gas treatment system is used for removing boring mud and ensuring safe emission of the nitrogen and high-efficiency extraction of gas. The safety of drilling using the gas, the signal transmission efficiency and the slagging efficiency are overall improved, and potential safety hazards such as fire catching in the hole during gas drilling are avoided.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Redressing-while-drilling machine for drilling engineering and redressing method

InactiveCN108533180AApplicable to a wide range of formationsImprove impact resistanceDrill bitsConstructionsCarrying capacityWell drilling

The invention discloses a redressing-while-drilling machine for drilling engineering. The redressing-while-drilling machine for drilling engineering comprises a cylinder body and three spiral-shaped blade wings, the three blade wings are evenly fixed to the cylinder body. The blade wings comprise blade wing bodies, PDC clad sheet cutting teeth and gauge protection flat teeth. Every blade wing bodies is evenly provided with 13-17 PDC clad sheet cutting teeth, and the gauge protection portions of the blade wing bodies are evenly provided with the gauge protection flat teeth. The redressing-while-drilling machine for drilling engineering is simple in structure, redressing while drilling is performed by using the redressing-while-drilling machine, the well wall can be cleaned and scraped whiledrilling, so that the well wall can be corrected, the redressing effect is improved, hole shrinkage is eliminated and a mould bed is cleaned, and the size of a hole diameter is ensured. The redressing machine can change the flow field of drilling fluid in a well, rotational flow upwards going of the drilling fluid and rock debris is facilitated, and the sand-carrying capacity of the drilling fluid is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

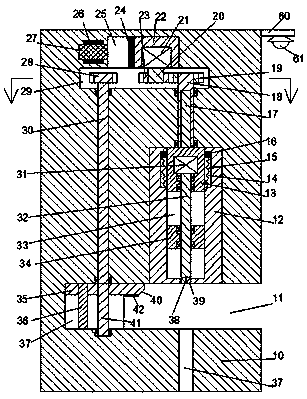

Drilling tool for detecting temperature in drill hole in real time

InactiveCN103590753AAvoid burnsImprove drilling safetySurveyDrilling rodsProcess informationPetroleum engineering

The invention relates to drilling tools, in particular to a drilling tool for detecting temperature in a drill hole in real time. The drilling tool for detecting the temperature in the drill hole in real time solves the technical problems that according to a drilling tool in the prior art, the temperature in the drill hole cannot be detected in real time and cannot be fed back to an operator in time. According to the technical scheme, the drilling tool for detecting the temperature in the drill hole in real time comprises a drill pipe, a fixing support, a temperature detecting emitting device and a signal receiving device; the temperature detecting emitting device is connected with the signal receiving device and the temperature detecting emitting device is fixed to the inner portion of the drill pipe through the fixing support; the temperature detecting emitting device is used for detecting the temperature in the drill hole and sending processed information to the signal receiving device; the signal receiving device is used for receiving the temperature information sent by the temperature detecting emitting device and making a corresponding response according to the temperature information. The drilling tool for detecting the temperature in the drill hole in real time is simple in structure, capable of detecting the temperature in the drill hole in real time and improving the safety and suitable for mine drilling.

