Near-horizontal pressurized directional drilling equipment and method for complex fractured formations in underground coal mines

A directional drilling and directional drilling technology, applied in drilling equipment and methods, directional drilling, drilling equipment and other directions, can solve the problems of high safety risk, easy instability and damage of the hole wall, low porosity, etc., to improve the control accuracy, The effect of improving the stability of the hole wall and improving the anti-blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

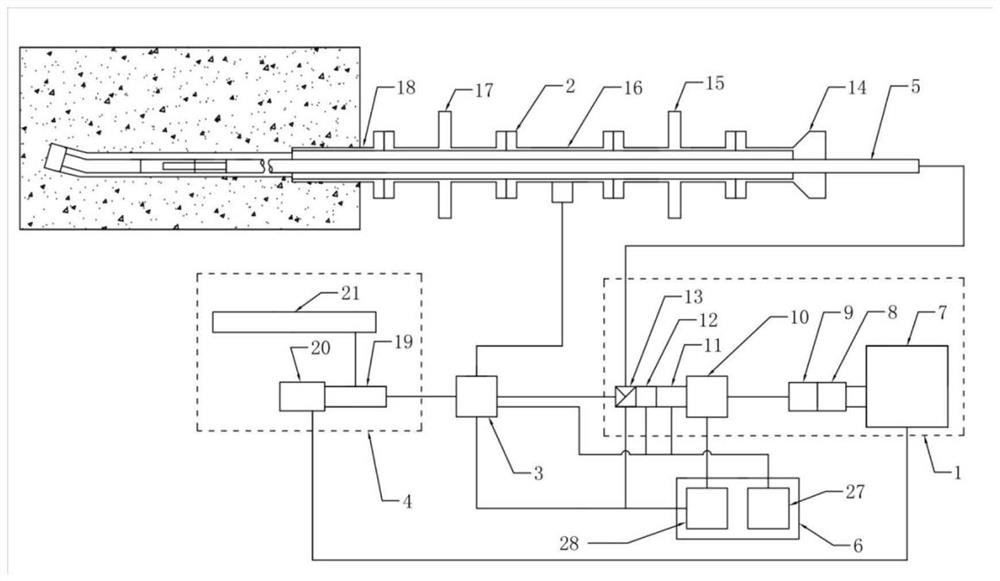

[0052] see figure 1 , figure 2 , the near-horizontal pressurized directional drilling equipment for complex broken formations in underground coal mines of the present invention includes a flushing fluid circulation system 1, an orifice sealing system 2, a throttling pressurization system 3, a contaminated flushing fluid treatment system 4, and a directional drilling tool assembly 5 and monitoring control system6.

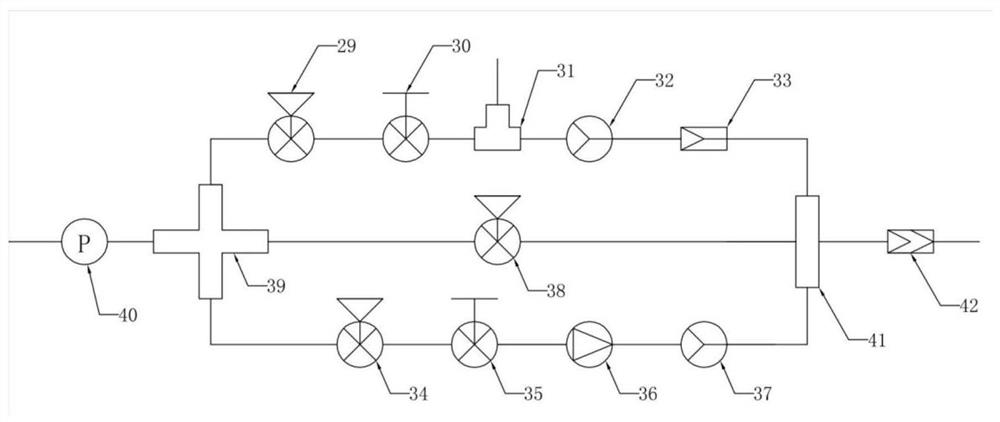

[0053] The flushing liquid circulation system 1 is composed of flushing liquid tank 7, butterfly valve 8, filter 9, flushing liquid pump 10, liquid supply flow measurement device 11, liquid supply pressure measurement device 12, flow channel switching valve 13, and is used to provide drilling The high-pressure flushing liquid that enters and pressurizes the hole wall, and the output flow of the flushing liquid pump 10 should be steplessly adjustable.

[0054] The orifice sealing system 2 is composed of an annular sealing device 14, a ram BOP A15, a sealing tee 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com