Low-surface treatment rusty rust inhibiting primer for hot galvanized steel

A low surface treatment, rust and rust prevention technology, applied in the field of paint, can solve the problems of neglect of environmental protection, excessive use of xylene, environmental and human health hazards, etc., achieve good gloss, reduce environmental and human harm, reduce Effects of cost and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

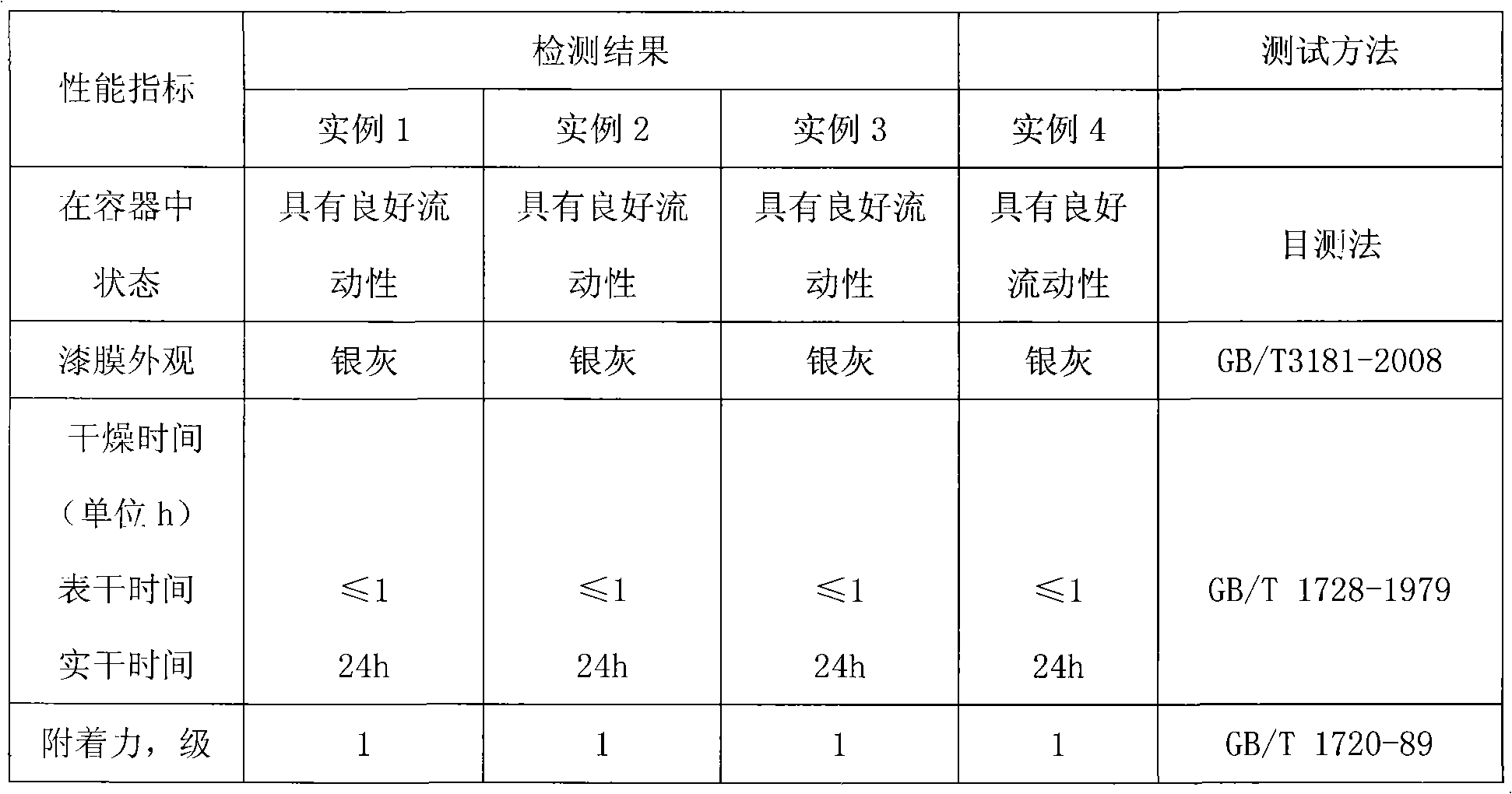

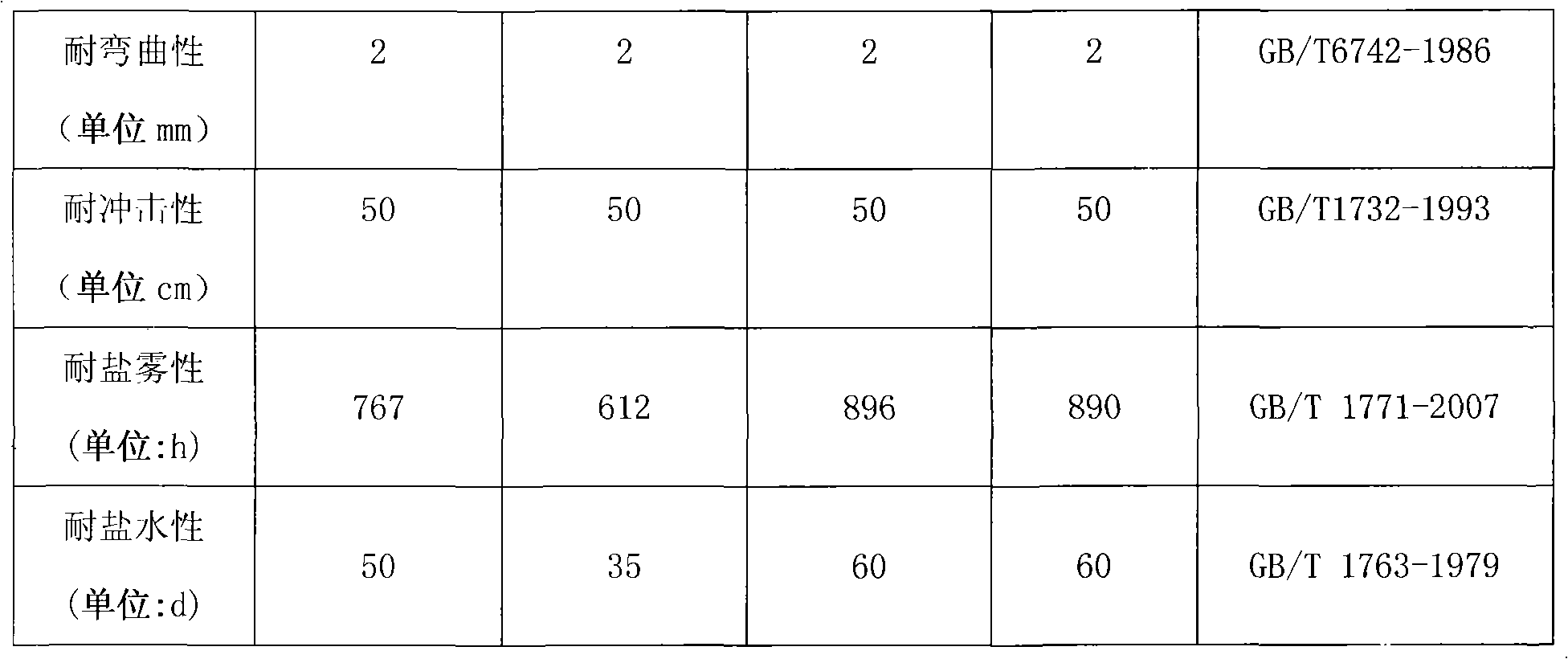

Examples

Embodiment 1

[0035] The surface of the hot-dip galvanized steel provided by the present embodiment uses a low surface treatment band rust primer, wherein the band rust primer includes A component and B component by 100 parts by weight;

[0036] A component: 15 parts of film-forming resin solution, 30 parts of pigment, 4 parts of rust conversion agent and 1 part of organic bentonite are obtained by mixing, stirring and grinding; B component: 20 parts of mixed curing agent and 30 parts of mixed solvent; The volume ratio of component A to component B is 5.5:1.

[0037] The film-forming resin solution is composed of the following components by mass ratio: 60% by mass percent of epoxy resin dilution 15, 15% by mass percent of polyvinyl butyral solution 60, epoxy-modified organic Silicone resin 15, amino resin 10.

[0038] Pigments: zinc phosphate, modified aluminum tripolyphosphate, zinc borate and zinc flakes.

[0039] Rust converters: phosphoric acid, tannic acid; acetone, butanone; nickel ...

Embodiment 2

[0046] The surface of the hot-dip galvanized steel provided by the present embodiment uses a low surface treatment band rust primer, wherein the band rust primer includes A component and B component by 100 parts by weight;

