Aluminum alloy with army-green micro-arc oxidation ceramic membrane on surface and preparation method of aluminum alloy

A micro-arc oxidation and aluminum alloy technology, applied in the direction of anodization, can solve the problems of black spots on the green ceramic film substrate, light color of the green ceramic film, and light green surface on the surface, etc., and achieves low cost, not easy to fade, and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

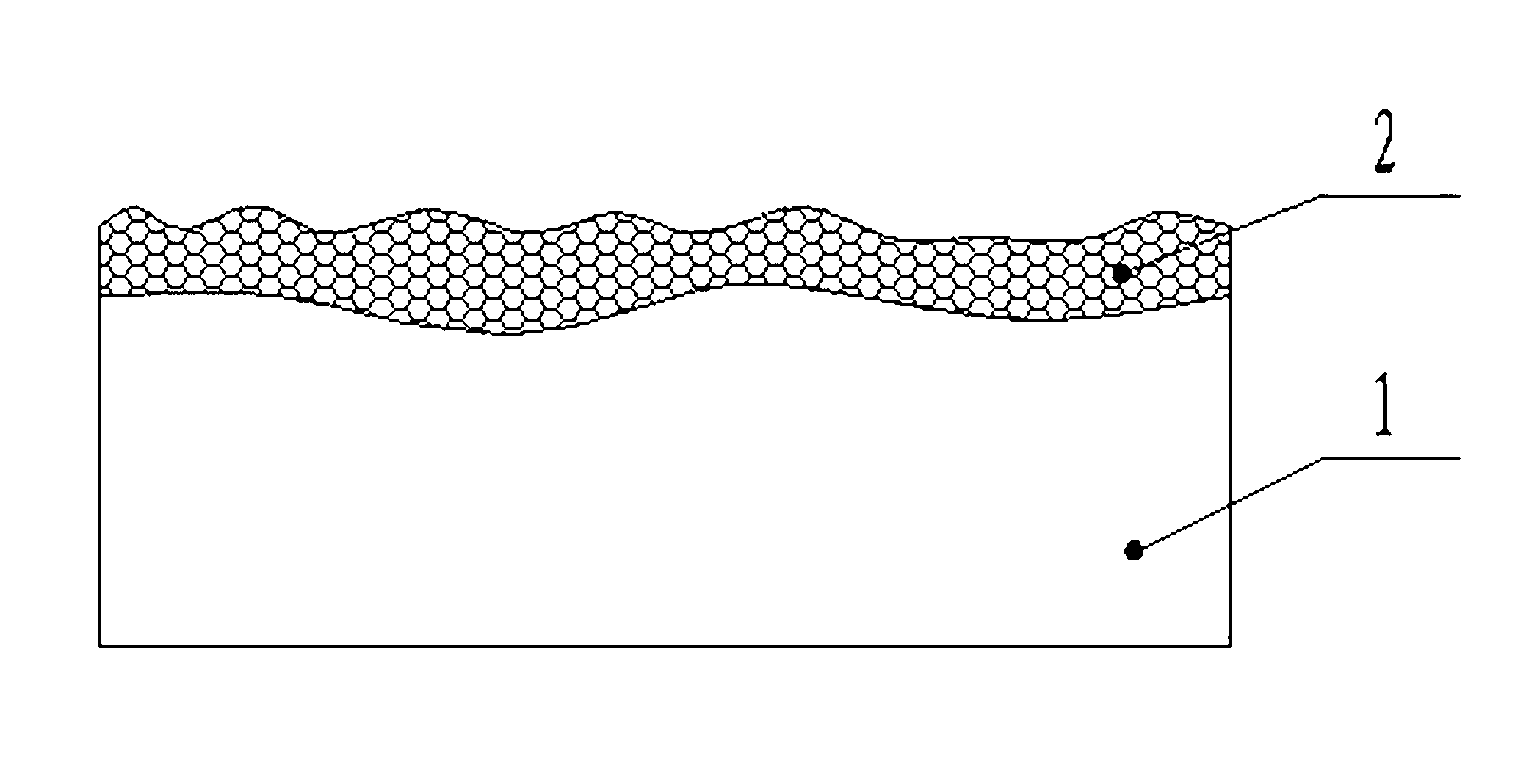

[0022] refer to figure 1 , the present invention is an aluminum alloy with a military green micro-arc oxidation ceramic film on the surface, which is composed of an aluminum alloy substrate 1 and a military green ceramic film 2 coated on the surface of the aluminum alloy substrate 1 .

[0023] Aluminum alloy substrate: 6061 aluminum alloy, size: 30mm×20mm×3mm.

[0024] The preparation method of the present invention is:

[0025] (1) Inject the alkaline electrolyte mixed according to the specific composition and concentration into the PVC plastic tank, stir evenly at 10~20°C, and use it after standing for 1~2 hours;

[0026] The weight of each component of the alkaline electrolyte and the total volume ratio of the electrolyte are: sodium phosphate 25g / L, sodium hexametaphosphate 15g / L, sodium hydroxide 4g / L, disodium edetate 3g / L, Potassium dichromate 3g / L, sodium carbonate 4g / L, sodium lauryl sulfate 2g / L, hydrogen peroxide 2g / L, pH value 12-14;

[0027] (2) Use 400#, 600#,...

Embodiment 2

[0032] Preparation of an aluminum alloy with a military green micro-arc oxidation ceramic film on the surface, the aluminum alloy substrate: 6061 aluminum alloy, size: 30mm×20mm×3mm.

[0033] The weight of each component of the alkaline electrolyte and the total volume ratio of the electrolyte are: sodium phosphate 30g / L, sodium silicate 30g / L, sodium hexametaphosphate 20g / L, sodium hydroxide 3g / L, ethylenediaminetetra Disodium acetate 4g / L, potassium dichromate 3.5g / L, sodium carbonate 4g / L, sodium lauryl sulfate 3g / L, hydrogen peroxide 2g / L; micro-arc oxidation time is 20min, current density is 10 A / dm 2 , the rest of the preparation method is the same as in Example 1, the thickness of the prepared ceramic film is 20.2 μm, and the microhardness is 1700HV.

Embodiment 3

[0035] Preparation of an aluminum alloy with a military green micro-arc oxidation ceramic film on the surface, the aluminum alloy substrate: 6061 aluminum alloy, size: 20mm×15mm×1mm.

[0036] The ratio of the weight of each component of the alkaline electrolyte to the total volume of the electrolyte is: sodium silicate 40g / L, sodium hexametaphosphate 18g / L, sodium hydroxide 4g / L, disodium edetate 2g / L , potassium dichromate 4g / L, sodium carbonate 10g / L, sodium lauryl sulfate 5g / L, hydrogen peroxide 2g / L; the micro-arc oxidation time is 45min, and the current density is 10 A / dm 2 , the rest of the preparation method is the same as in Example 1, the thickness of the prepared ceramic film is 21.4 μm, and the microhardness is 1700HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com