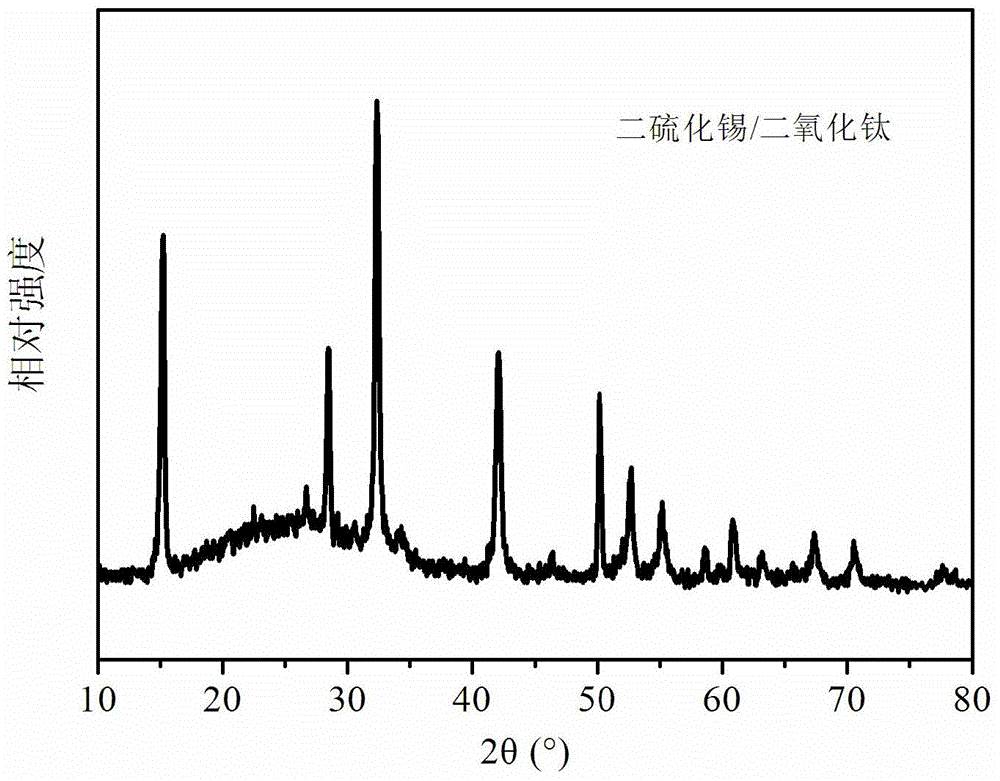

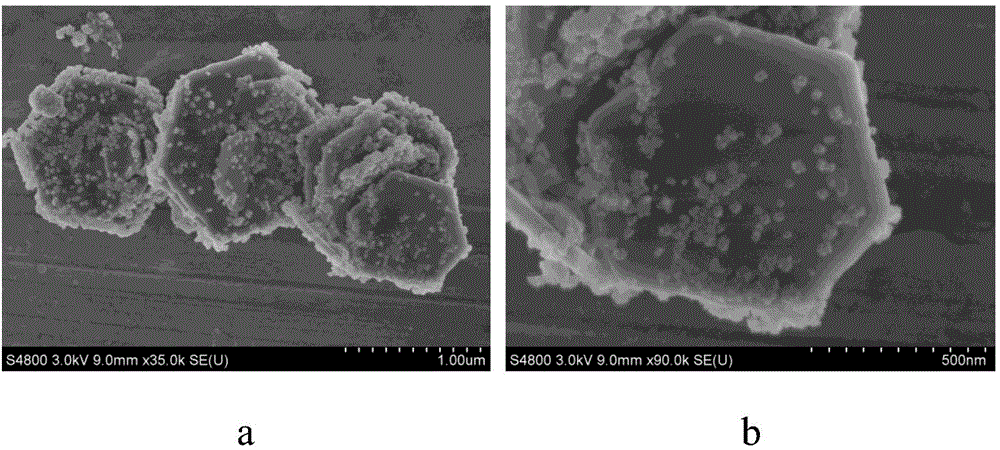

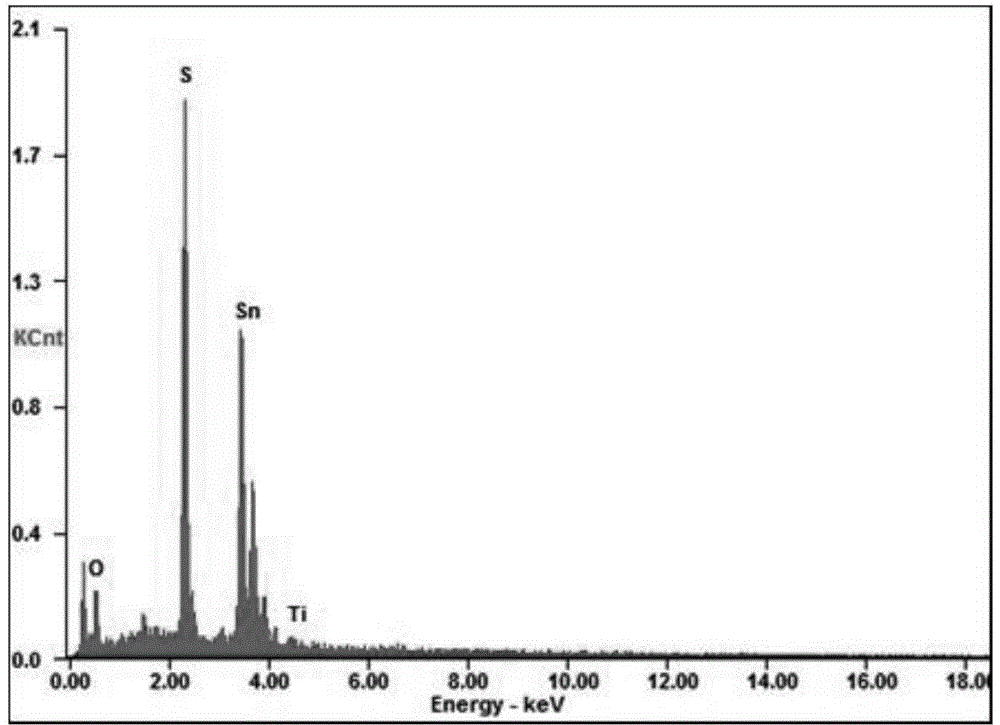

Tin disulfide/titanium dioxide compound photocatalyst and preparation method thereof

A tin disulfide, titanium dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the two semiconductor components are difficult to mix uniformly and cannot be formed. Tight and firm interface, high process control requirements, to achieve large-scale preparation, avoid self-aggregation, and high photocatalytic reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Add tin tetrachloride pentahydrate to deionized water and stir for 10 minutes. The mass ratio of tin tetrachloride pentahydrate to deionized water is 0.007:1 to obtain mixture A; under stirring, add thiourea to the prepared In mixture A, the mass ratio of thiourea to mixture A is 0.0075:1, stir for 20 minutes, and transfer the resulting solution to a reactor lined with polytetrafluoroethylene, and heat it hydrothermally at 160°C for 12 hours; the reaction is complete The latter solution was naturally cooled to room temperature, and the solution was centrifuged, and then washed with absolute ethanol and deionized water 3 times, and dried in an oven at 60~80℃ for 10 hours to obtain yellow tin disulfide powder; The prepared tin disulfide powder was dispersed in absolute ethanol, and 5 g of tin disulfide powder was added per liter of absolute ethanol, followed by ultrasonic dispersion for 30 minutes to obtain mixture B; adding butyl titanate to mixture B, butyl titanate The ...

Embodiment 2