Owner:SICHUAN UNIV

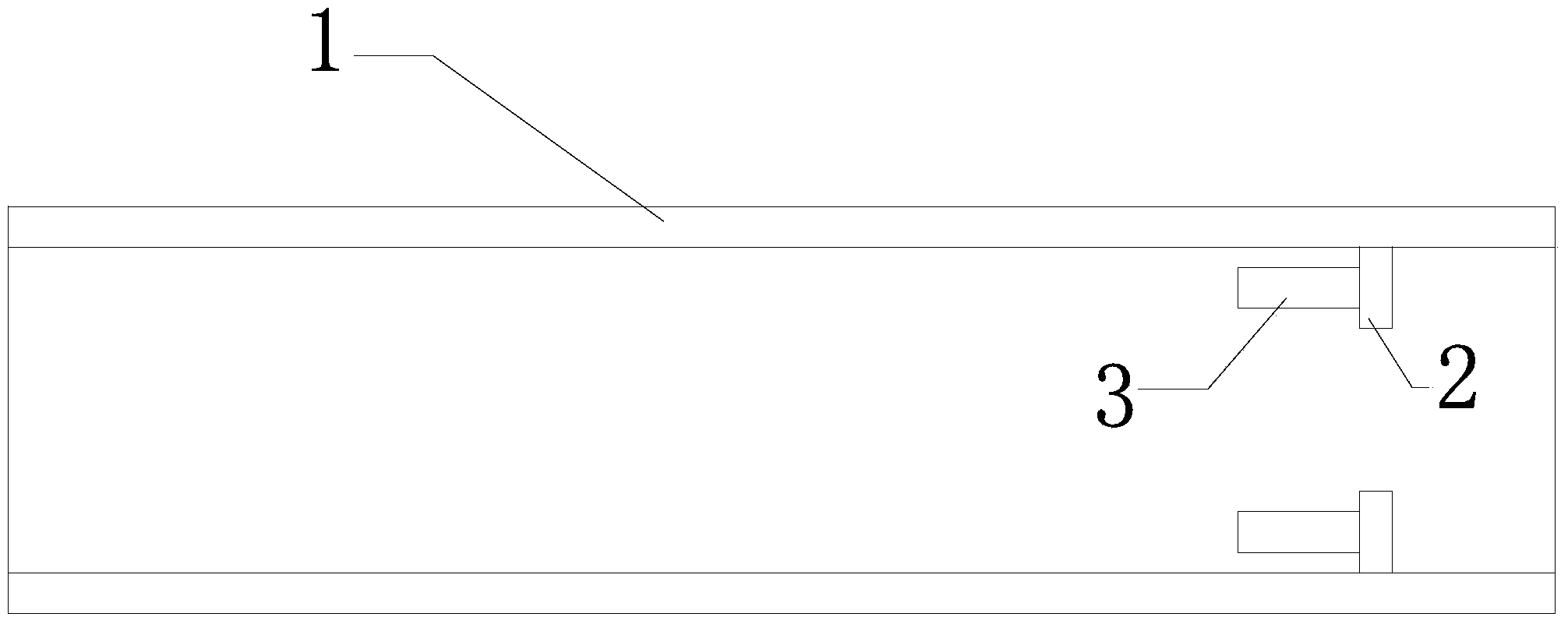

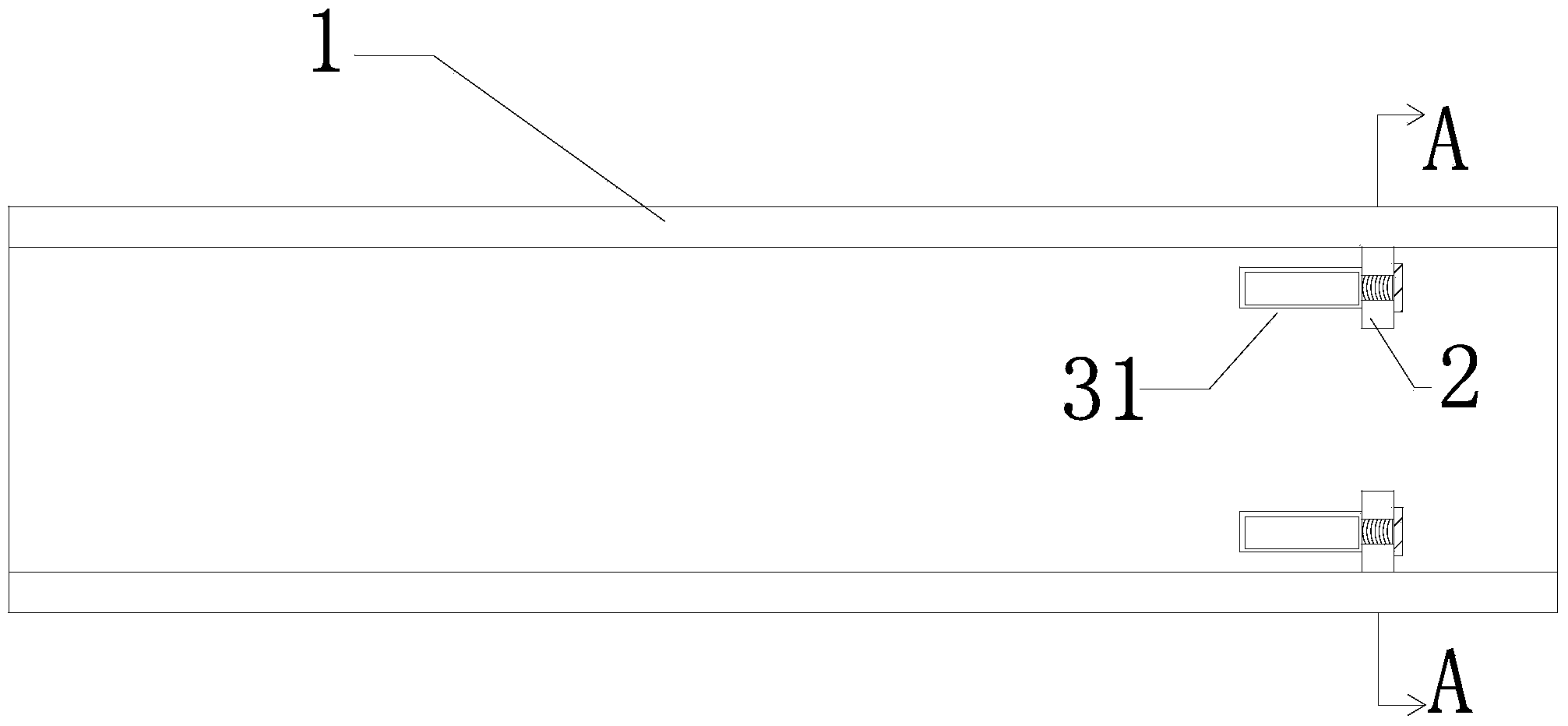

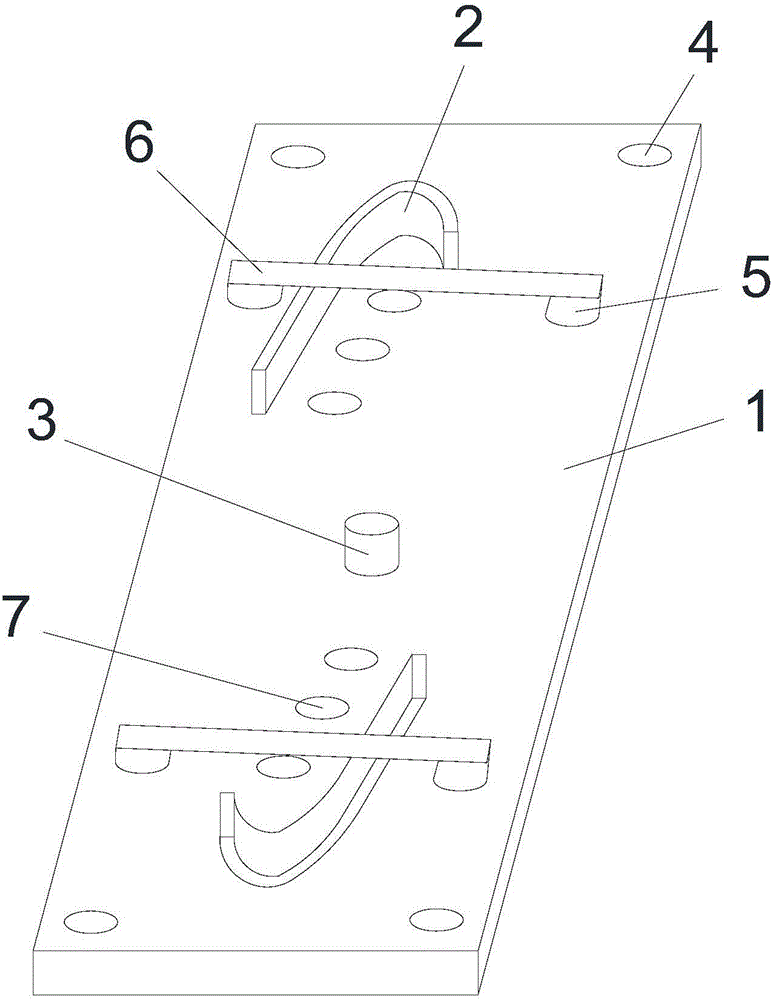

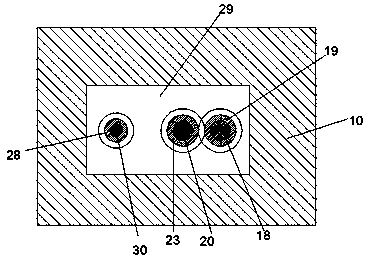

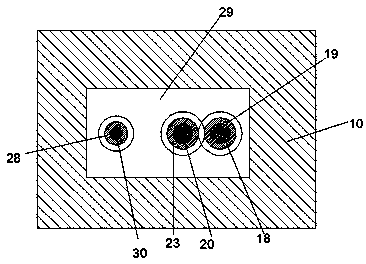

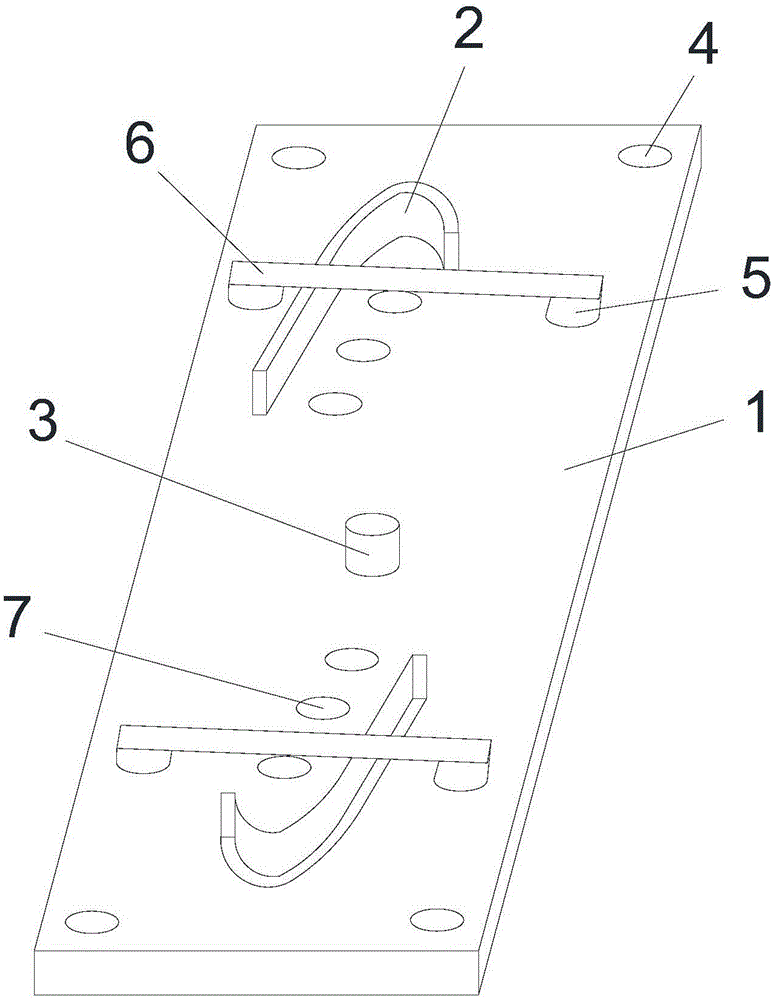

Drilling tool plate

ActiveCN105922031AImprove drilling safetyImprove drilling efficiencyPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention discloses a drilling tool plate. The drilling tool plate comprises a base and a pair of locating baffles, wherein the locating baffles are in central symmetry with the center point of the base as the symmetry point and are welded to the base; the center part of the base protrudes outwards for forming a hollow rotating shaft sleeve, and the rotating shaft sleeve can be arranged on a rotating shaft in a sleeving mode and rotates for driving the base to rotate with the center axis of the rotating shaft as the axis; two fixed piles are arranged at the parts, located on the two sides of each locating baffle, on the base, the height of the two fixed piles is smaller than the thickness of a work-piece to be drilled, and first through threaded holes are formed in the two fixed piles in the axial direction; a pressing strip is erected on the top ends of two fixed piles, second threaded holes are formed in the two ends of each pressing strip, and fixed bolts can sequentially penetrate through the second threaded holes and the first threaded holes for extruding the pressing strips on the outer wall of the work-piece to be drilled. The drilling tool plate is simple in structure, can fast locate the work-piece and pre-locate a next work-piece simultaneously, improves the drilling safety and improves the drilling work efficiency.

Owner:安徽百益科技有限公司

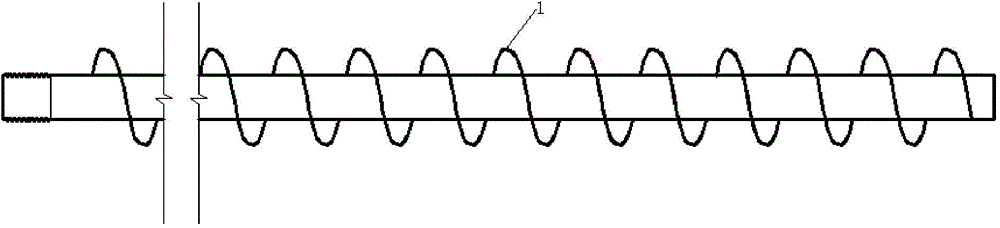

Device for determining Q, S and T values in combined mode

ActiveCN104612657AImprove drilling safetyEnsure safetySurveyMining devicesData acquisitionEngineering

The invention discloses a device for determining Q, S and T values in a combined mode, and belongs to the technical of mine safety. The device comprises a spiral drill pipe system, a drilling cutting collecting bag with holes, a gravity sensor, an air pump and a data collector. The spiral drill pipe system comprises a first spiral drill pipe and auxiliary spiral drill pipes connected with the first spiral drill pipe, a hollow cylinder is arranged in the middle of an inner cavity of the first spiral drill pipe, chucks are arranged on the inner wall of the middle of the cylinder and used for fixing the bottom end of a piston, a piston cavity is formed in the front end of the piston, formed by a wind resisting sleeve and the first spiral drill pipe in a surrounding mode and matched with the piston, and a temperature sensor is arranged at the position, adjacent to the outer wall and the cavity of the first spiral drill pipe, inside the wind resisting sleeve. An air feeding pipe is arranged on the inner wall of the first spiral drill pipe and communicated with the cylinder, a measuring pipe is further arranged inside the inner cavity of the first spiral drill pipe and penetrates through the cylinder and the piston, and a hole sealing device is arranged at the tail of the last auxiliary spiral drill pipe section. The drilling cutting collecting bag with the holes is arranged on the gravity sensor, the air pump is connected with the air feeding pipe, the data collector is connected with the tail of the measuring pipe, and the device is suitable for prediction in prevention of mine outburst.

Owner:SICHUAN UNIV +1

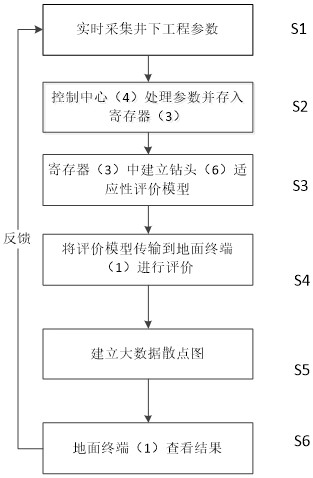

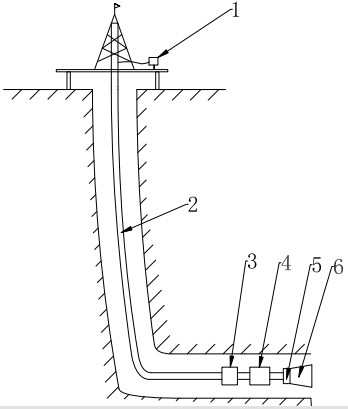

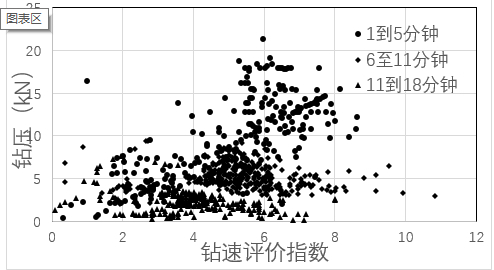

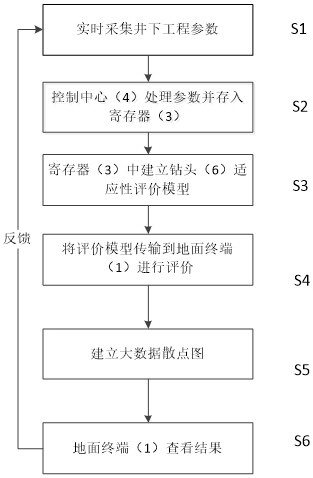

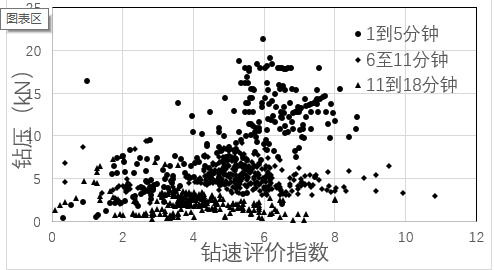

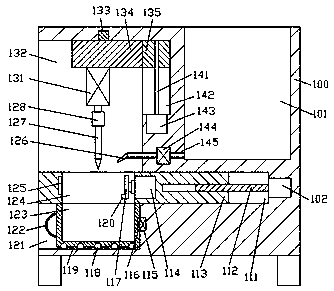

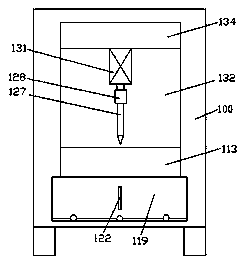

Evaluation data processing method and system based on underground engineering parameters

ActiveCN113034001AMonitoring bit pressureMonitor speedResourcesAutomatic control for drillingThermodynamicsWell drilling

The invention discloses an evaluation data processing method and system based on underground engineering parameters, and relates to the technical field of oil and gas exploitation. The method comprises the steps that characteristic parameters such as bit pressure, rotating speed, torque, displacement and drill bit vibration in different time periods are obtained in real time through a near-drilling sensor and sent to a control center to be processed, the processed parameters are stored in a register, and an evaluation model is established through an extreme value search algorithm for evaluation analysis; a historical data scatter diagram is established through the evaluation model and comprehensive drilling experience, and underground working conditions are judged and fed back to an underground drill bit. According to the method, parameters such as the bit pressure, the rotating speed, the torque, the displacement and drill bit vibration in the drilling process can be read in real time, the evaluation model is established to evaluate and analyze the underground working condition, the hysteretic nature of the above-well evaluation analysis amount is overcome, the drilling safety and the drilling efficiency are improved, and the drilling cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

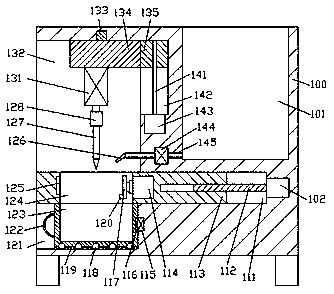

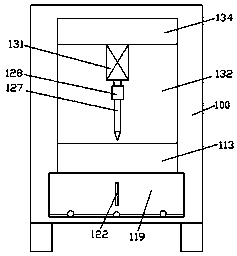

Novel metal plate drilling device

InactiveCN108526524ASimple structureEasy to usePositioning apparatusBoring/drilling componentsEngineeringDrill bit

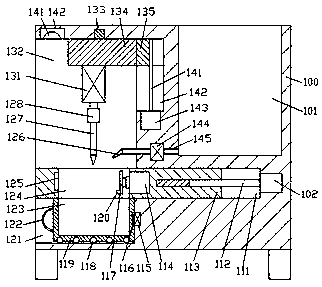

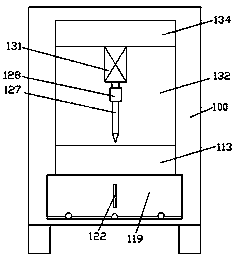

The invention discloses a novel metal plate drilling device. The drilling device comprises a machine body, a loading cavity with a rightward opening is formed in the machine body, a first sliding groove with a downward opening is formed in the top wall of the loading cavity, and a first sliding block capable of sliding up and down is installed in the first sliding groove; a second sliding groove with an upward opening is formed in the first sliding block, a through groove communicating with the outside is formed in the bottom wall of the second sliding groove, and a second sliding block and athird sliding block are arranged in the second sliding groove in a sliding mode, wherein the third sliding block is positioned below the second sliding block; and a drill rod extending downwards is arranged in the second sliding block in a rotatable mode, the lower end of the drill rod penetrates through the third sliding block and is in rotary fit with the third sliding block through a bearing, and a drill bit part which extends into the through groove is arranged at the lower end of the drill rod.

