Plugging agent for deep profile control and water plugging and preparation method thereof

A technology for deep profile control and water use, which is applied in the direction of chemical instruments and methods, and drilling compositions. Serious problems, to achieve the effect of fast gelation time, weak gelation strength, and reduced leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

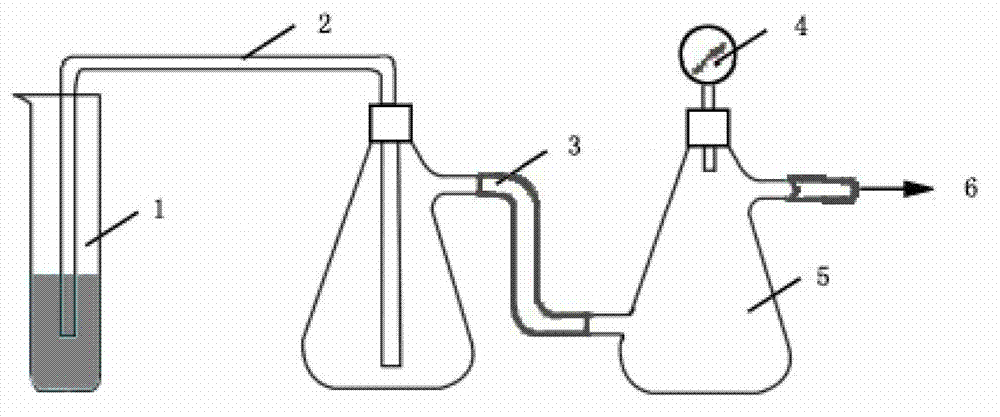

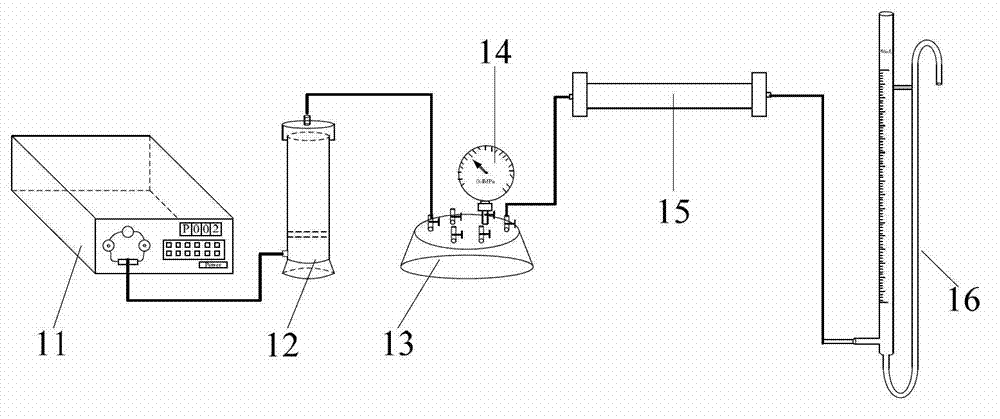

Method used

Image

Examples

Embodiment 1

[0050] Plugging agent for deep profile control and water plugging, raw material composition:

[0051] Partially hydrolyzed polyacrylamide 0.15%, potassium dichromate 0.1%, sodium sulfite 0.2%, hexamethylenetetramine 0.15%, phenol 0.12%, ammonium chloride 0.1%, the balance water.

[0052] Preparation:

[0053] Take each component according to the ratio, add partially hydrolyzed polyacrylamide powder to an appropriate amount of water and stir evenly to make a solution with a concentration of 5000mg / L, and mature it at room temperature for 5 hours, then add the matured partially hydrolyzed polyacrylamide mother liquor to the remaining amount Stir in water at 26°C for 0.5h to obtain a partially hydrolyzed polyacrylamide diluted solution; then add potassium dichromate, sodium sulfite, hexamethylenetetramine, phenol, and ammonium chloride in proportion to dilute In the solution, stir at 26°C for 0.5h to obtain the plugging agent for deep profile control and water plugging.

