Adjustable gas directional drilling equipment and method for crushed soft coal seam in underground coal mine

A technology of directional drilling and soft coal seam, applied in directional drilling, construction, etc., can solve the problem that the wireless measurement while drilling system does not meet the strong vibration and the use environment of coal seam, the risk of spontaneous combustion of coal seam, etc., to improve the slag discharge effect and improve the signal Transmission efficiency, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

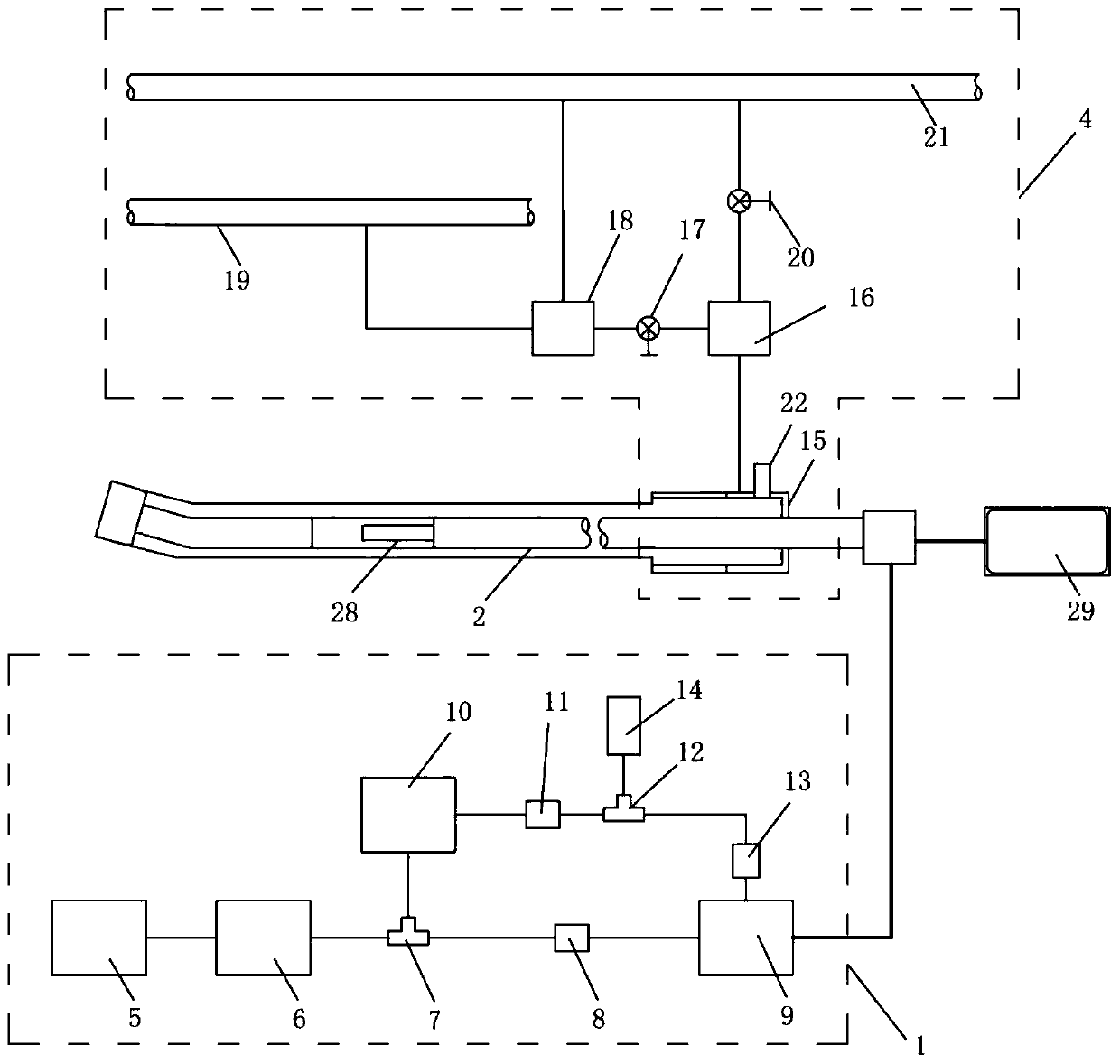

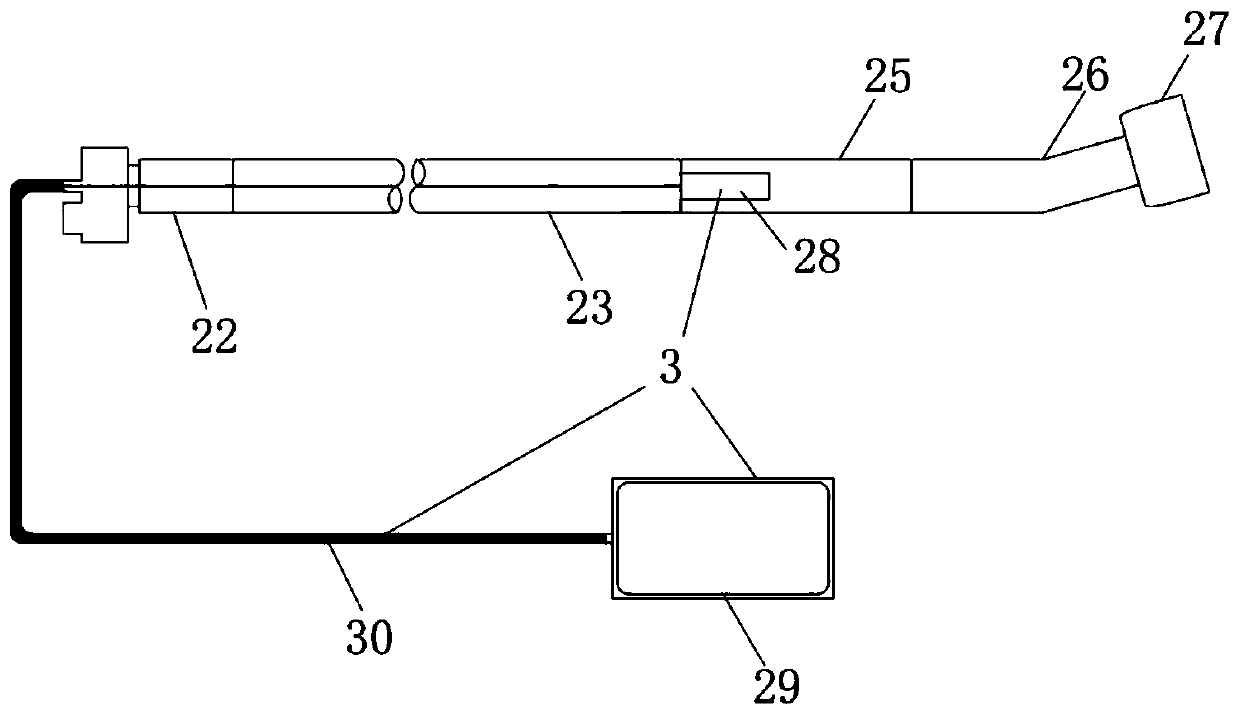

[0032] see figure 1 , shows the adjustable gas directional drilling equipment of the present invention for the broken soft coal seam under the coal mine.

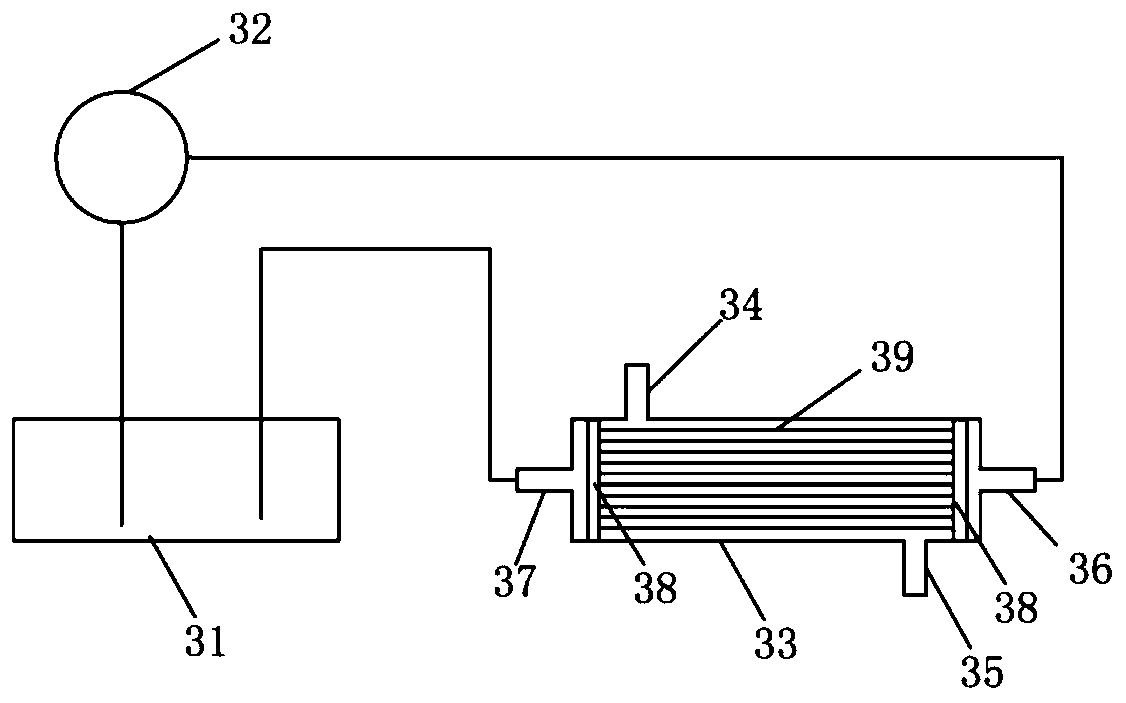

[0033]The adjustable gas directional drilling equipment for crushed and soft coal seams in underground coal mines includes devices such as an orifice mixed gas supply system 1, a directional drilling tool assembly 2, a mining wired measurement while drilling device 3, and an orifice exhaust gas treatment system 4. Port mixed air supply system 1 can provide compressed air and nitrogen for drilling respectively, and is composed of mine mobile air compressor 5, air cooling device 6, first air path switching valve 7, first check valve 8, lubrication control device 9. The first nitrogen separation device 10, the oxygen concentration sensor 11, the second gas circuit switching valve 12, the second one-way valve 13, the vent valve 14, etc., among which the mining mobile air compressor 5, the air cooling device 6, The first gas pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com