Owner:福建欧捷鑫金属科技有限公司

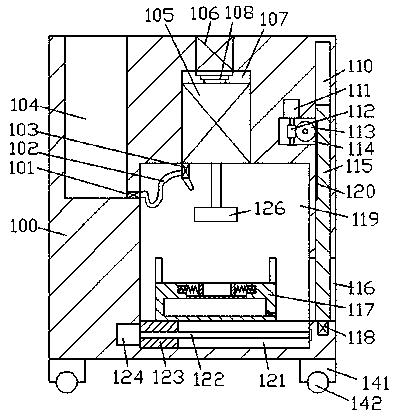

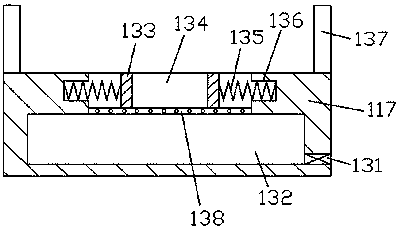

Novel electronic communication processing equipment

InactiveCN108465835ASimple structureEasy to operateFeeding apparatusMaintainance and safety accessoriesElectronic communicationEngineering

The invention discloses novel electronic communication processing equipment. The equipment comprises a processing main body; supporting legs are fixedly arranged on the periphery of the bottom end surface of the processing main body; rolling wheels are arranged on the bottom end surfaces of the supporting leg parts in a rotating fit mode; a containing cavity is formed in an inner wall body of theprocessing main body; a clamping base is arranged on the bottom end wall of the containing cavity in a sliding fit mode; a clamping cavity is formed in the top end surface of the clamping base; concave embedding cavities are symmetrically formed in the inner walls of the left side and the right side of the clamping cavity; elastic pressing parts are fixedly arranged in the concave embedding cavities; pushing plates which are fixedly connected to the elastic pressing parts on the left side and the right side are arranged in the clamping cavity in a sliding fit mode; a storage cavity is formed in the position, at the bottom end of the clamping cavity, of the clamping base; a screen is arranged between the storage cavity and the clamping cavity; an opening and closing valve penetrating through the right end surface of the clamping base is arranged at the bottom end of the right side of the storage cavity; a groove communicating with the containing cavity is formed in the end surface of the right side of the processing main body; and a first sliding cavity is formed in the inner bottom wall of the containing cavity.

Owner:张双锥

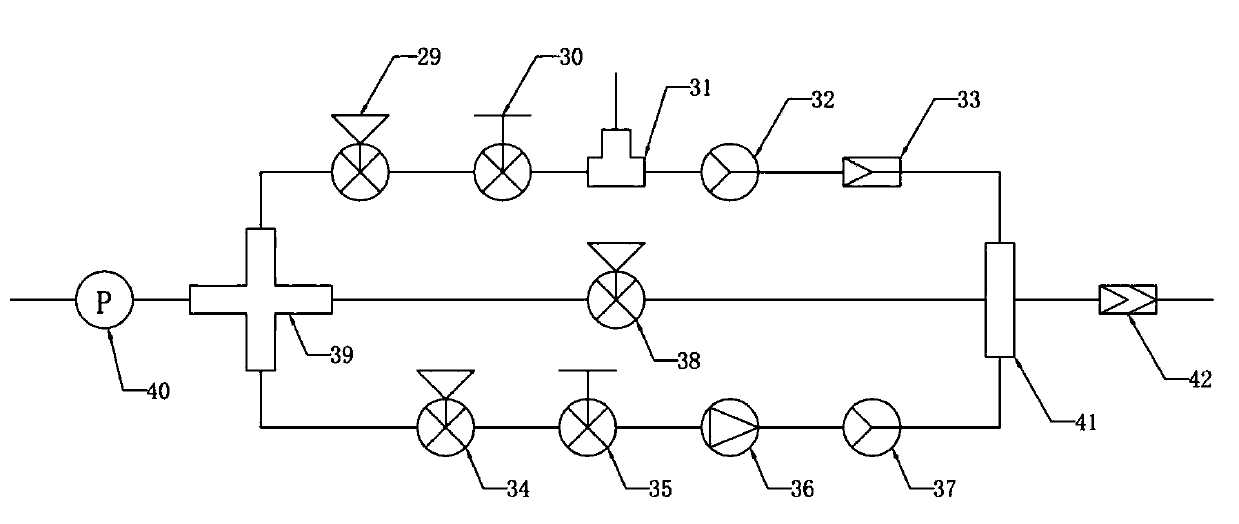

Wellhead safety operation method based on axial oblique-injection and suction drainage assistance

ActiveCN110500064AImprove drilling safetyConducive to the advantages of drilling speed increaseFluid removalSealing/packingLine tubingWell drilling

The invention provides a wellhead safety operation method based on axial oblique-injection and suction drainage assistance. The operation method adopts a wellhead safety operation system based on theaxial oblique-injection and suction drainage assistance to realize the suction effect on combustible gas at a wellhead; the system includes a sand discharge pipeline, an axial oblique-injection and suction drainage assistance mechanism connecting the wellhead and the sand discharge pipeline, an ignition device, a gas injection unit and a first gas injection manifold; the first gas injection manifold provides inert gas produced by the gas injection unit to the inclined injection suction and drainage mechanism to form the negative pressure suction effect; and the ignition device is arranged at the outlet end of the sand discharge pipeline and ignites combustible gas discharged from the sand discharge pipeline. According to the operation method, a nitrogen injection suction method with doublechannel suction and adjustable gas injection can be realized, the safety risk of natural gas overflowing from the wellhead when "tripping operation and rubber core replacing" and other open well operation are carried out under the condition that a small amount of natural gas is produced from a formation is reduced, the safety of field operation is significantly improved, the operation method facilitates the development of gas drilling speed-up advantages, and is applicable to the field of reverse circulation drilling.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

