Novel non-formaldehyde wood adhesive and preparation thereof

A wood adhesive and adhesive technology, which is applied in the preparation of adhesives, animal glue or gelatin, and protein adhesives, etc., can solve the problems of high price and difficult coating of protein glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

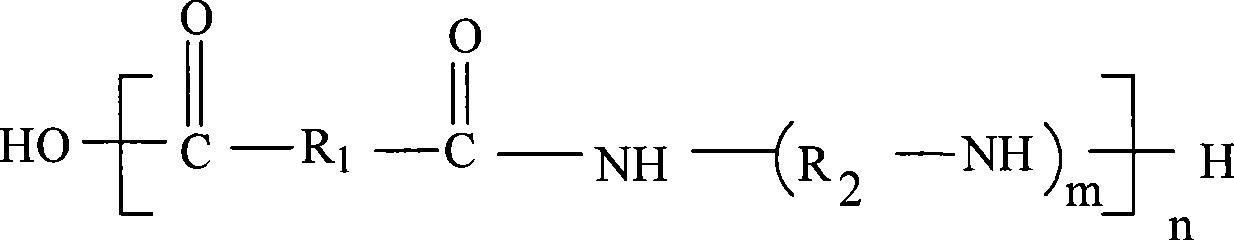

Image

Examples

Embodiment 1

[0068] Add 15 grams of soy protein isolate and 100 grams of water in an Erlenmeyer flask, then stir for 2 hours until the protein is completely dispersed in the water. The solution is used directly as an adhesive for wood bonding. The dry strength of the adhesive is 3.5MPa, but the wood damage rate is only 10%. According to the national standard GB / T17657-1999, the dry strength test of the adhesive is as follows: the five-layer poplar board is obtained through the processes of gluing, aging, cold pressing, and hot pressing. The cold pressing condition is 1.2MPa, 30 minutes. The hot pressing conditions were 140°C, 1 MPa and 80 sec / mm. The five-layer board was aged at room temperature for 24 hours, and then tested on a universal tensile machine. The wet strength of the five-layer board is obtained by soaking at 63°C for 3 hours, then cooling at room temperature for 10 minutes and immediately testing it on a universal tensile machine.

Embodiment 2

[0070]In an Erlenmeyer flask, add 100 grams of aqueous solutions of 20 grams of soybean powder and 5% sodium hydroxide, then stir for 2 hours until the soybean powder is completely dispersed in water. The mixture is used as an adhesive for wood bonding. The dry strength of the adhesive is 3.0MPa, but the wood damage rate is only 20%.

Embodiment 3

[0072] In an Erlenmeyer flask, add 100 grams of aqueous solutions of 20 grams of soybean powder and 5% sodium hydroxide, then stir for 2 hours until the soybean powder is completely dispersed in water. Add 0.2 g of epichlorohydrin and stir for 1 hour. The mixture is used as an adhesive for wood bonding. The dry strength of the adhesive is 4.2MPa, and the wood damage rate is only 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry strength | aaaaa | aaaaa |

| Dry strength | aaaaa | aaaaa |

| Dry strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com