A Drilling Pressure Control System

A drilling and drilling fluid technology, applied in the field of drilling pressure control system, can solve the problems of not considering the balance between bottom hole pressure and formation pressure, complex matching of devices and instruments, and difficulty in popularization and application, so as to achieve good practical value and improve drilling safety Sex, structural design and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

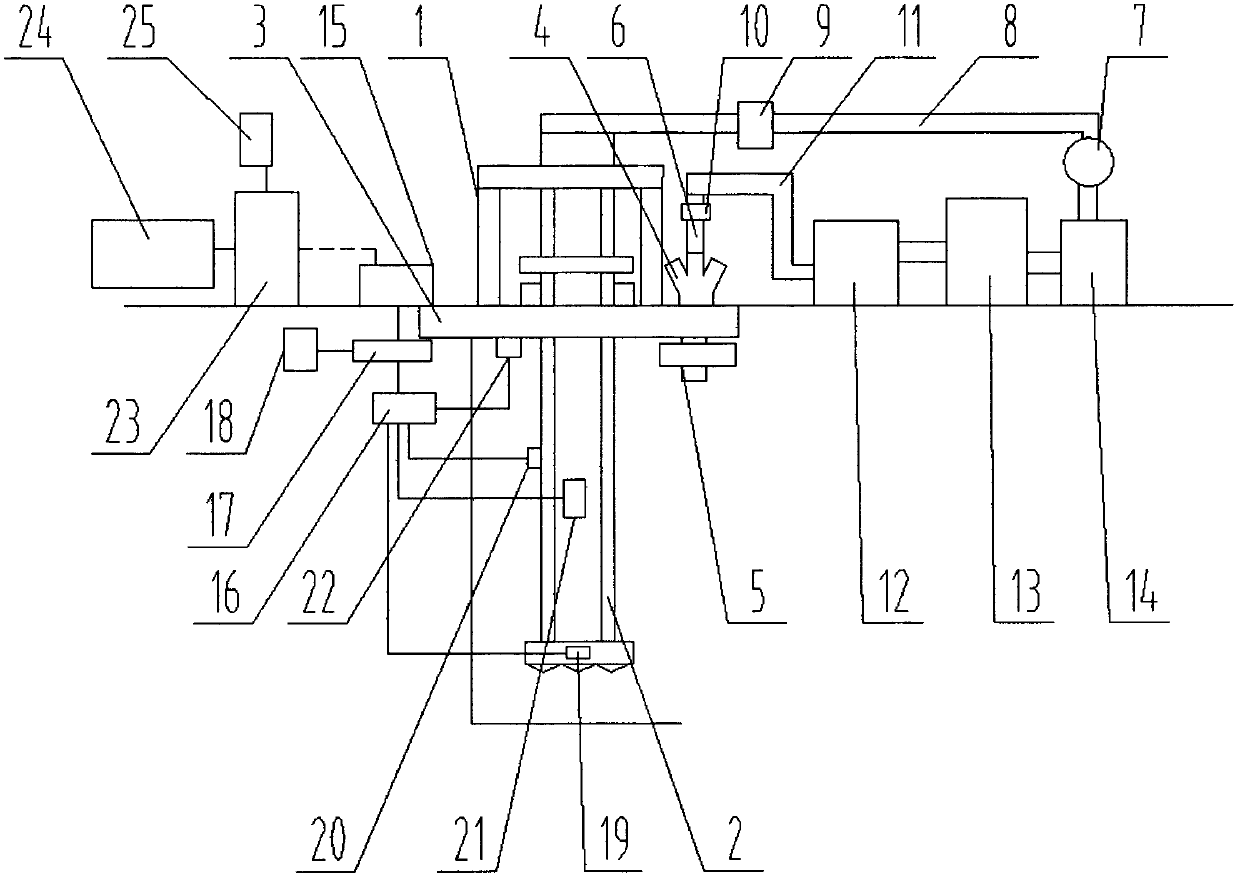

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the present invention includes a drilling device, a wellhead device, a drilling fluid circulation system and a drilling pressure control module. The drilling device includes a drill rod frame 1 and a drill rod mechanism 2. The drill rod mechanism 2 passes through the drill rod Erected at the wellhead, the wellhead device includes a wellhead safety base 3, a wellhead cross 4, a wellhead blowout preventer 5 and a wellhead slurry pipe 6, and the wellhead safety base 3 is installed at the wellhead, and the wellhead safety base 3 is a round Annular, the wellhead safety base 3 is provided with a drilling fluid circulation outlet, the wellhead cross 4 is sealed and installed at the center hole of the wellhead safety base 3, and the wellhead blowout preventer 5 is installed at the bottom of the wellhead cross 4 , the wellhead grouting pipe 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com