While-drilling jam release device for intelligent drilling

A drilling and jam-releasing technology, which is applied in earthwork drilling, wellbore/well components, etc., can solve problems such as mud bag sticking accidents, achieve the effects of reducing drilling costs, improving drilling safety, and reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

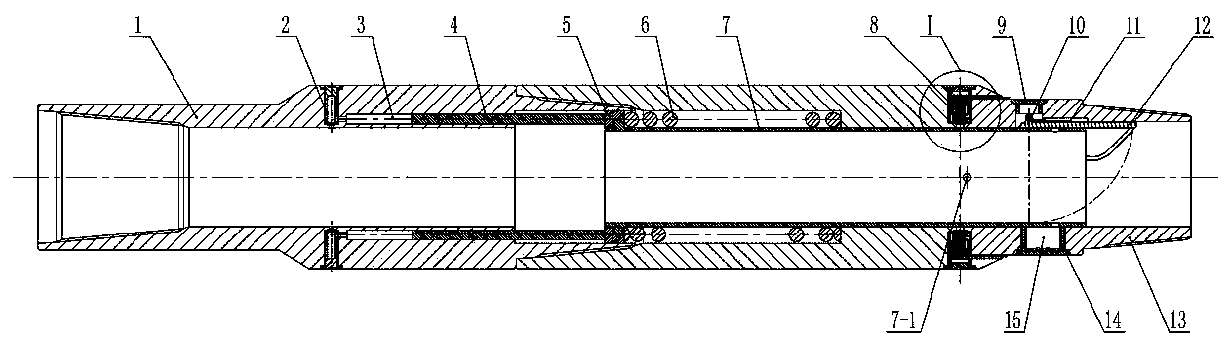

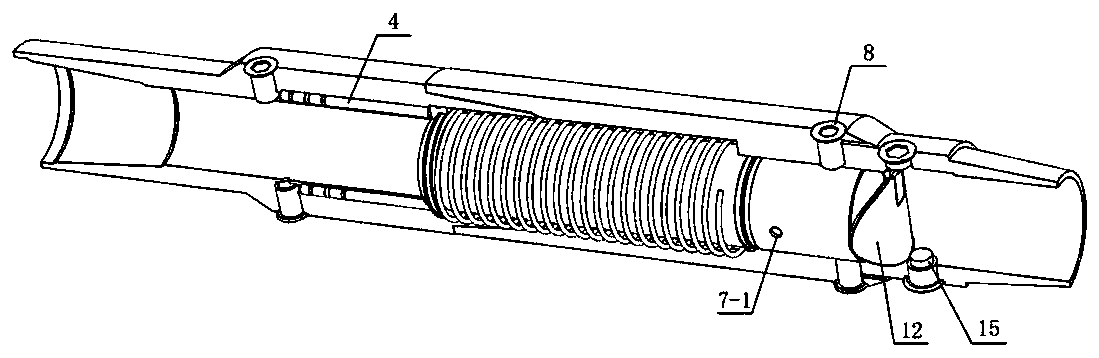

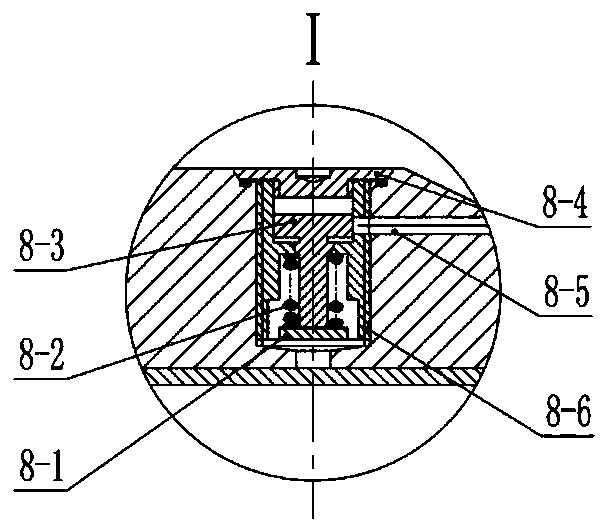

[0017] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 , figure 2 , image 3 As shown, the intelligent drilling while drilling jam release device of the present invention is mainly composed of an upper joint 1, a lower joint 13, a driving assembly, a liquid spray assembly 8, a locking assembly and a main body intercepting assembly. The tail of the upper joint 1 is connected to the lower joint through threads 13 end connection; the driving assembly is composed of a driving assembly solenoid valve 2, a plunger 4, a spring 6, a central tube 7 and a stopper 5, and the driving assembly solenoid valve 2 is fixed on the upper joint 1 through threaded connection; the plunger 4 passes through the gap Cooperate and install in the hydraulic cavity 3 of the upper joint 1; the end of the lower joint 13 is equipped with a spring 6 to cooperate through the gap; the liquid spray as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com