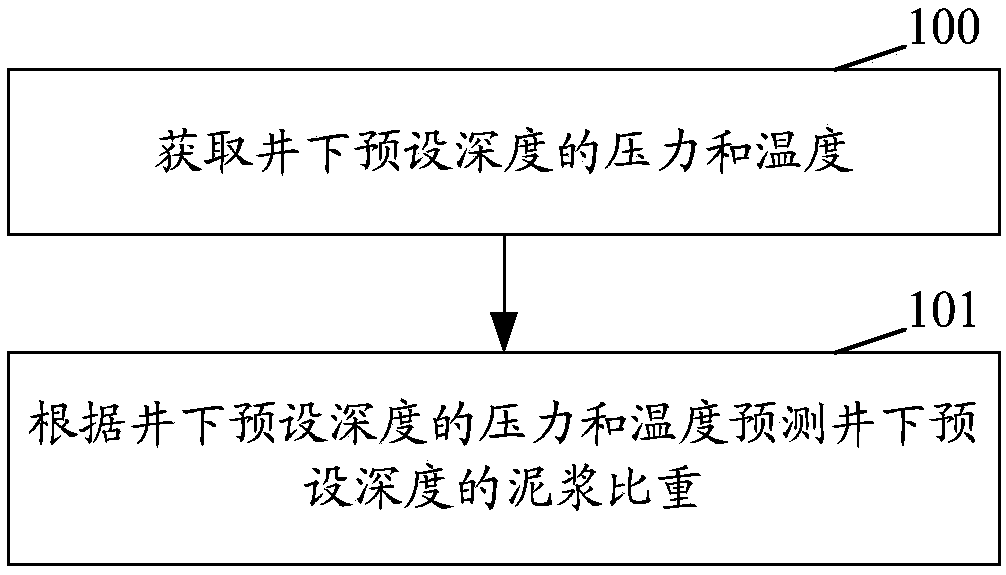

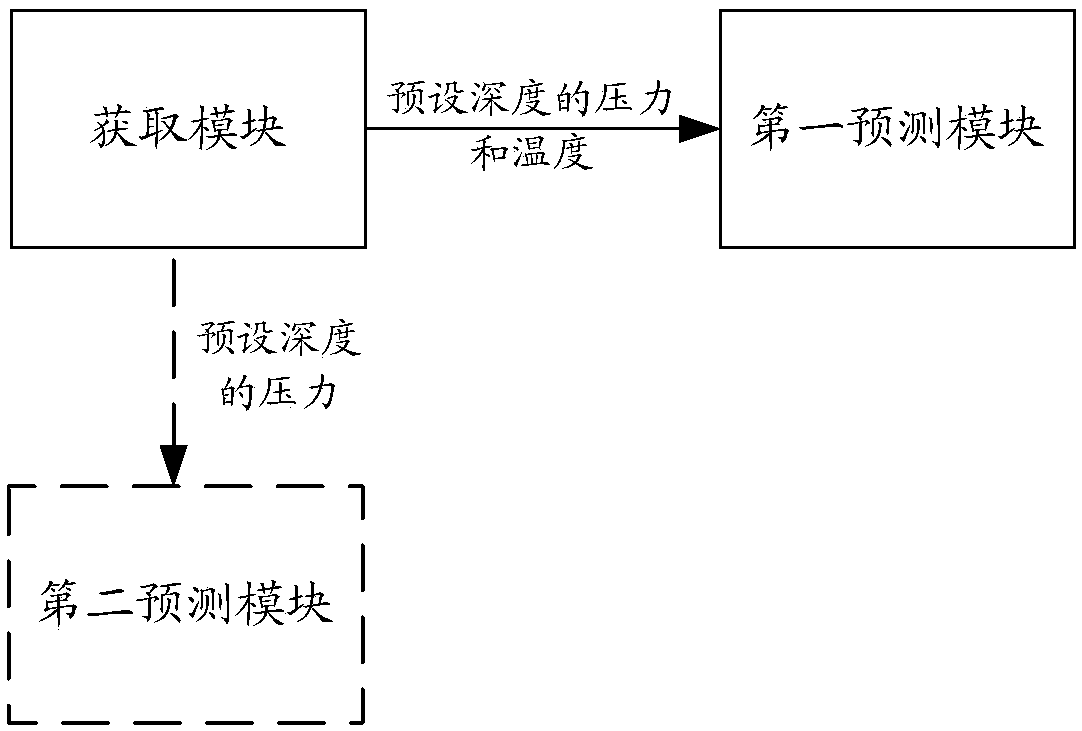

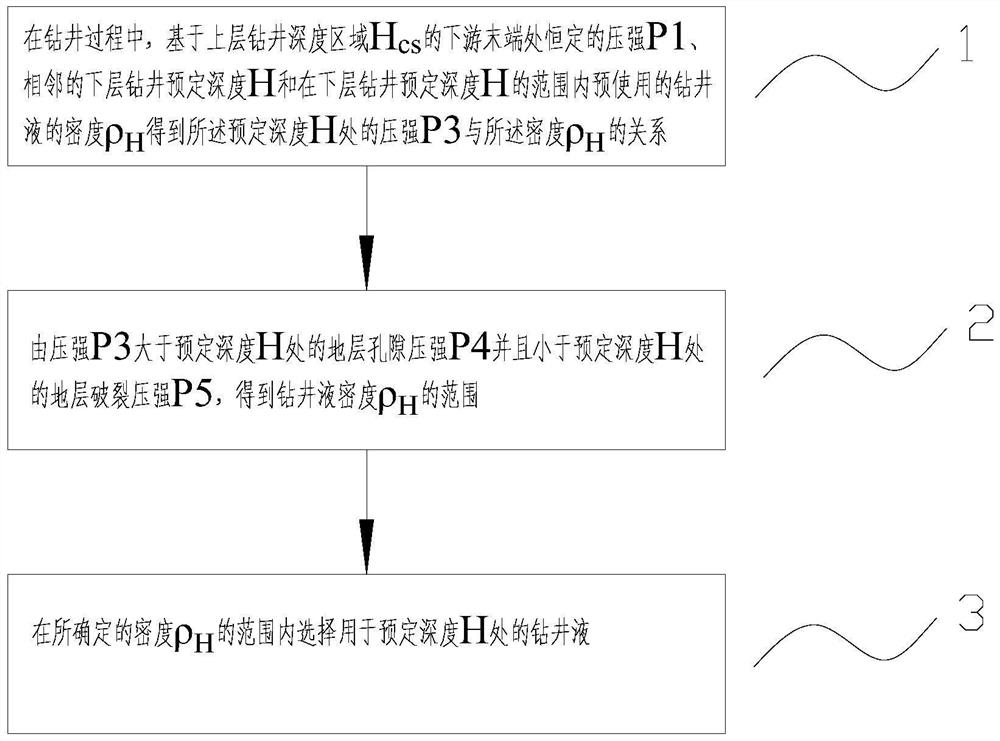

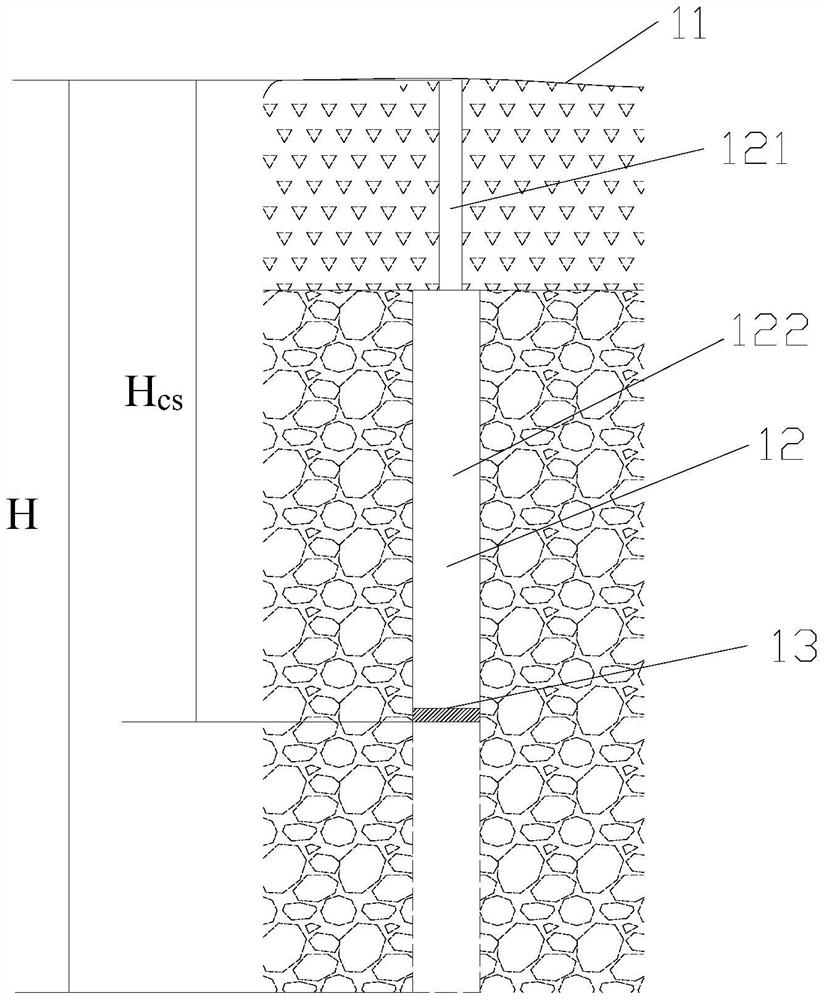

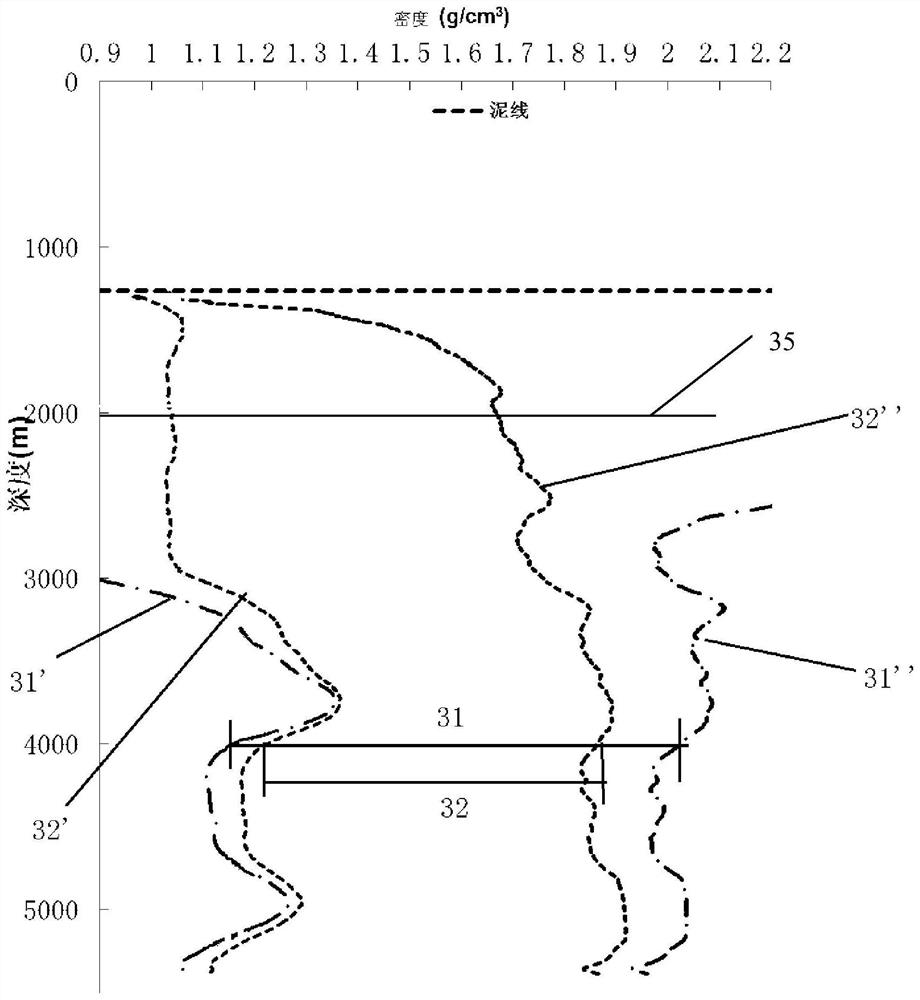

Prediction method and prediction device for specific gravity of underground mud

ActiveCN108460477AImprove drilling safetyReduce or even eliminate well control accidentsForecastingWell drillingPredictive methods

The invention discloses a prediction method and a prediction device for specific gravity of underground mud. The prediction method comprises the following steps that the pressure and the temperature of the underground preset depth are obtained; the mud specific gravity of the underground preset depth is predicted according to the pressure and the temperature of the underground preset depth. According to the method, the mud specific gravity of the underground preset depth is accurately predicted based on the pressure and temperature of the underground preset depth, so that the drilling safety is improved, and the well control accident is reduced or even eliminated.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Metal plate drilling device

InactiveCN108500325ASimple structureEasy to useFeeding apparatusDriving apparatusDrill pipeGeotechnical engineering

The invention discloses a metal plate drilling device comprising a device body. A loading cavity with a rightward opening is formed in the device body, a first sliding groove with a downward opening is formed in the top wall of the loading cavity, and a first sliding block which can slide up and down is mounted in the first sliding groove; a second sliding groove with an upward opening is formed in the first sliding block, a through groove communicating with the exterior is formed in the bottom wall of the second sliding groove, and a second sliding block and a third sliding block located below the second sliding block are slidably mounted in the second sliding groove; and a drilling rod extending downwards is rotatably mounted in the second sliding block, the lower end of the drilling rodpenetrates through the third sliding block and is rotatably matched with the third sliding block through a bearing, and the lower end of the drilling rod is provided with a drilling bit part stretching into the through groove.

Owner:福建欧捷鑫金属科技有限公司

Improved sheet metal drilling device

InactiveCN108480682ASimple structureEasy to useBoring/drilling machinesEngineeringMechanical engineering

The invention discloses an improved sheet metal drilling device. The improved sheet metal drilling device comprises a machine body. The machine body is internally provided with a loading cavity with arightward opening. The top wall of the loading cavity is internally provided with a first sliding groove with a downward opening. The first sliding groove is internally provided with a first slidingblock which can slide up and down. The first sliding block is internally provided with a second sliding groove with an upward opening. The bottom wall of the second sliding groove is internally provided with a through groove communicating with the exterior. The second sliding groove is internally provided with a second sliding block and a third sliding block located below the second sliding blockin a sliding manner. The second sliding block is internally and rotationally provided with a downwards extending drilling rod. The lower end of the drilling rod penetrates the third sliding block andthe third sliding block and is in rotating fit through a bearing, and the lower end of the drilling rod is provided with a drill bit part extending into the through groove.

Owner:福建欧捷鑫金属科技有限公司

Electronic communication processing equipment

InactiveCN108422006ASimple structureEasy to operateFeeding apparatusLarge fixed membersElectronic communicationEngineering

The invention discloses electronic communication processing equipment. The electronic communication processing equipment comprises a processing main body, wherein supporting legs are fixedly arrangedon the periphery of the end surface of the bottom of the processing main body; a roller is mounted in the bottom end surface of each supporting leg in a running fit manner; a cavity is formed in the inner wall body of the processing main body; an impaction seat is mounted on the bottom end wall of the cavity in a sliding fit manner; an impaction cavity is formed in the top end surface of the impaction seat; recessed cavities are symmetrically formed in the inner walls of the left side and the right side of the impaction cavity; a spring piece is fixedly arranged in each recessed cavity; a pushing plate which is fixedly connected with the spring pieces on the left side and the right side is mounted in the impaction cavity in a sliding fit manner; a storage cavity is formed in the impactionseat and positioned at the bottom end of the impaction cavity; a screen is arranged between the storage cavity and the impaction cavity; an opening and closing valve which penetrates through the rightend surface of the impaction seat is arranged at the bottom end of the right side of the storage cavity; a slot which communicates with the cavity is formed in the right end surface of the processingmain body; and a first sliding cavity is formed in the inner bottom wall of the cavity.

