A kind of survey hole sampling device and control method

A sampling device and component technology, applied in the field of survey hole sampling device and control, can solve the problems of hole wall soil friction and disturbance, low core efficiency, easy to cause hole collapse, etc., so as to improve the degree of construction automation and improve construction efficiency , to avoid the effect of collapsing and leaking slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

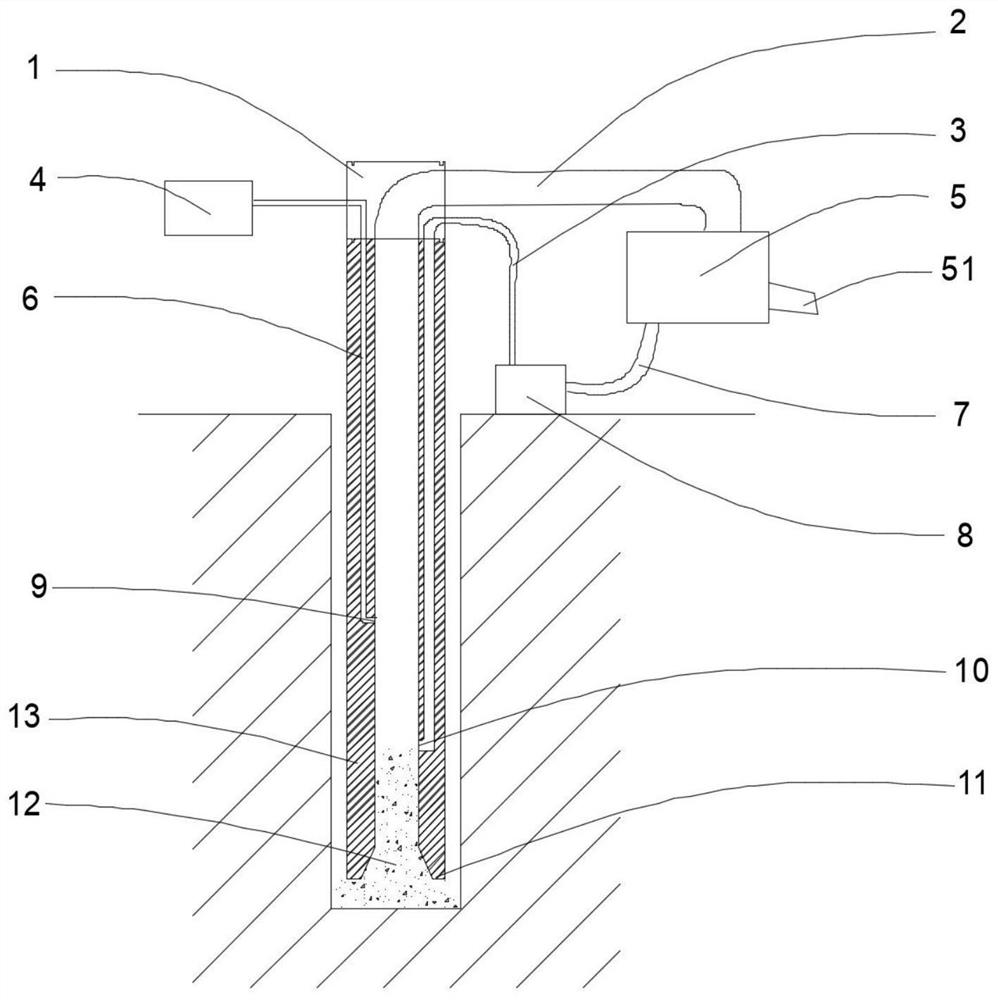

[0030] like figure 1 As shown, the survey hole sampling device of the present invention is a gas-liquid mixed alum backwashing device. The taken out solid-liquid mixture is precipitated and backwashed by using alum as a flocculant in a sedimentation tank. The survey hole sampling device includes a drilling component, a high pressure gas lift component, a high pressure slurry feeding component, a sedimentation separation component and a connection conversion component;

[0031] Wherein, the cutting and drilling assembly is connected with the connection conversion assembly, and the force is applied through the connection conversion assembly;

[0032] The high-pressure gas l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com