Underground coal mine directional drilling and reaming integrated drilling tool and directional drilling and reaming-while-drilling method

A directional drilling and casing technology, applied in drilling equipment and methods, directional drilling, drill bits, etc., can solve the problems of low efficiency of secondary large-diameter reaming, small primary hole diameter, and difficulty in forming holes in broken formations. Achieve the effect of avoiding tripping and rotary reaming operations, broadening the applicable formation range, and improving the efficiency of drilling and breaking rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

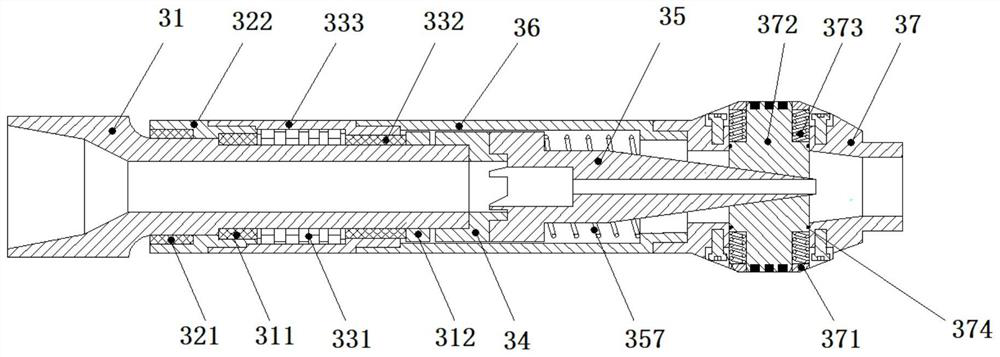

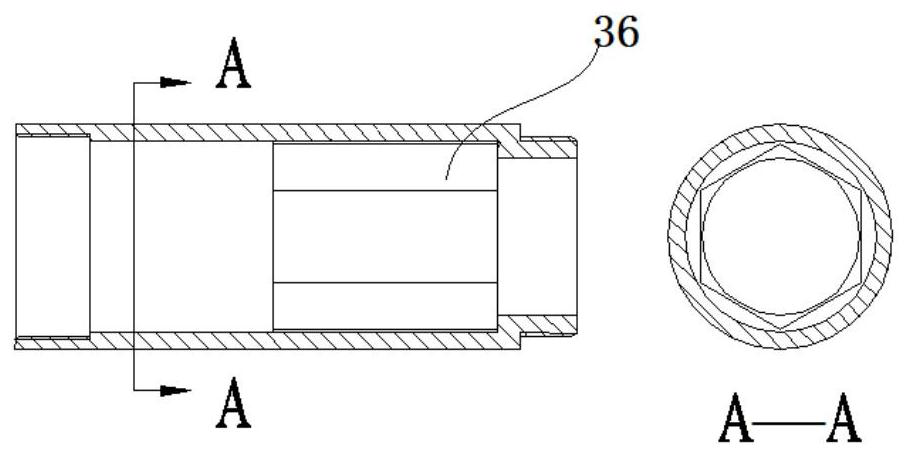

[0055] This embodiment provides a drilling state switching device, such as Figure 2 to Figure 7 As shown, it includes a transmission shaft 31, a bearing group A and a bearing group B that are sleeved on the outer wall of the transmission shaft 31 and are connected coaxially in sequence, a torsion disc 34 that is installed at the end of the transmission shaft 31 and can rotate with the transmission shaft 31, and a transmission shaft. The twist plate 34 is coaxially fitted with a piston 35 that can move axially, a piston housing 36 that is sleeved outside the piston 35 and can rotate synchronously with the piston 35, and the two ends of the piston housing 36 are respectively connected to the bearing group B and the fins The casing 37 ; the drive shaft 31 , the twist disc 34 , the piston 35 and the fin casing 37 are all connected through the center.

[0056] The piston 35 includes an integral piston end 351, a piston connecting portion 352, a tapered piston tip 353, a piston cen...

Embodiment 2

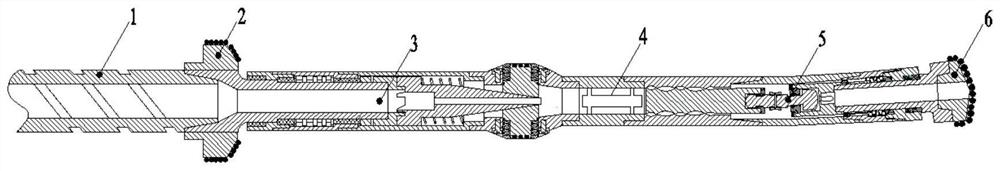

[0068] This embodiment provides an integrated drilling tool for directional drilling and expansion in coal mines, such as figure 1 As shown, it includes the drilling state switching device 3 in Embodiment 1, and also includes a sliding directional drilling tool and a rotary reaming drill, and the sliding directional drilling tool, the drilling state switching device 3 and the rotary reaming drill are connected in sequence.

[0069] The sliding directional drilling tool includes a sequentially connected measurement-while-drilling probe tube 4 , a single-curved screw motor 5 and a directional drill bit 6 , and the measurement-while-drilling probe tube 4 is connected to a fin housing 37 .

[0070] The rotary reaming drilling tool includes a special-shaped drill rod 1 and a reaming drill bit 2. The outer wall of the special-shaped drill rod 1 is provided with a hyperboloid spiral groove. Connect the installation end of the transmission shaft, and the reaming drill bit 2 is set out...

Embodiment 3

[0075] This embodiment provides a method for directional drilling while drilling in underground coal mines, such as Figure 8 As shown, the method includes the following steps:

[0076] Step 1: Connect drilling tools: After completing the construction of the orifice casing section, install the directional drill bit, single-curved screw motor, measurement-while-drilling probe, drilling state switching device, reaming bit and special-shaped drill pipe in sequence, and use the drilling machine to connect The directional drilling and expansion integrated drilling tool is lowered to a distance of 0.5m from the bottom of the hole;

[0077]Step 2: Adjust the direction of directional drilling: keep the orifice mud pump in the closed state, the piston contacts and engages with the torsion disc under the action of spring A, and the wings are retracted under the push of spring B; use the measurement while drilling probe to measure the drilling Hole trajectory space parameters and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com