Owner:张双锥

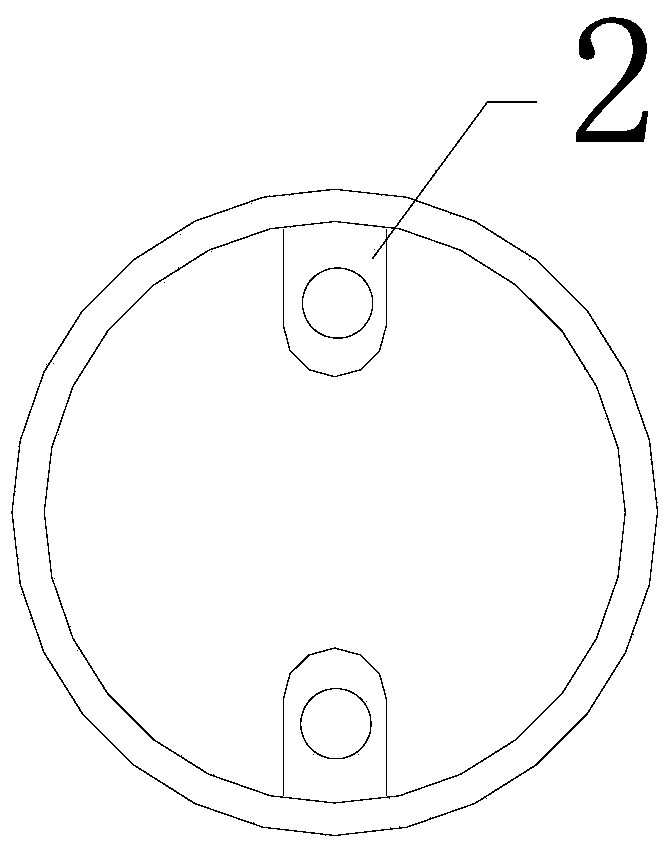

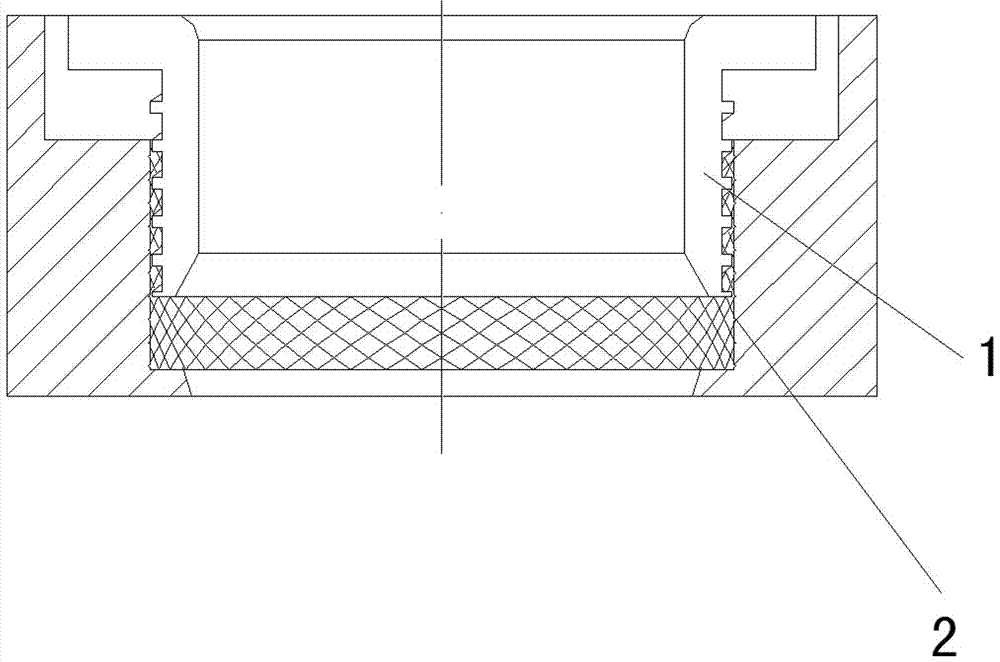

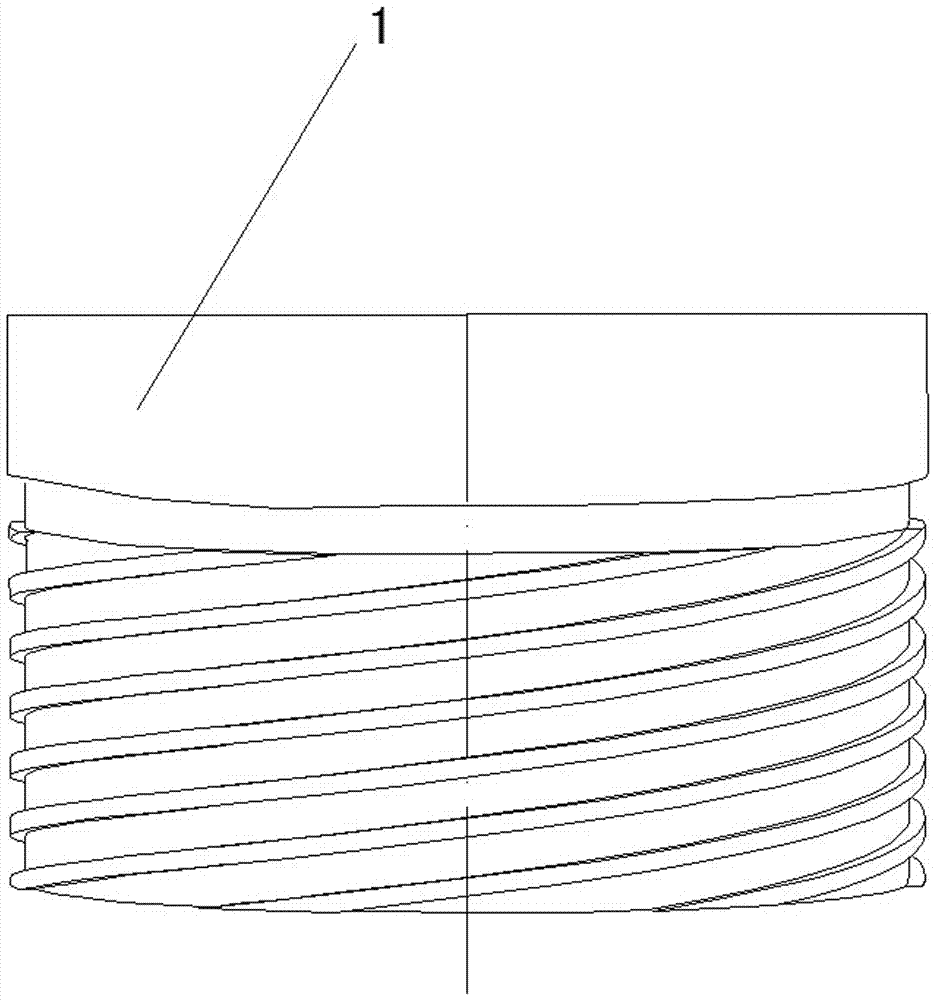

Spiral grid type anti-clamping sealing structure

ActiveCN107515134AAvoid economic lossImprove sealing propertiesWithdrawing sample devicesKnurlingCoring

The invention discloses a spiral grid type anti-clamping sealing structure, belongs to the field of sampling detection, provides a sealing function interface without a sealing part and aims to a rotary moving pair working condition of incomplete sealing. A coring bit end is of a hollow structure; a sample outer protection tube shaft end is arranged inside the coring bit end; the coring bit end is in sliding matching with a gap of the sample outer protection tube shaft end; threads are formed in the outer surface of the sample outer protection tube shaft end; groove-shaped grids are formed in the inner surface of the coring bit end; or knurling is formed in the inner surface of the coring bit end. Compared with a conventional sealing mode, the structure needs no sealing part and has the advantages of good sealing properties, good environmental adaptation, non-sensitive sealing gaps and the like. By adopting the structure, not only is the drilling security greatly improved, but also a great deal of economic loss caused by engineering failure is avoided.

Owner:HARBIN INST OF TECH

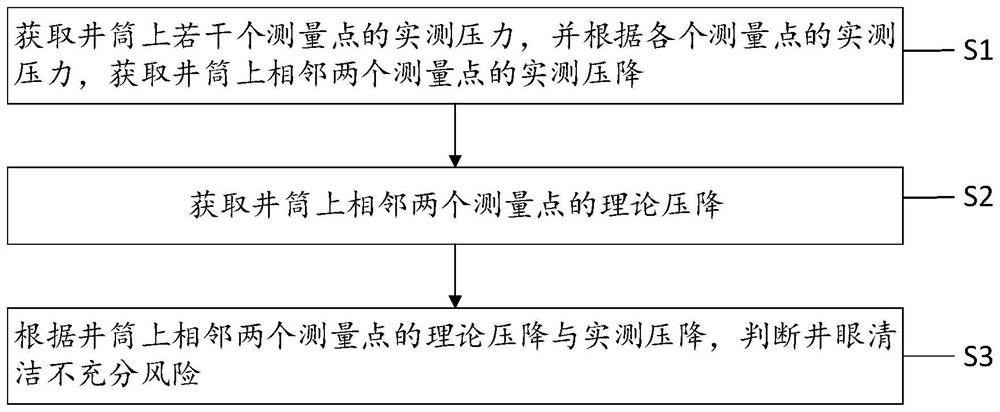

Method, device and system for evaluating risk of insufficient borehole cleaning

PendingCN114198087AImprove drilling safetyPressure drop changeSurveyConstructionsFriction effectGeotechnical engineering

The invention discloses a method, device and system for evaluating the risk of insufficient borehole cleaning, and the method comprises the steps: obtaining the actual measurement pressure of a plurality of measurement points on a wellbore, and obtaining the actual measurement pressure drop of two adjacent measurement points on the wellbore according to the actual measurement pressure of each measurement point; obtaining the theoretical pressure drop of two adjacent measuring points on the shaft; and according to the theoretical pressure drop and the actually measured pressure drop of the two adjacent measuring points on the wellbore, the risk of insufficient borehole cleaning is judged. The method has the advantages that the theoretical pressure drop between every two adjacent measuring points on the shaft comprises the pressure drop caused by the friction effect and the pressure drop caused by hydrostatic pressure, but the pressure drop in a well hole can be obviously changed by suspended rock debris in actual drilling fluid. And if a large amount of rock debris exists, the calculated theoretical pressure drop and the actually measured pressure drop have obvious difference, so that the relationship between the theoretical pressure drop and the actually measured pressure drop can be compared to evaluate the underground borehole cleaning condition and judge the risk of insufficient borehole cleaning.

Owner:YANGTZE UNIVERSITY

Drilling tooling plate

ActiveCN105922031BImprove drilling safetyImprove drilling efficiencyPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention discloses a drilling tool plate. The drilling tool plate comprises a base and a pair of locating baffles, wherein the locating baffles are in central symmetry with the center point of the base as the symmetry point and are welded to the base; the center part of the base protrudes outwards for forming a hollow rotating shaft sleeve, and the rotating shaft sleeve can be arranged on a rotating shaft in a sleeving mode and rotates for driving the base to rotate with the center axis of the rotating shaft as the axis; two fixed piles are arranged at the parts, located on the two sides of each locating baffle, on the base, the height of the two fixed piles is smaller than the thickness of a work-piece to be drilled, and first through threaded holes are formed in the two fixed piles in the axial direction; a pressing strip is erected on the top ends of two fixed piles, second threaded holes are formed in the two ends of each pressing strip, and fixed bolts can sequentially penetrate through the second threaded holes and the first threaded holes for extruding the pressing strips on the outer wall of the work-piece to be drilled. The drilling tool plate is simple in structure, can fast locate the work-piece and pre-locate a next work-piece simultaneously, improves the drilling safety and improves the drilling work efficiency.

