enhance co 2 Chemical Auxiliaries for Oil Recovery in Gas Drive Process

A technology of chemical additives and recovery factor, applied in chemical instruments and methods, mining fluids, earthwork drilling and production, etc., can solve problems such as limited data, insufficient theoretical and practical research on chemical agent structure, and influence on method development, etc., to achieve Improve mutual solubility, improve crude oil rheology and recovery factor, and apply to a wide range of formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

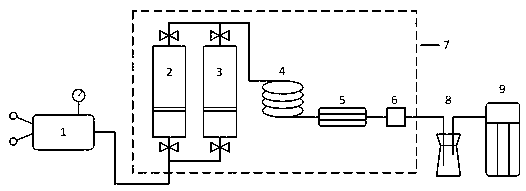

Method used

Image

Examples

Embodiment 1

[0033] Put 30g of n-hexyl acrylate, 40g of formamide and 30g of xylene in a beaker to prepare a mixing aid, stir and ultrasonically make it fully and evenly mixed, and let it stand for 24 hours before use.

[0034] The chemical auxiliary agent described in this embodiment adopts the injection mode and CO 2 Mix and infuse.

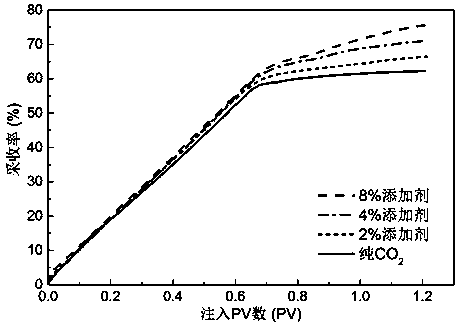

[0035] During the experiment, first use the back pressure valve to control the system pressure to 24MPa, after the system is balanced, inject CO2 at 0.17ml / min 2 At the same time, the auxiliary agent is injected at a rate of 0.001508ml / min. The injection speed corresponds to the mass of the auxiliary agent in the injected gas as CO 2 2% of the mass. During the injection process, the produced oil and gas fluids were measured every 15 minutes, and the phase state and color changes of the fluids were observed through the observation window until the injected gas volume reached 1.2PV and the experiment was stopped.

[0036] Experimental results, such as fig...

Embodiment 2

[0038] Put 30g of n-hexyl acrylate, 40g of formamide and 30g of xylene in a beaker to prepare a mixing aid, stir and ultrasonically make it fully and evenly mixed, and let it stand for 24 hours before use.

[0039] The chemical auxiliary agent described in this embodiment adopts the injection mode and CO 2 Mix and infuse.

[0040] During the experiment, first use the back pressure valve to control the system pressure to 24MPa, after the system is balanced, inject CO2 at 0.17ml / min 2 At the same time, the auxiliary agent is injected at a rate of 0.003016ml / min. The injection speed corresponds to the mass of the auxiliary agent in the injected gas as CO 2 4% of the mass. During the injection process, the produced oil and gas fluids were measured every 15 minutes, and the phase state and color changes of the fluids were observed through the observation window until the injected gas volume was 1.2PV and the experiment was stopped.

[0041] Experimental results such as figure 2...

Embodiment 3

[0043] Put 30g of n-hexyl acrylate, 40g of formamide and 30g of xylene in a beaker to prepare a mixing aid, stir and ultrasonically make it fully and evenly mixed, and let it stand for 24 hours before use.

[0044] The chemical auxiliary agent described in this embodiment adopts the injection mode and CO 2 Mix and infuse.

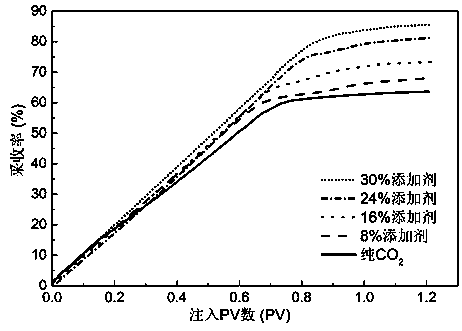

[0045] During the experiment, first use the back pressure valve to control the system pressure to 24MPa, after the system is balanced, inject CO2 at 0.17ml / min 2 At the same time, the auxiliary agent is injected at a rate of 0.006032ml / min. The injection speed corresponds to the mass of the auxiliary agent in the injected gas as CO 2 8% of the mass. During the injection process, the produced oil and gas fluids were measured every 15 minutes, and the phase state and color changes of the fluids were observed through the observation window until the injected gas volume reached 1.2PV and the experiment was stopped.

[0046] Experimental results, such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com