Prefabricated cast-in-place pile and pile forming method thereof

A technology of prefabricated piles and cast-in-place piles, which can be applied to sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of difficult pile sinking, long pile construction time, and high construction cost. High, the effect of improving the shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

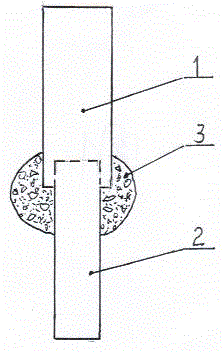

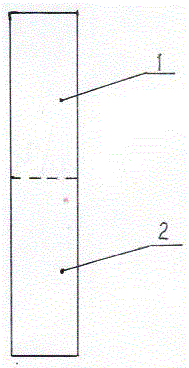

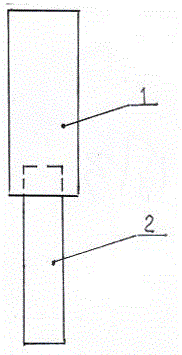

[0015] Examples, see attached figure 1 , 2 , the diameter of the upper cast-in-place pile 1 of the prefabricated cast-in-place pile is greater than the diameter of the lower precast pile 2, and the cast-in-place pile 1 wraps the top of the precast pile 2, and the connection between the precast pile 2 and the cast-in-place pile 1 is provided with or without concrete according to design requirements The filler 3 can also be a cement mixture filler, or the diameter of the upper cast-in-situ pile 1 and the lower prefabricated pile 2 is the same. The pile-forming method of prefabricated cast-in-place piles is as follows, refer to the attached image 3 , pile-forming method A: step Aa, move pile machine, align pile machine inner tube drilling tool 4 and outer tube drilling tool 5 to the pile position, adjust the positions of the front, back, left, and right sides of the drilling rig, so that the main rod of the drilling rig and the outer tube drilling tool 5 The front, rear, left,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com