Owner:安徽百益科技有限公司

Drilling Fluid Selection Method for Subsea Drilling and Its Use in Drilling Depth Calculation

Owner:CHINA PETROLEUM & CHEM CORP +1

Machining robot with high safety

InactiveCN108422565ASimple structureEasy to operateWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention discloses a machining robot with high safety. The machining robot comprises a machining machine body, a machining cavity is formed in the left side end surface of the machining machine body, the bottom wall of the machining cavity communicates with a first sliding cavity which extends rightwards, the bottom wall of the first sliding cavity communicates with a second sliding cavity, the first sliding cavity and the second sliding cavity penetrate through the left side end surface of the machining machine body correspondingly, a mounting block is arranged in the machining cavity ina sliding fit mode, a drilling machine body is fixedly arranged at the bottom end of the mounting block, a drill bit connector is arranged at the bottom end of the drilling machine body, a drilling head is detachably installed in the bottom end of the drill bit connector, a lifting driving mechanism is arranged on the right side end surface of the mounting block in a power fit mode, a sliding seat is arranged in the first sliding cavity in a sliding fit mode, a clamping cavity is arranged in the left side extending section of the sliding seat in an up-down penetrating mode, the clamping cavity communicates with the machining cavity, and an air pressure cylinder is fixedly arranged in the inner wall of the right side of the clamping cavity.

Owner:詹贺钫

A method and system for processing evaluation data based on downhole engineering parameters

ActiveCN113034001BMonitoring bit pressureMonitor speedResourcesAutomatic control for drillingThermodynamicsWell drilling

The invention discloses a data processing method and system based on downhole engineering parameter evaluation, and relates to the technical field of oil and gas exploitation; comprising the steps of: using a near-drilling sensor to obtain real-time drilling pressure, rotational speed, torque, displacement, and drill bit vibration in different time periods characteristic parameters, and send them to the control center to process the parameters, store the processed parameters in the register and use the extreme value search algorithm to establish an evaluation model for evaluation and analysis, establish a historical data scatter diagram through the evaluation model and comprehensive drilling experience, and judge the underground work. and feed back to the downhole drill bit. The invention can establish an evaluation model to evaluate and analyze the downhole working conditions by reading parameters such as drilling pressure, rotational speed, torque, displacement and bit vibration in the drilling process in real time, overcomes the hysteresis of uphole evaluation and analysis, and improves drilling efficiency. The safety and drilling efficiency are improved, and the drilling cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Processing robot

InactiveCN108437228ASimple structureEasy to operateWorking accessoriesManipulatorEngineeringMechanical engineering

The invention discloses a processing robot. The processing robot comprises a processing machine body, wherein a processing chamber is formed in the left side end surface of the processing machine body; a first sliding chamber which rightwards extends is formed in the bottom wall of the processing chamber in a communication manner; a second sliding chamber is formed in the bottom wall of the firstsliding chamber in a communication manner; the first sliding chamber and the second sliding chamber correspondingly pass through the left side end surface of the processing machine body; a mounting block is mounted in the processing chamber in a sliding fitting manner; a hole drilling machine body is fixedly arranged at the bottom end of the mounting block, and a drill bit connector is arranged atthe bottom end of the hole drilling machine body; a hole drill bit is detachably mounted in the bottom end of the drill bit connector; a lifting driving mechanism is mounted at the right side end surface of the mounting block in a power fitting manner; a sliding seat is mounted in the first sliding chamber in a sliding fitting manner; a clamping fixing chamber which penetrates the top and bottomis formed in the left side extending section of the sliding seat, and the clamping fixing chamber communicates with the processing chamber; and a pneumatic cylinder is fixedly arranged in the inner wall of the right side of the clamping fixing chamber.

Owner:詹贺钫

Stone processing robot

InactiveCN108422564ASimple structureEasy to operateWorking accessoriesStone-like material working toolsPneumatic cylinderEngineering

The invention discloses a stone processing robot. The stone processing robot comprises a processing machine body. A processing cavity is formed in the left end face of the processing machine body. A first sliding cavity extending to the right is communicated with the bottom wall of the processing cavity. A second sliding cavity is communicated with the bottom wall of the first sliding cavity. Thefirst sliding cavity and the second sliding cavity penetrate through the left end face of the processing machine body. A mounting block is mounted in the processing cavity in a sliding fit manner. A drilling machine body is fixedly arranged at the bottom end of the mounting block. A drilling head connecting device is arranged at the bottom end of the drilling machine boy. A drilling head is detachably mounted in the bottom end of the drilling head connecting device. A lifting drive mechanism is mounted on the right end face of the mounting block in a power fit manner. A sliding seat is mountedin the first sliding cavity in a sliding fit manner. A clamping and fixing cavity is formed in the left extending section of the sliding seat in a vertically penetrating manner. The clamping and fixing cavity is communicated with the processing cavity. A pneumatic cylinder is fixedly arranged in the inner wall of the right side of the clamping and fixing cavity.

Owner:詹贺钫

Composite Drilling Method for Drag and Torsion Reduction in Complex Structure Wells

ActiveCN103510871BReduce frictional torqueReduce drilling riskDrilling rodsDirectional drillingWell drillingDrop method

The invention discloses a complex structural well drag-reduction wrenching-reduction compound drilling method. An underground drag-reduction wrenching-reduction device is arranged between an upper-portion drilling rig and a measurement-while-drilling drilling assembly combination, and therefore the upper-portion drilling rig can rotate independently relative to the measurement-while-drilling drilling rig; a reaction torque balancing device is arranged between a power drilling rig and a drill bit, and the disturbance of the reaction torque generated by a power drilling rig to a tool face is eliminated. The complex structural well drag-reduction wrenching-reduction compound drilling method has the advantages that the drag-reduction wrenching-reduction device can change the drill string sliding drilling into rotary drilling during the guiding drilling process, the friction resistance and the torque loss are reduced, and the occurrence rate of complex situations that the drill string is stuck and clamped is reduced; the reaction torque balancing device can effectively eliminate the influence of the reaction torque generated by a power drilling rig on the tool face, the tool face is controlled to be stable, the well track control accuracy is improved, the well body quality is improved, and complex structure well efficient drilling is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Near-horizontal pressurized directional drilling equipment and method for complex fractured formations in underground coal mines

ActiveCN111502545BImprove hole wall stabilitySolve the key technical problems of pressurized drillingDrill bitsConstructionsMining engineeringUnderground tunnel

The invention relates to an underground coal mine tunnel drilling method, in particular to a near-horizontal pressurized directional drilling equipment and method for complex and broken formations underground in a coal mine. It includes: an orifice casing, which is used to close the orifice during construction; a directional drilling tool assembly, which passes through the orifice casing to enter the coal seam during construction, and is provided with a unidirectional drill tool center hole; throttling a pressurization system, connected to the first fluid channel formed between the directional drilling tool assembly and the orifice casing, and capable of recovering and inputting fluid from the first fluid channel; the present invention provides High-pressure flushing fluid, and the pressure of the flushing fluid is controlled, so that the radial additional support force of the flushing fluid on the hole wall is greater than the equilibrium pressure value of the hole wall, ensuring the stability of the drilling hole and avoiding the instability and damage of the drilling hole in complex and broken strata, and safety accidents High-incidence problems improve the hole formation rate and construction safety of various near-level geological exploration and disaster prevention drilling in underground coal mines.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

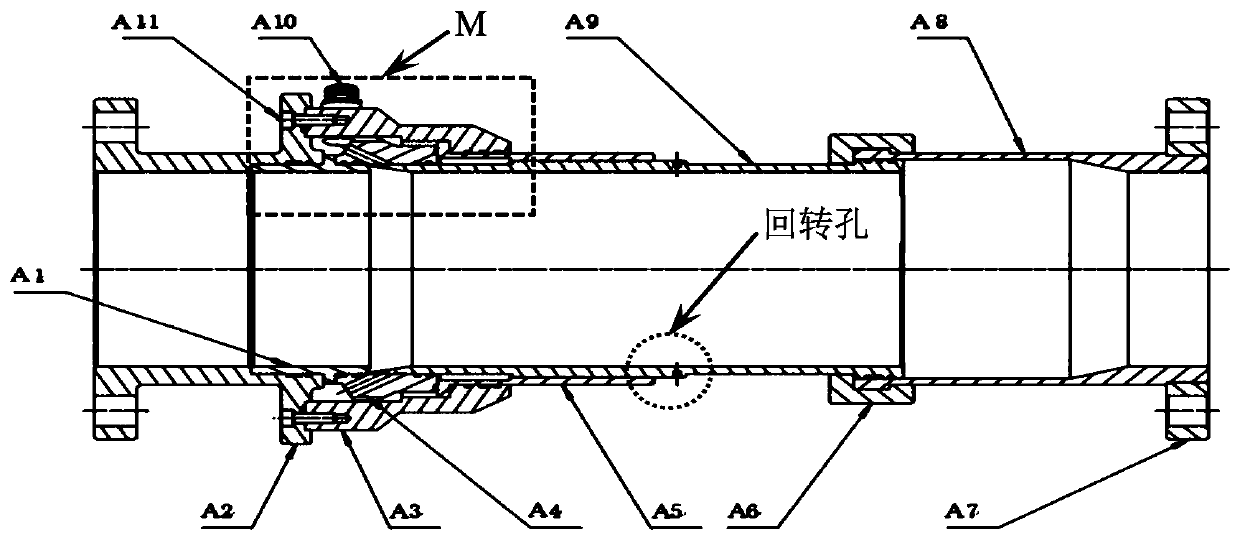

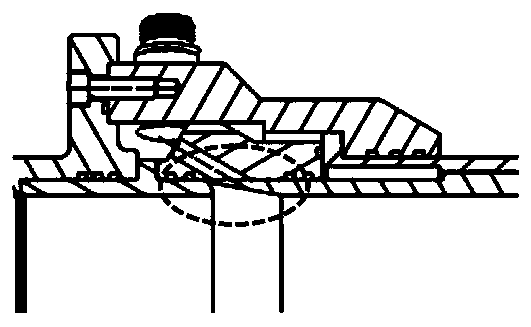

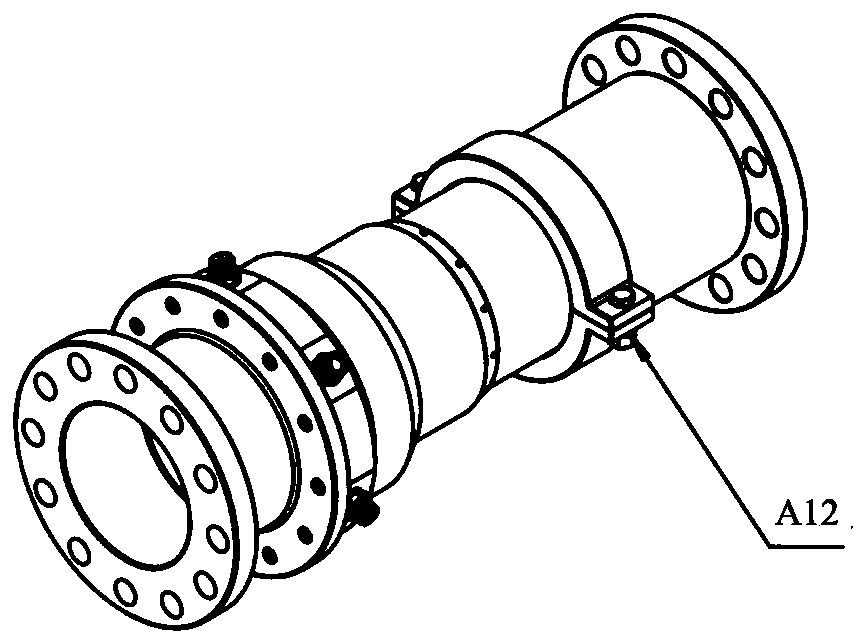

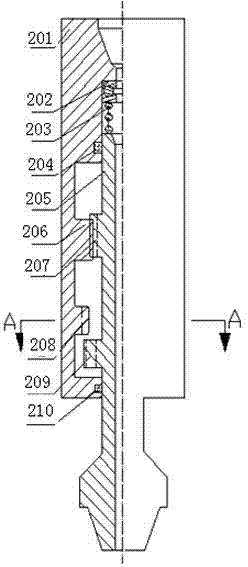

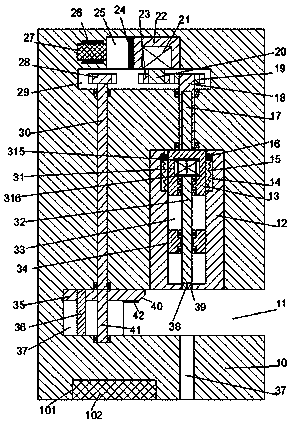

While-drilling jam release device for intelligent drilling

PendingCN111155953AEasy to handleEconomical and safe handlingBorehole/well accessoriesSolenoid valveUpper joint

