Redressing-while-drilling machine for drilling engineering and redressing method

A technology of drilling engineering and reamer, which is applied in the direction of drilling equipment and methods, drilling equipment, drill bits, etc., and can solve problems such as casing running and electrical measurement resistance, formation instability, and borehole size reduction, etc., to achieve Eliminate complications, improve drilling safety, and improve regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

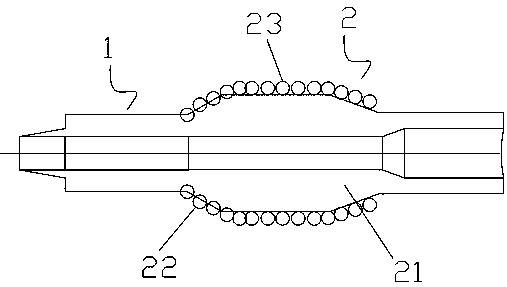

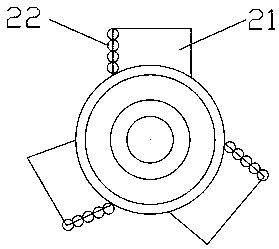

[0016] like figure 1 , 2 As shown, the present invention is a reamer while drilling for drilling engineering, which includes a cylindrical body 1 and a helical blade 2, and three blades 2 are arranged and fixed on the cylindrical body 1 evenly.

[0017] Wherein, the blade 2 includes a blade body 21, a PDC composite sheet cutting tooth 22 and a gauge flat lying tooth 23, and 13-17 PDC composite sheet cutting teeth are evenly distributed on the surface of each blade body 21 22. The gauge flat lying teeth 23 are evenly distributed on the gauge part of the blade body 21 .

[0018] In this embodiment, the cutting edge value of the cutting teeth of the above-mentioned PDC composite sheet is 13.7-14.6%. The above cylindrical body 1 is integrally formed, with an outer diameter of 125-128 mm and an inner diameter of 75-78 mm.

[0019] The present invention also discloses a reamer-while-drilling method for drilling engineering, using the above-mentioned reamer-while-drilling device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com