Wastewater treatment and recycling technology based on UV photocatalytic oxidation

A photocatalytic oxidation and wastewater treatment technology, which is applied in the directions of oxidized water/sewage treatment, illumination water/sewage treatment, water/sewage treatment, etc., to achieve the effect of low cost of treatment equipment, remarkable effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

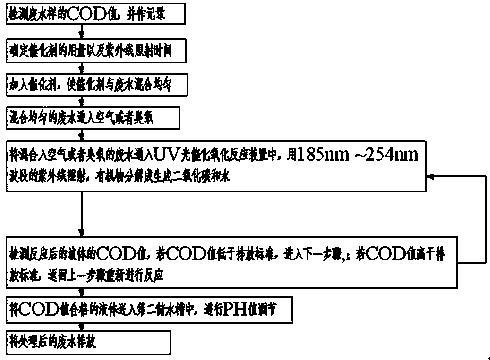

Method used

Image

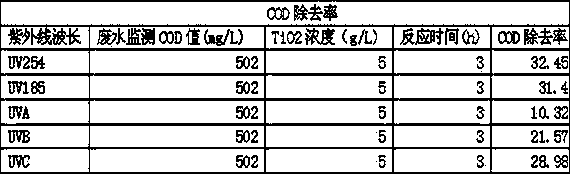

Examples

Embodiment 2

[0057] When containing heavy metal ion in waste water, the present invention comprises the following steps:

[0058] 1. Detect the composition, content and COD value of heavy metal ions in wastewater, and make records respectively;

[0059] 2. Determine the dosage of the catalyst and the ultraviolet irradiation time according to the COD value of the wastewater; the catalyst is TiO2, CdS, V2O5.

[0060] 3 Determine the composition and dosage of the replacement reagent according to the composition and content of heavy metal ions.

[0061] 4. Pass the waste water into the water storage tank, and add the catalyst in the water storage tank to mix the catalyst and the waste water evenly;

[0062] 5. Pass air or ozone into the uniformly mixed wastewater; the reaction device is the same as the UV photocatalytic oxidation reaction system in Step 4 in Example 1.

[0063] 6. The wastewater entering the reaction device is irradiated with ultraviolet radiation in the UVC~UVD band, prefer...

Embodiment 3

[0073] In Example 2, the removal of heavy metal ions in step 8 and the removal of organic matter by UV photocatalytic oxidation in step 6 can be interchanged, first remove heavy metal ions in wastewater, and then remove organic matter. It can avoid the situation that in the second embodiment, when the organic matter is removed in step 6, the heavy metal ions will also absorb part of the ultraviolet energy, avoiding the waste of ultraviolet energy, improving the energy utilization rate, and improving the decomposition efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com