The invention relates to a while-drilling jam release device for intelligent drilling. According to the while-drilling jam release device, through intelligent control over high-pressure drilling fluidand jet scrubbing of a bit mud drum from an annulus, while-drilling jam release is achieved. According to the technical scheme of the while-drilling jam release device for intelligent drilling, a driving assembly is arranged at the junction of an upper joint and a lower joint; the driving assembly is constituted by a driving assembly solenoid valve, a plunger, a spring, a center pipe and a checkblock; a liquid spraying assembly, a locking assembly and a main intercepting assembly are arranged on the upper joint; the liquid spraying assembly is constituted by a spring seat, a liquid sprayingvalve spring, a liquid spraying valve element, a liquid spraying valve seat, a liquid spraying valve deck and a flow pass; the locking assembly is constituted by a locking block and a locking valve seat; and the main intercepting assembly is constituted by a valve plate, a telescopic pin shaft, a torsional spring and a torsional spring close cover. The while-drilling jam release device has a while-drilling jam release function down hole and can be intelligently controlled, the non-working time of drilling is shortened, the drilling cost is reduced, and drilling safety is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Novel semiconductor material production technological equipment

InactiveCN108501101ASimple structureEasy to useMetal working apparatusSemiconductor materialsEngineering

The invention discloses novel semiconductor material production technological equipment. The equipment comprises a frame base. The frame base is provided with a containing cavity with a rightward opening. The top wall of the containing cavity is provided with a first sliding groove with a downward opening. A first sliding block capable of sliding up and down is mounted in the first sliding groove.The first sliding groove is provided with a second sliding groove with an upward opening. The bottom wall of the second sliding groove is provided with a through cavity communicating with the outside. A second sliding block and a third sliding block located below the second sliding block are slidably mounted in the second sliding groove. The second sliding block is rotatably provided with a drillrod extending downwards. The lower end of the drill rod penetrates through the third sliding block and is rotatably matched with the third sliding block through a bearing. The lower end of the drillrod is provided with a drill bit extending into the through cavity.

Owner:黄宝超

A kind of survey hole sampling device and control method

ActiveCN113340655BImprove drilling safetyAvoid engineering accidents such as hole collapse and slurry leakageWithdrawing sample devicesKarstSlurry

The invention relates to a reconnaissance hole sampling device and a control method. The device includes a drill cutting assembly, a high-pressure gas lift assembly, a high-pressure slurry delivery assembly, a sedimentation separation assembly, and a connection conversion assembly; wherein, the drill cutting assembly is connected to the connection conversion assembly; The lifting component is connected to the cutting and drilling component; one end of the high-pressure slurry feeding component is connected to the cutting and drilling component, and the other end is connected to the sedimentation and separation component; the sedimentation and separation component is used to process the received three-phase mixture to obtain sampling soil samples. The invention can realize the continuous extraction of soil samples when excavating the exploration holes, complete the exploration of ultra-deep series karst caves without pulling out casings, avoid the occurrence of engineering accidents such as hole collapse and slurry leakage, and improve the safety of drilling in karst cave areas Under the premise, the effect of improving the construction efficiency can be achieved, and at the same time, there is no need to manually extract and knock the drill pipe, and the degree of construction automation can be improved.