[0056] Add tin tetrachloride pentahydrate to deionized water and stir for 13 min. The mass ratio of tin tetrachloride pentahydrate to deionized water is 0.005:1 to obtain mixture A; under stirring, add thiourea to the prepared In mixture A, the mass ratio of thiourea to mixture A is 0.0058:1, stir for 30 minutes, transfer the resulting solution to a reactor with a polytetrafluoroethylene lining, and heat it hydrothermally at 170°C for 16 hours; the reaction is complete The latter solution was naturally cooled to room temperature, and the solution was centrifuged, and then washed 4 times with absolute ethanol and deionized water, and dried in an oven at 65°C for 12 hours to obtain yellow tin disulfide powder; weigh the obtained Disperse the tin disulfide powder in absolute ethanol, add 7g tin disulfide powder per liter of absolute ethanol, and disperse ultrasonically for 40 minutes to obtain mixture B; add butyl titanate to mixture B, butyl titanate and mixture The mass ratio of...

Embodiment 3

[0059] Add tin tetrachloride pentahydrate to deionized water and stir for 17 min. The mass ratio of tin tetrachloride pentahydrate to deionized water is 0.0039:1 to obtain mixture A; under stirring, add thiourea to the prepared In mixture A, the mass ratio of thiourea to mixture A is 0.0044:1, stir for 45 minutes, and transfer the resulting solution to a reactor lined with polytetrafluoroethylene, and heat it hydrothermally at 180°C for 20 hours; the reaction is complete After the solution was naturally cooled to room temperature, the solution was centrifuged, and then washed with absolute ethanol and deionized water for 5 times, and dried in an oven at 75°C for 13 hours to obtain yellow tin disulfide powder; weigh the obtained product Disperse the tin disulfide powder in absolute ethanol, add 8g tin disulfide powder per liter of absolute ethanol, and ultrasonically disperse for 50 minutes to obtain mixture B; add butyl titanate to mixture B, butyl titanate and mixture The mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com