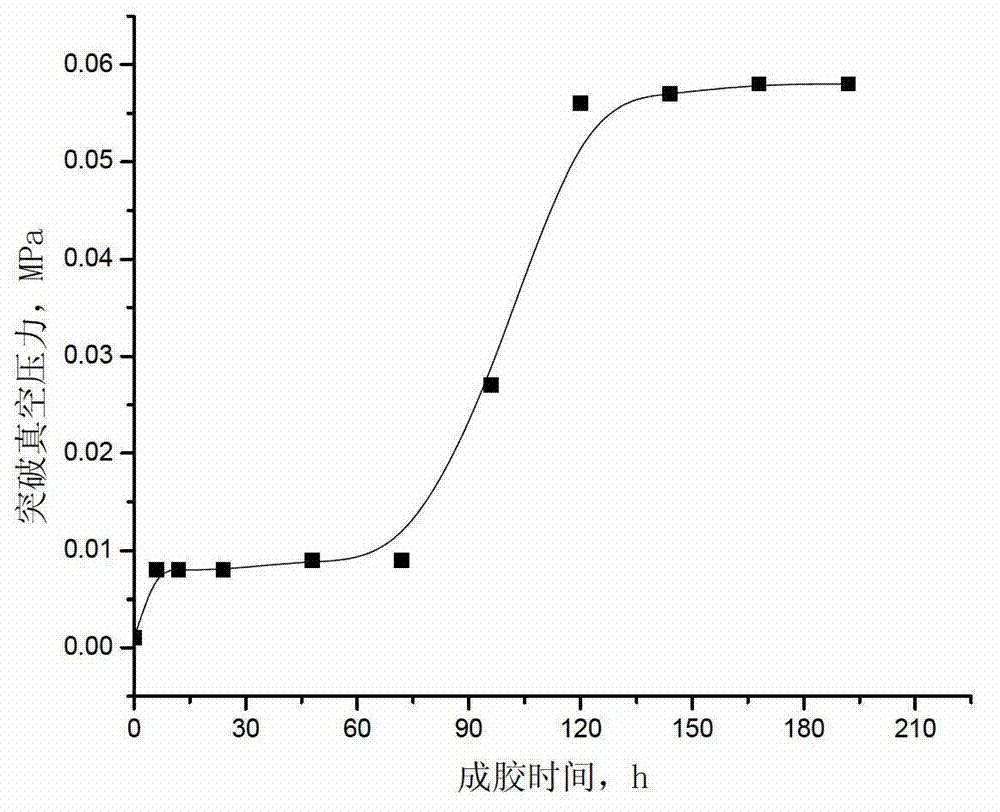

[0054...

Embodiment 2

[0056] As described in Example 1, the difference is that the plugging agent raw material consists of:

[0057] Partially hydrolyzed polyacrylamide 0.20%, potassium dichromate 0.08%, sodium sulfite 0.16%, hexamethylenetetramine 0.10%, phenol 0.08%, ammonium chloride 0.10%, the balance water.

[0058] Test results of the obtained plugging agent: at 60°C, the first gelation time of the plugging agent system is about 46 hours, and the second gelation time is about 285 hours; the core (permeability 1.11μm 2 ) breakthrough pressure gradient (plugging agent injection volume: 0.3PV) is 10MPa / m; the core plugging rate is 97.1%; after 10PV injection water scours, the plugging agent has a plugging rate of 92.8% on the core.

Embodiment 3

[0060] As described in Example 1, the difference is that the plugging agent raw material consists of:

[0061] Partially hydrolyzed polyacrylamide 0.25%, potassium dichromate 0.08%, sodium sulfite 0.16%, hexamethylenetetramine 0.10%, phenol 0.08%, ammonium chloride 0.10%, and the balance water.

[0062] Test results of the plugging agent obtained: at 60°C, the first gelation time of the plugging agent system is about 6 hours, and the second gelation time is about 150 hours; the core (permeability 1.08μm 2 ) breakthrough pressure gradient (plugging agent injection volume is 0.3PV) is 12MPa / m; the core plugging rate is 98.8%; after 10PV injection water scours, the plugging agent has a plugging rate of 93.4% on the core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure gradient | aaaaa | aaaaa |

| Core plugging rate | aaaaa | aaaaa |

| Core plugging rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com