Owner:中电建路桥集团有限公司

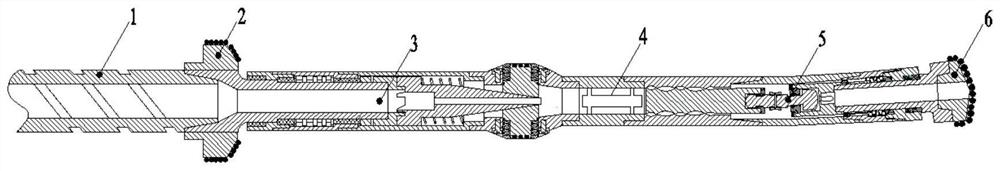

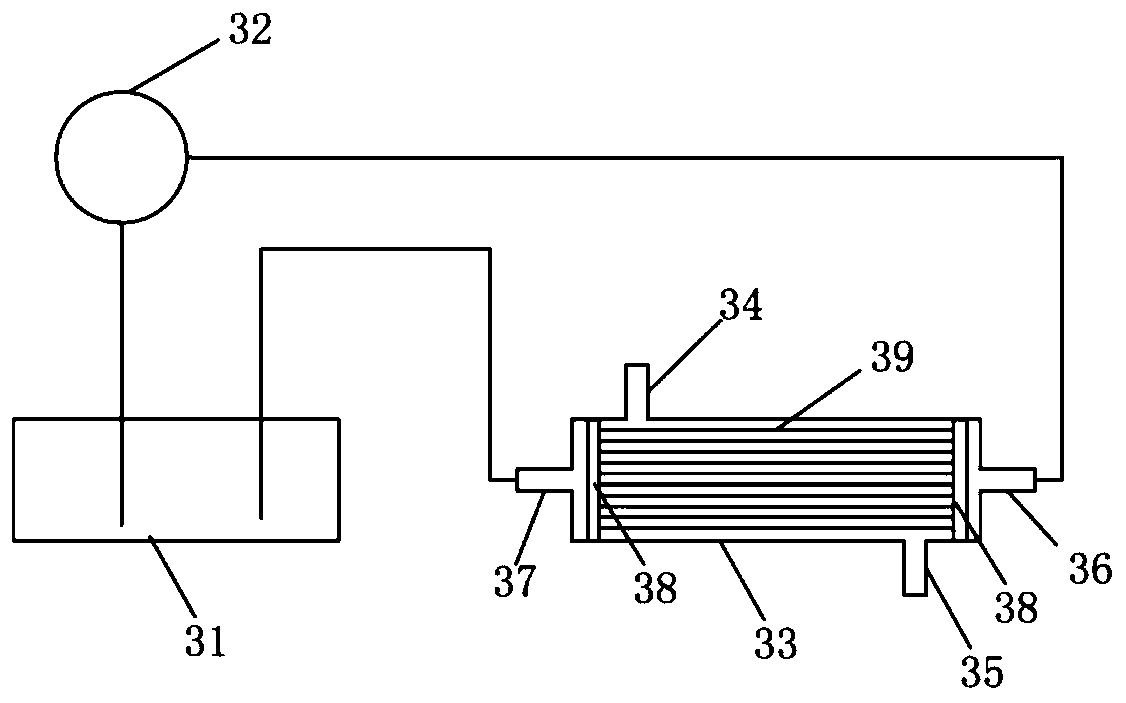

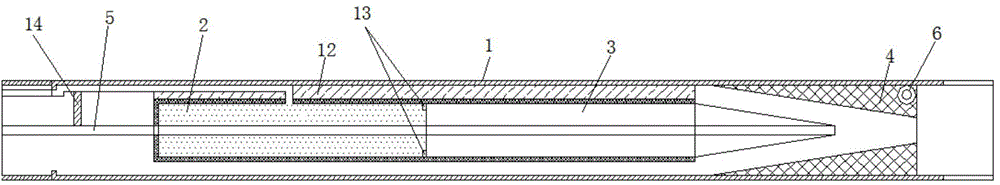

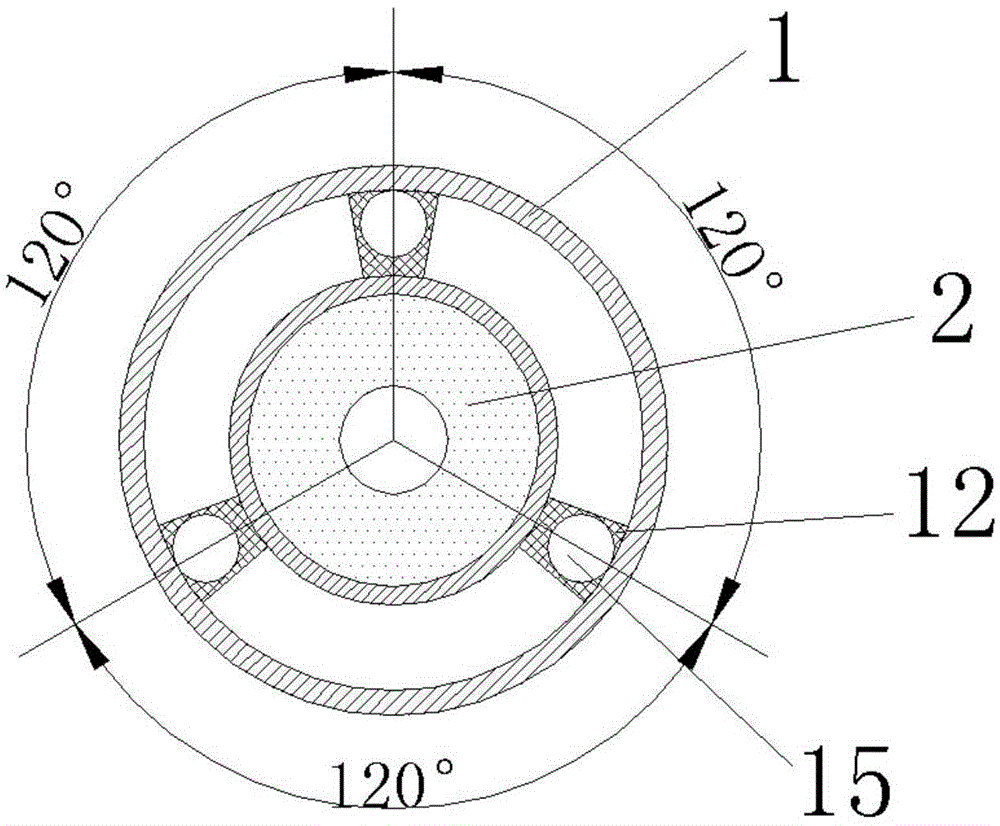

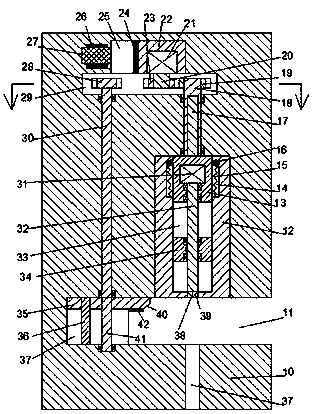

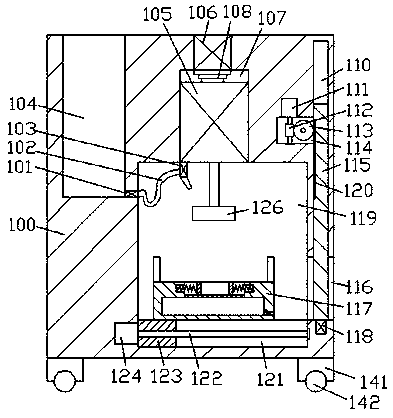

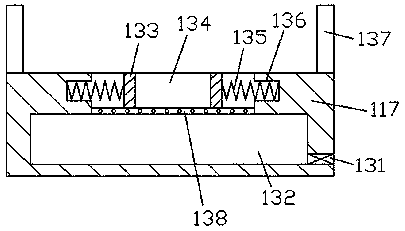

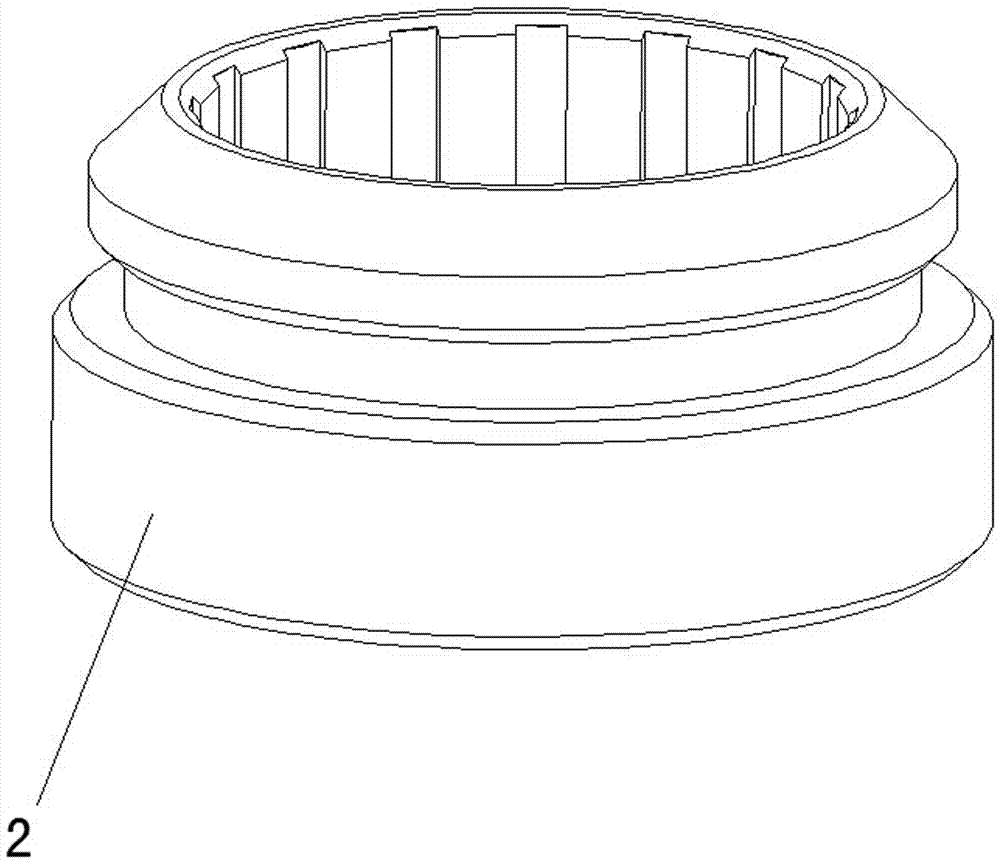

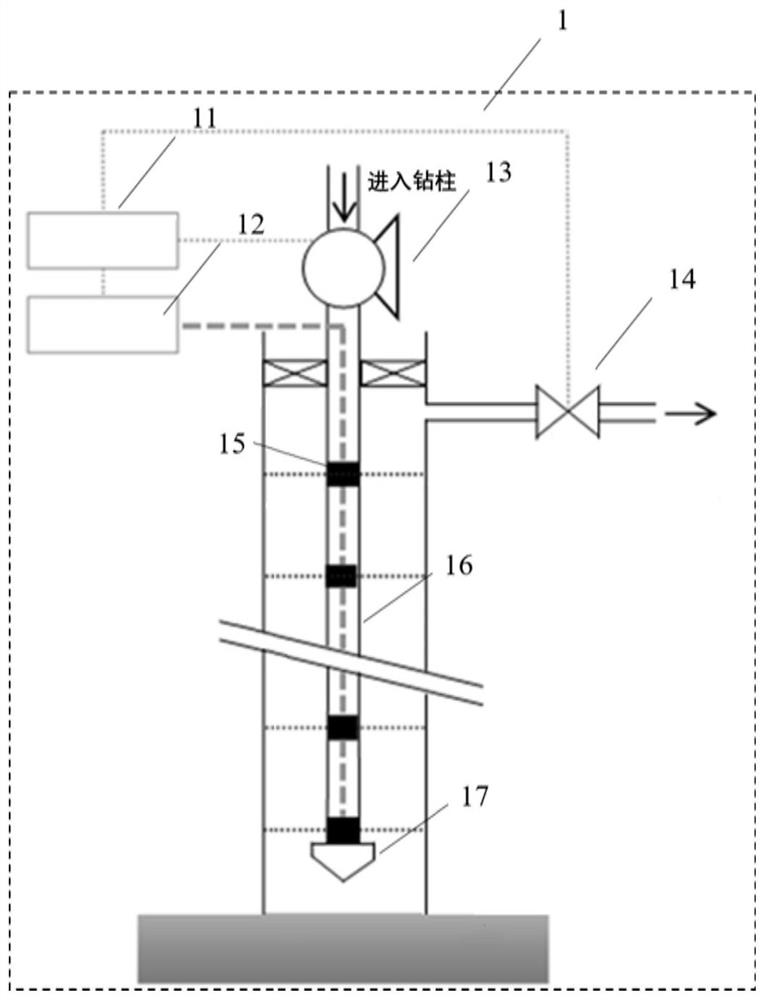

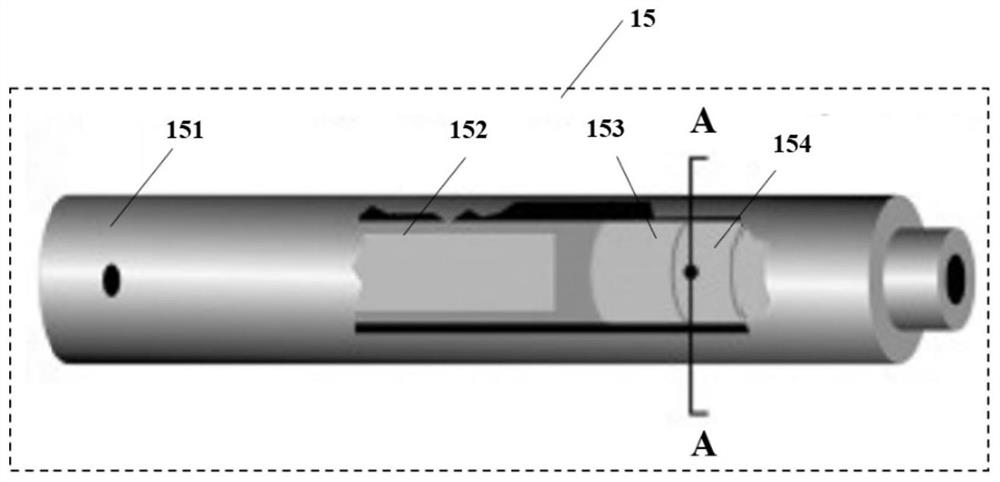

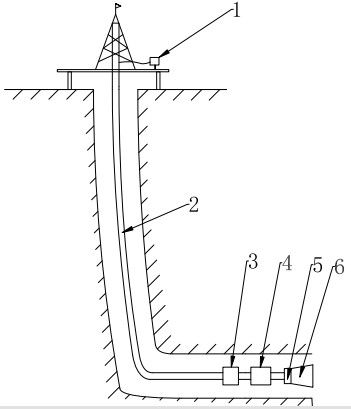

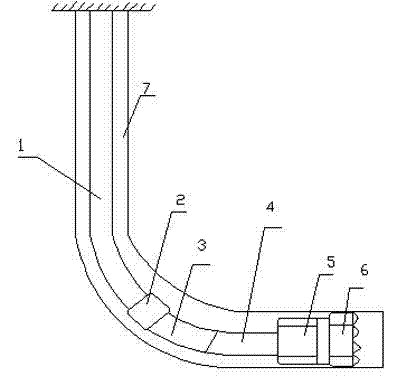

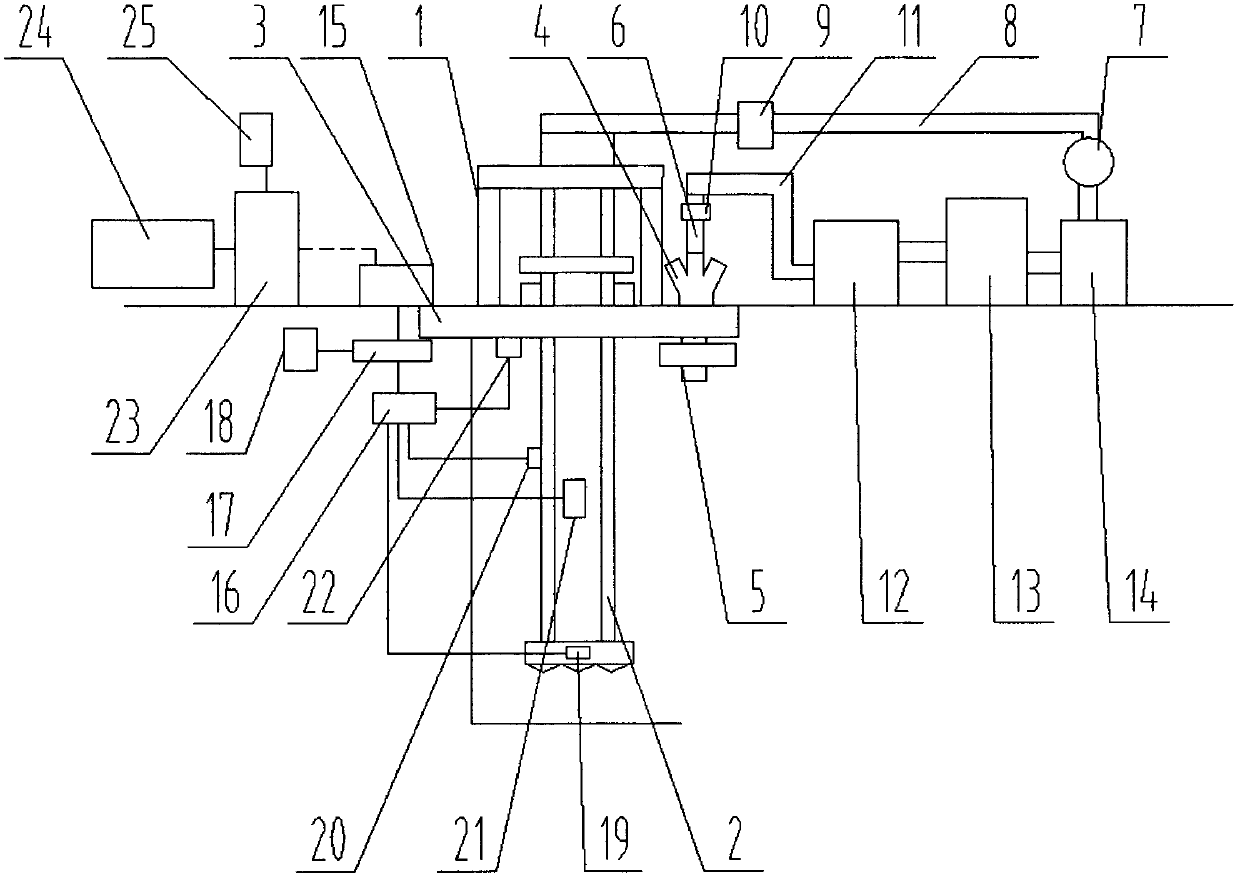

A Drilling Pressure Control System

The invention provides a drilling pressure control system and relates to the technical field of oil drilling. The drilling pressure control system comprises a drilling device, a wellhead device, a drilling fluid circulating system and a drilling pressure control module, wherein the drilling device comprise a drill rod rack (1) and a drill rod mechanism (2); the drill rod mechanism (2) is erected on a wellhead through the drill rod rack (1); the well head device comprises a wellhead safety base (3), a wellhead four-way joint (4), a wellhead blowout prevention device (5) and a wellhead slurry outlet pipe (6); the wellhead safety base (3) is circular ring-shaped and is mounted on the wellhead; a drilling fluid circulating outlet is formed in the wellhead safety base (3). The drilling pressure control system provided by the invention is reasonable in structural design and simple and quick in operation and can perform real-time quantitative monitoring on drilling pressure under an oil and gas well and control each electromagnetic valve through a program so as to adapt to various unstable factor caused by downhole pressure change and greatly improve the drilling safety, thereby having a practical value.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com