A gas pipeline liquid metal sealing valve for high temperature environment

A gas pipeline, liquid metal technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of easy anastomosis, poor sealing, etc., to achieve low volatility, large specific gravity, and solve the effect of absolute sealing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

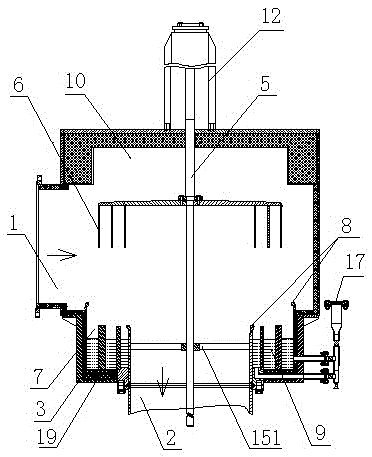

[0030] like figure 1 As shown, a gas pipeline liquid metal sealing valve for high temperature environment includes a valve body 3 provided with an air inlet 1 and an air outlet 2, the valve body 3 is pierced with a valve stem 5, and the upper part of the valve stem 5 is Connect the valve rod driving device 12, the valve rod driving device 12 is an air cylinder or hydraulic cylinder, the lower part of the valve rod 5 is connected to the isolation cover structure, and the isolation cover structure includes a three-layer isolation cover unit 6, the valve body 3 There are three groups of sealing groove units 7 arranged at the bottom, liquid metal 9 is injected into the sealing groove units 7, an anti-splash ring 8 is arranged at the upper end of the sealing groove units 7, a groove 10 is arranged inside the valve body 3, and the The size of the groove 10 is larger than the maximum size of the isolation cover structure; the valve body 3 is provided with a guide assembly 151 for the...

Embodiment 2

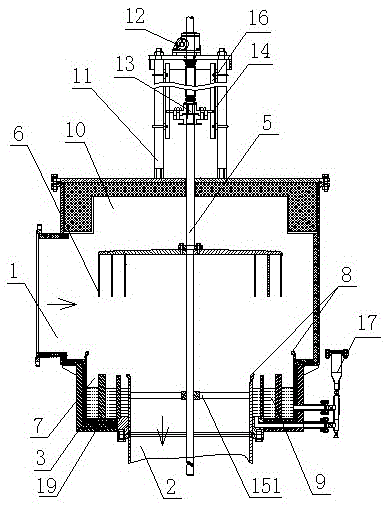

[0039] like figure 2 As shown, a gas pipeline liquid metal sealing valve for high temperature environment includes a valve body 3 provided with an air inlet 1 and an air outlet 2, the valve body 3 is pierced with a valve stem 5, and the upper part of the valve stem 5 is Connect the valve stem driving device 12, the lower part of the valve stem 5 is connected to the isolation cover structure, the isolation cover structure includes a three-layer isolation cover unit 6, and three sets of sealing groove units 7 are arranged at the bottom of the valve body 3, and the sealing The tank unit 7 is filled with liquid metal 9, the upper end of the sealing tank unit 7 is provided with a splash guard ring 8, and the inner side of the valve body 3 is provided with a groove 10, and the size of the groove 10 is larger than the maximum size of the isolation cover structure . The valve stem driving device 12 is arranged on the sleeve 11 on the valve body 3, the output end of the valve stem dr...

Embodiment 3

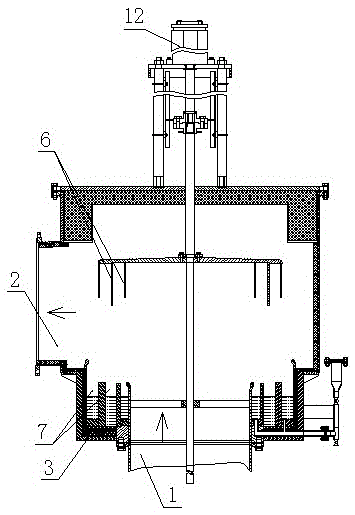

[0042] like image 3 As shown, a gas pipeline liquid metal sealing valve for high-temperature environments differs from Embodiment 1 or 2 in that: the sealing groove units 7 are arranged in random order, and the vertical size of the isolation cover unit 6 is adapted to the sealing groove unit 7, the air inlet 1 is in the lower position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com