[0047] A component: 40 parts of film-forming resin solution, 10 parts of pigment, 12 parts of rust conversion agent and 0.5 parts of organic bentonite are obtained by mixing, stirring and grinding; B component: 22 parts of mixed curing agent and 15.5 parts of mixed solvent; The volume ratio of component A to component B is 4.5:1.

[0048]The film-forming resin solution is composed of the following components by mass ratio: 60% by mass percent of epoxy resin dilution 45, 15% by mass of polyvinyl butyral solution 30, epoxy modified organic Silicone resin 15, amino resin 10.

[0049] Pigments: zinc phosphate, modified aluminum tripolyphosphate, zinc borate and zinc flakes.

[0050] Rust converters: phosphoric acid, tannic acid, citric acid; alcohol, alkylph...

Embodiment 3

[0057] The surface of the hot-dip galvanized steel provided by the present embodiment uses a low surface treatment band rust primer, wherein the band rust primer includes A component and B component by 100 parts by weight;

[0058] A component: 20 parts of film-forming resin solution, 10 parts of pigment, 9 parts of rust conversion agent and 1 part of organic bentonite are obtained by mixing, stirring and grinding; B component: 25 parts of mixed curing agent and 35 parts of mixed solvent; The volume ratio of component A to component B is 5.5:1.

[0059] The film-forming resin solution is composed of the following components by mass ratio: 60% by mass percent of epoxy resin dilution 37, 15% by mass of polyvinyl butyral solution 60, epoxy-modified organic Silicone resin 2, amino resin 1.

[0060] Pigments: zinc phosphate, modified aluminum tripolyphosphate, zinc borate and zinc flakes.

[0061] Rust converters: tannic acid, stearic acid; ethanol, butanol; zinc nitrate.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com